Floor splicing and fixing structure and mounting method thereof

A technology for fixing structures and floors, applied to building structures, floors, buildings, etc., can solve problems such as cumbersome installation process and complex structure, and achieve the effects of simple structure, avoiding wet work, and reducing overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

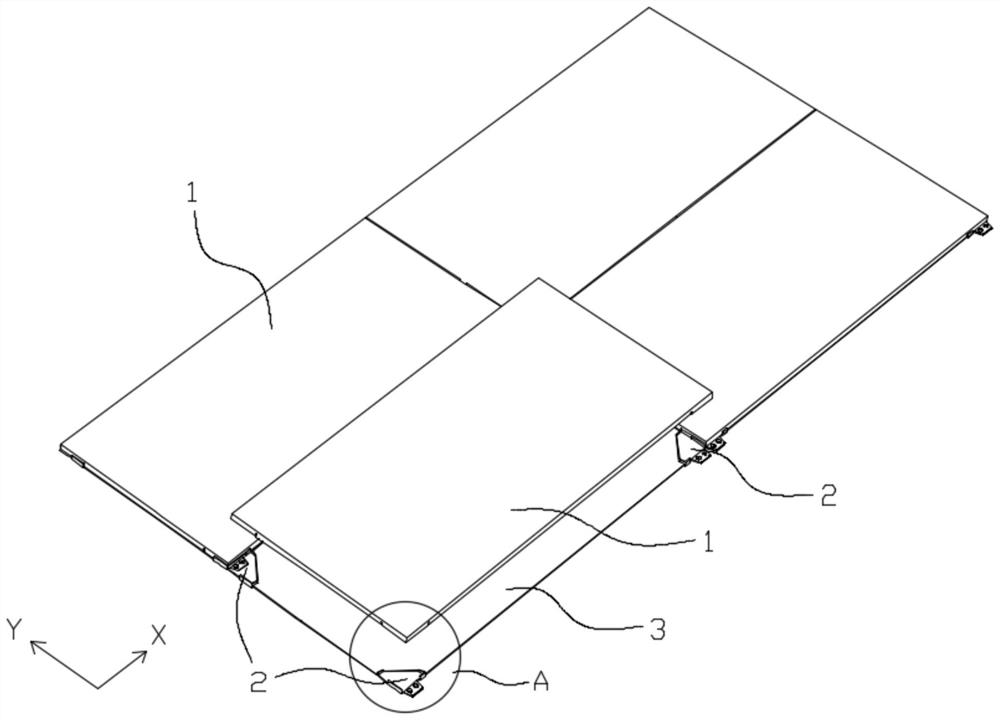

[0044] Such as figure 1 As shown, the embodiment of the present invention provides a floor splicing and fixing structure, including a floor 1 and a connecting piece 2, the floor 1 is rectangular, several floors 1 are arranged in a matrix, and the connecting piece 2 is installed at a right angle of the floor 1 , adjacent floors 1 are spliced to each other through connectors 2 .

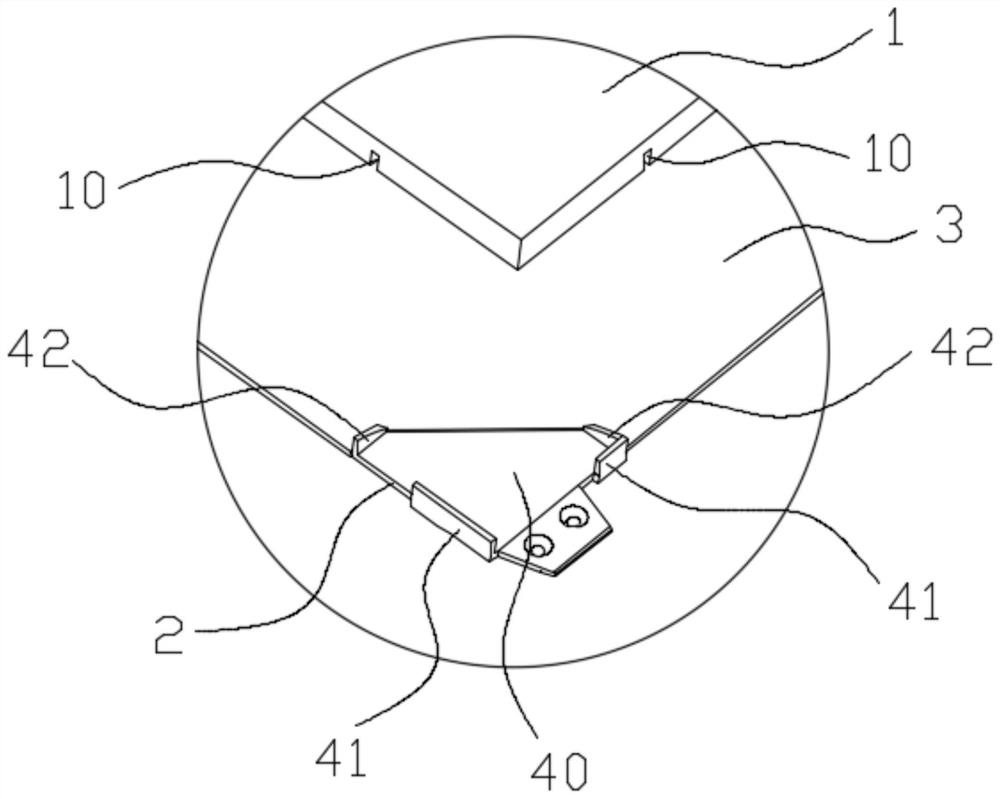

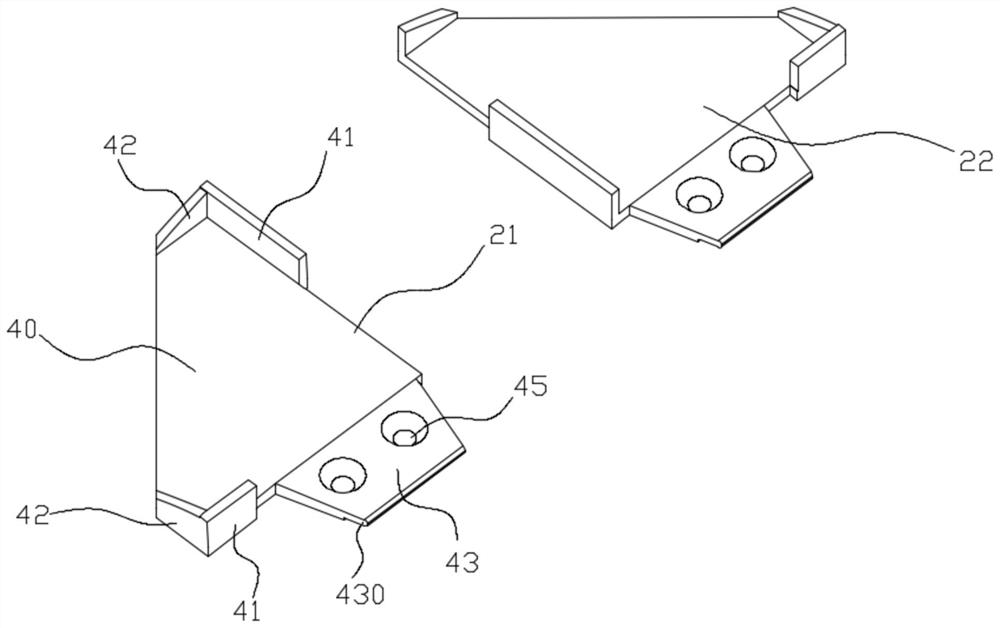

[0045] Specifically, such as figure 2 As shown, the connecting piece includes a base plate 40 arranged horizontally, and the base plate 40 has two right-angled sides. Two limiting side plates 41 and two positioning plates 42 are connected to the base plate 40 vertically. The two limiting side plates 41 are respectively arranged along the edges of the two right-angled sides, and the two positioning plates 42 are vertically connected to the ends of the two right-angled sides (ie, the other end away from the intersection point of the right angles).

[0046] The bottom surface near each right angle of...

Embodiment 2

[0059] The embodiment of the present invention provides the installation method of the above-mentioned floor splicing and fixing structure, which is mainly aimed at the situation of using the first male connector 21 and the first female connector 23 for splicing. Similarly, the second male connector 22 and the second female connector 24 can also be spliced by the same method.

[0060] Such as Figure 5 As shown, specifically, the installation method of this embodiment includes:

[0061] S1. Among the two adjacent floors 1 along the Y axis, select one of the floors 1, install the first male connector 21 at its right angle, and then place it on the ground;

[0062] S2, fixing the splicing plate 43 of the first male connector 21 on the ground by screws;

[0063] S3, on the side of the splicing plate 43 of the first male connector 21, place another floor 1 above the first female connector 23 and install and fix it;

[0064] S4. Move the first female connecting piece 23 descri...

Embodiment 3

[0066] The embodiment of the present invention provides an installation method of the above-mentioned floor splicing and fixing structure, which is mainly aimed at using the first male connector 21, the second male connector 22, the first female connector 23 and the second female connector at the same time. The case where the connector 24 is multi-directionally spliced.

[0067] Such as Figure 6 As shown, specifically, the installation method of this embodiment includes:

[0068] S1. Among the four adjacent spliced floors 1, select one of the floors 1, install the first male connector 21 at its right angle, and then place it on the ground; and screw the splicing board of the first male connector 21 43 is fixedly connected to the ground;

[0069] S2. On the side of the splicing plate 43 of the first male connector 21, place the second floor 1 above the first female connector 23 and install and fix it;

[0070] S3. Set the splicing groove 44 of the first female connector 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com