Liquid carbon dioxide fire extinguisher inflatable equipment

A technology of liquid carbon dioxide and inflatable equipment, applied in the field of fire extinguishers, can solve the problems of unsafe pipelines, the inflatable head is not easy to disengage the inflatable port, hidden dangers, etc., and achieves the effects of convenient connection, easy maintenance, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

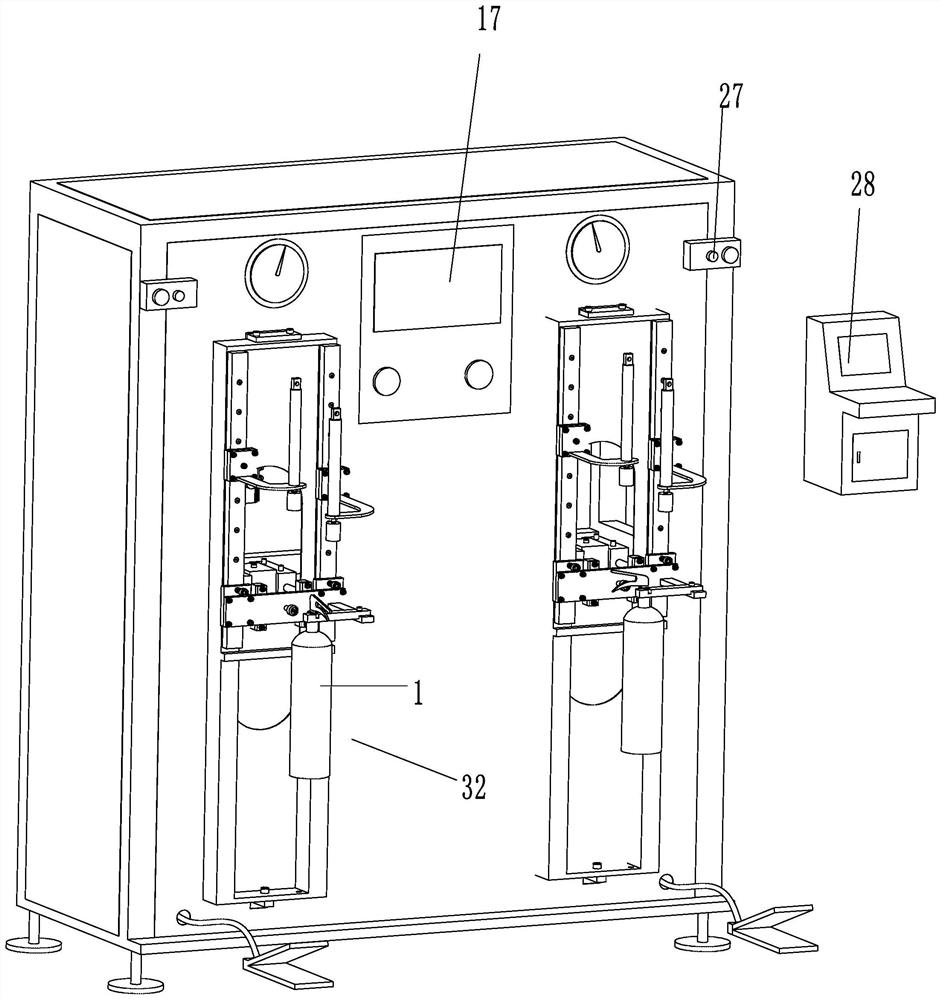

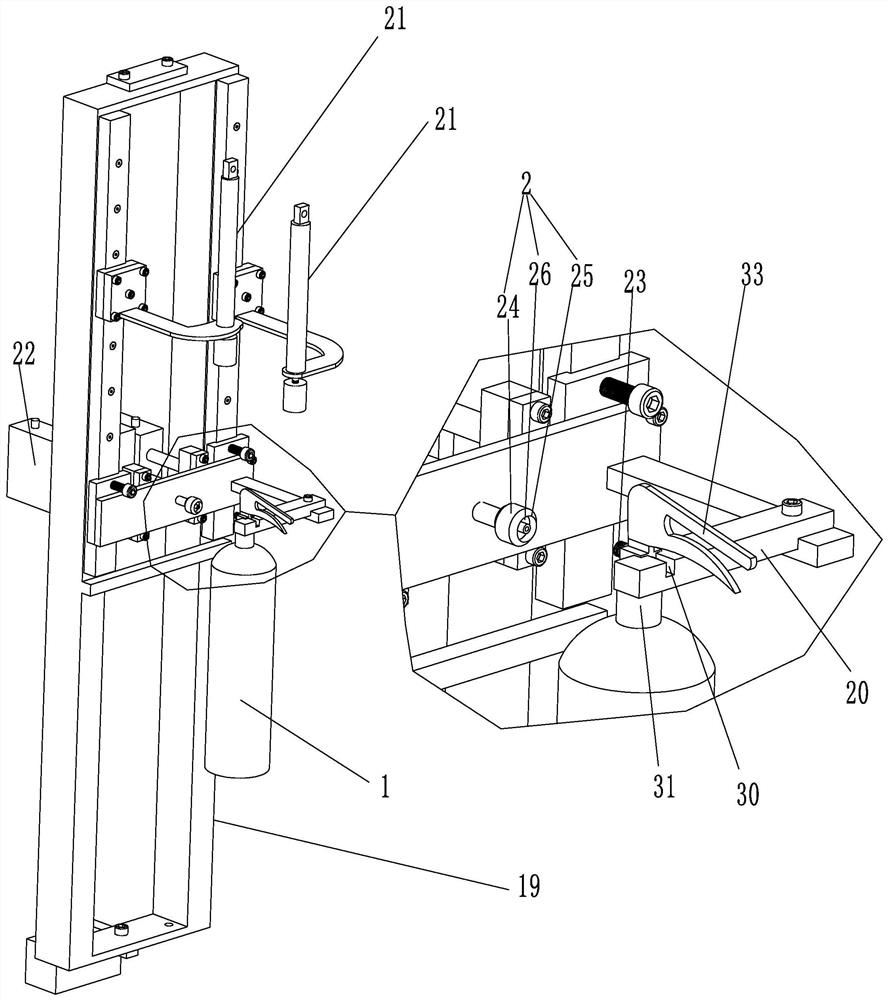

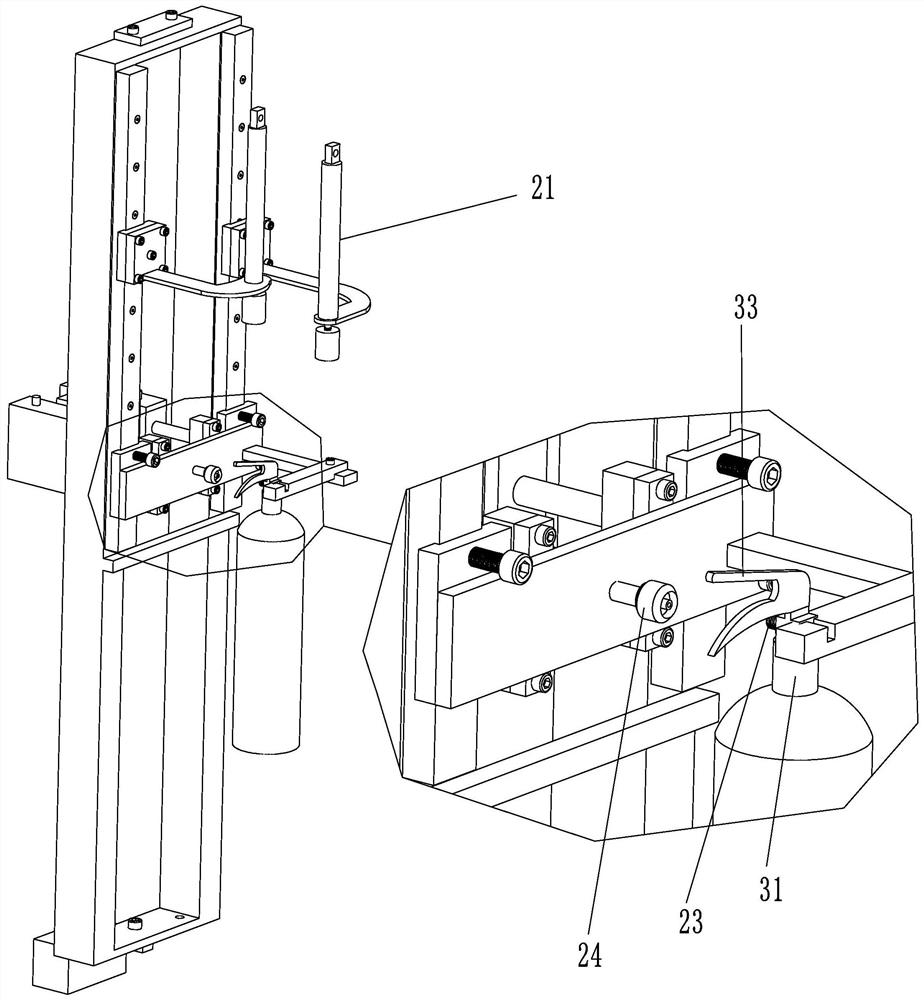

[0030] see Figure 1 to Figure 6 , a liquid carbon dioxide fire extinguisher charging equipment, including a station 32 for charging the fire extinguisher 1, a gas storage tank 3, and a booster pump 4 connected to the gas outlet of the gas storage tank 3, used to connect the booster pump 4 and the storage tank The air return pipe 5 of the air inlet of the air tank 3, the automatic valve 6 located on the air return pipe 5, the air pressure sensor for detecting the inflation air pressure, the display screen 17 for displaying the inflation parameters, the inflation button 27, and the control host 28 .

[0031] The station includes an inflation head 2 for connecting to the fire extinguisher 1 and charging, an inflation pipe 7 connected to the inflation head 2 at one end, an exhaust pipe 8 connected to the inflation pipe 7 at one end, and an exhaust valve on the exhaust pipe 8 9. The inflation valve 10 located on the inflation pipe 7; also includes a fixing mechanism for fixing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com