A water-cooled air-cooled heat pump module unit with ejection enthalpy

An air-cooled heat pump and water-cooled technology, which is applied in the direction of refrigerators, refrigeration components, compressors, etc., can solve the problems of unit heating efficiency, attenuation of heating capacity, and high power consumption of compressors, etc., to achieve small modularization , Refrigeration and heating efficiency, and the effect of refrigeration and cooling integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

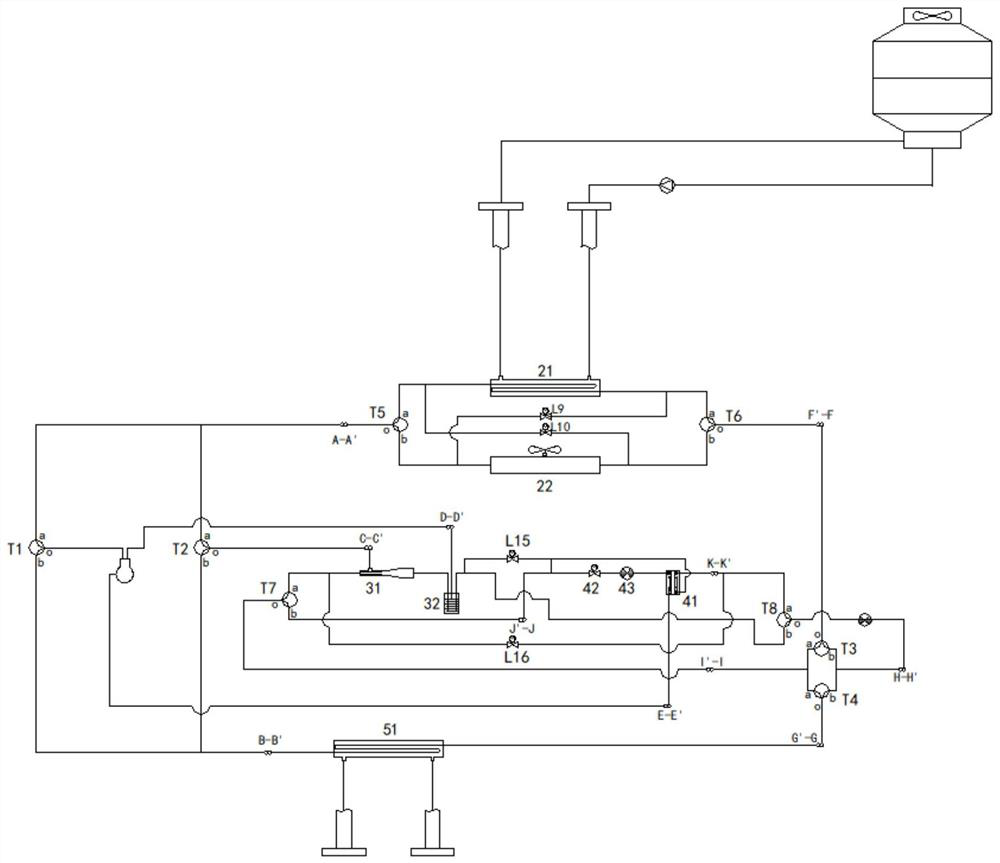

[0092] refer to Figure 19 , air-cooled ejection cooling mode:

[0093] Refrigerant circulation system: the first three-way valve T1oa is connected; the second three-way valve T2ob is connected; the third three-way valve T3ao is connected; the fourth three-way valve T4ob is connected; the fifth three-way valve T5bo is connected; The end of the sixth three-way valve T6bo is connected; the end of the seventh three-way valve T7ao is connected; the end of the eighth three-way valve T8bo is connected; the enthalpy increasing solenoid valve 42 is closed.

[0094] Refrigerant circulation path:

[0095] In the high pressure cycle, the refrigerant flows through the steam injection port of the compressor 11, the first valve port o and the second valve port a of the first three-way valve T1, and the fifth three-way valve T5 of the cold and heat source heat exchanger module. The valve port o and the third valve port b, the air source heat exchanger 22, the third valve port b and the fir...

Embodiment 2

[0102] refer to Figure 20 , water-cooled ejection cooling mode:

[0103] Refrigerant circulation system: the first three-way valve T1oa is connected; the second three-way valve T2ob is connected; the third three-way valve T3ao is connected; the fourth three-way valve T4ob is connected; the fifth three-way valve T5ao is connected; The end of the sixth three-way valve T6ao is connected; the end of the seventh three-way valve T7ao is connected; the end of the eighth three-way valve T8bo is connected; the enthalpy increasing solenoid valve 42 is closed.

[0104] Refrigerant circulation path:

[0105] In the high pressure cycle, the refrigerant flows through the steam injection port of the compressor 11, the first valve port o and the second valve port a of the first three-way valve T1, and the fifth three-way valve T5 of the cold and heat source heat exchanger module. A valve port o and a second valve port a, the water source heat exchanger 21, the second valve port a and the f...

Embodiment 3

[0112] refer to Figure 21 , air pre-cooled cold ejection cooling mode:

[0113] Refrigerant circulation system: the first three-way valve T1oa is connected; the second three-way valve T2ob is connected; the third three-way valve T3ao is connected; the fourth three-way valve T4ob is connected; the fifth three-way valve T5bo is connected; The end of the sixth three-way valve T6ao is connected; the end of the seventh three-way valve T7ao is connected; the end of the eighth three-way valve T8bo is connected; the enthalpy increasing solenoid valve 42 is closed.

[0114] Refrigerant circulation path:

[0115] In the high pressure cycle, the refrigerant flows through the steam injection port of the compressor 11, the first valve port o and the second valve port a of the first three-way valve T1, and the fifth three-way valve T5 of the cold and heat source heat exchanger module. The valve port o and the third valve port b, the air source heat exchanger 22, the second solenoid valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com