Gate flow cross section flow measuring method

A water-passing section and gate technology, which is applied in the measurement of flow/mass flow, measuring device, fluid velocity measurement, etc., can solve the problem of lack of specific methods for flow velocity measurement, limit the application of gate water measurement, and cannot cover flow velocity, etc. Continuous online measurement, automatic measurement, high-precision calculated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

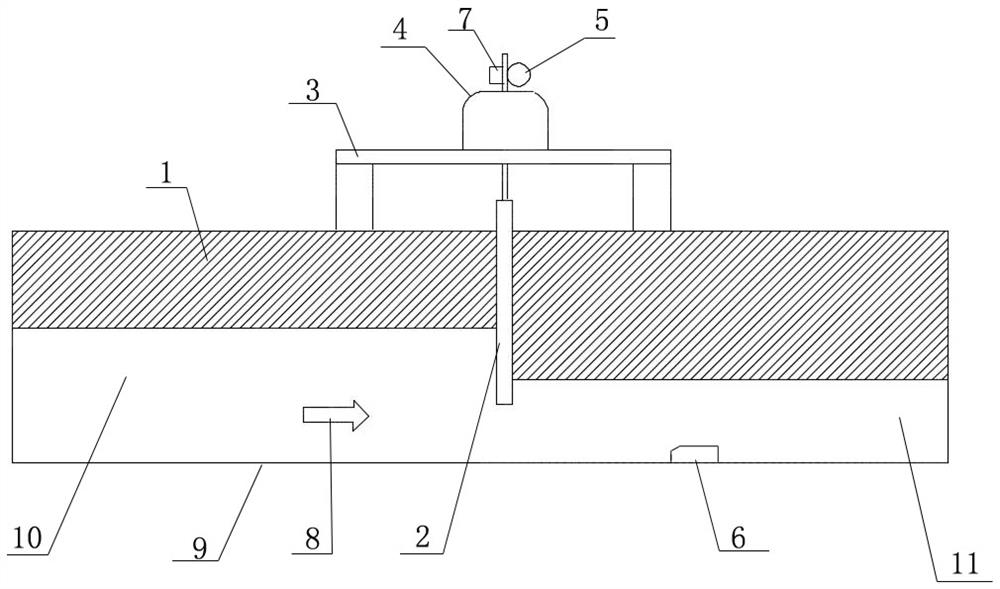

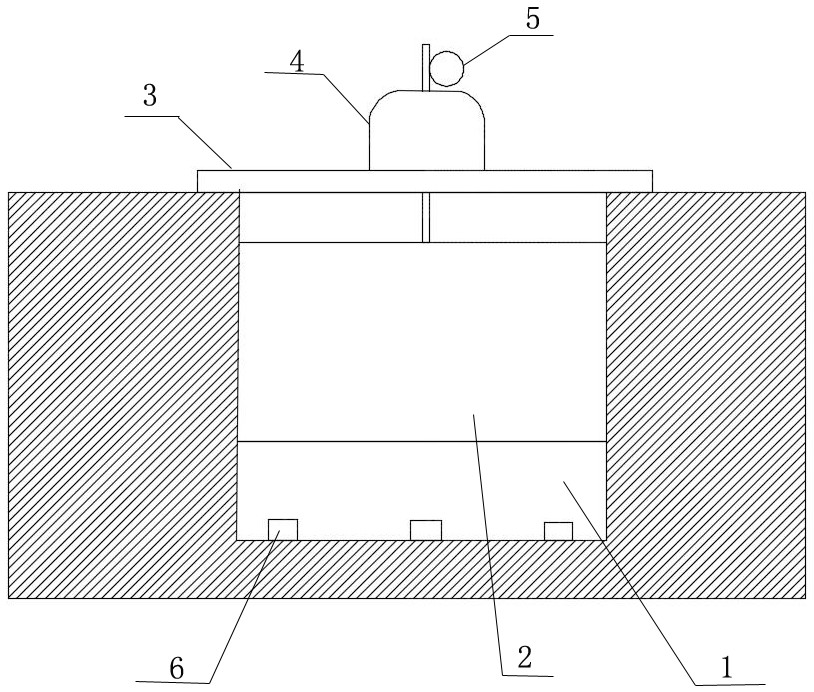

[0027] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0028] A method for measuring flow at a cross-section of a gate, comprising the following steps:

[0029] ① Doppler vertical profile flow velocity sensors are installed on the bottom surface behind the gate, and are arranged in multiple vertical lines, with at least one quantity;

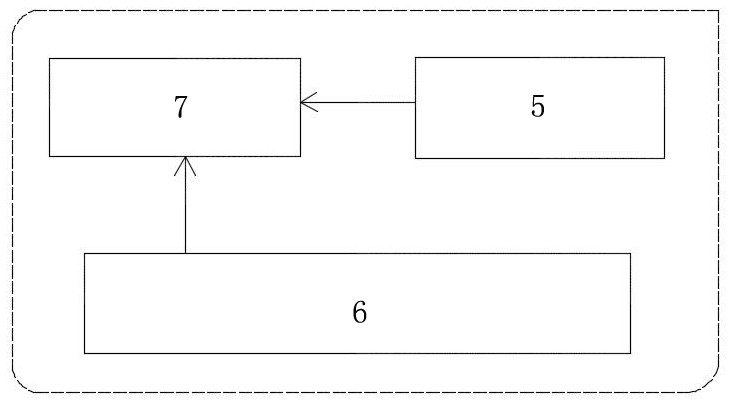

[0030] ②The Doppler vertical profile flow velocity sensor faces the ram and emits an ultrasonic Doppler multi-point flow velocity detection beam obliquely upward. The number and spacing of the flow velocity detection points on the beam can be set, due to the beam angle during manufacture It has been determined that the actual velocity value of each point on the sag line of the ram is the cosine value of the beam angle 12;

[0031] ③ Within the coverage of the detection beam of the Doppler vertical profile flow velocity sensor, the flow velocity detection point includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com