Method, system and device for quickly checking digital-analog hole site matching condition and storage medium

A rapid inspection and die hole technology, which is applied in manufacturing computing systems, image data processing, image analysis, etc., can solve the problems of huge amount of operation, difficulty in ensuring accuracy, and labor cost, so as to achieve flexible application, avoid errors, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

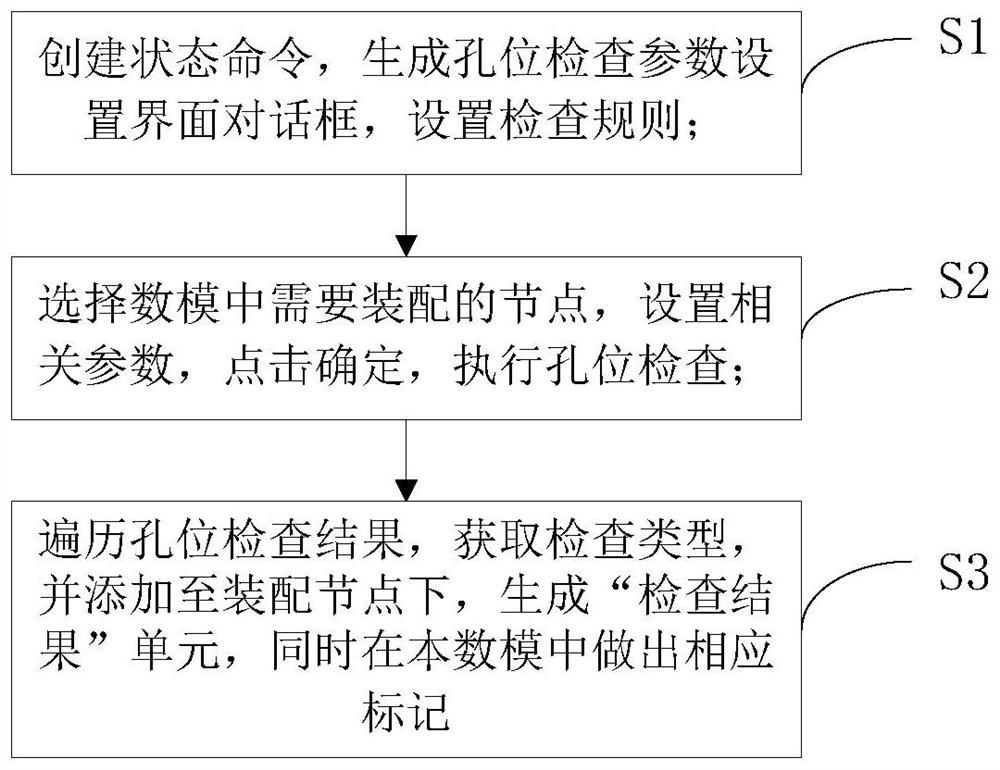

[0064] see figure 1 , the embodiment of the present invention includes:

[0065] A method for quickly checking the matching of digital-analog holes, comprising the following steps:

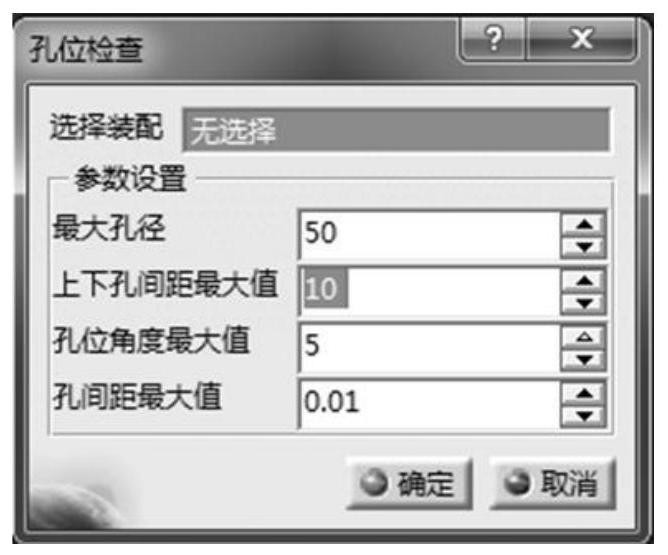

[0066] S1: create state command, generate hole position inspection parameter setting interface dialog box, such as figure 2 As shown, set the inspection rules;

[0067] Specifically, the specific steps for setting inspection rules include:

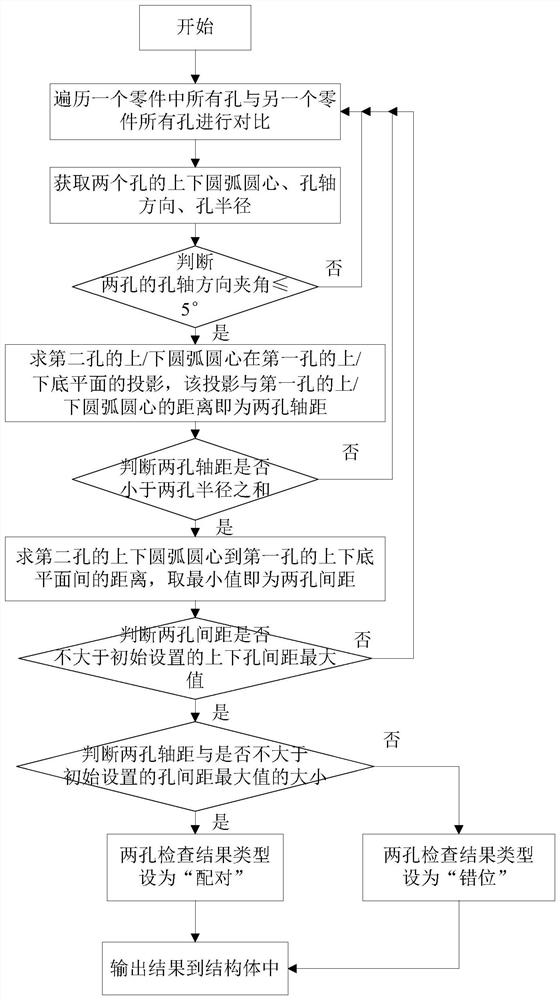

[0068] S101: Obtain the project path and configuration file path, and read thread specifications, bolt hole size information, and pin hole size information from the configuration file;

[0069] S102: Set path element agent a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com