Movable assembly type plant planting frame and using method thereof

A planting frame and assembled technology, applied in the fields of botanical equipment and methods, biochemical equipment and methods, bioreactors/fermenters for specific purposes, etc. damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

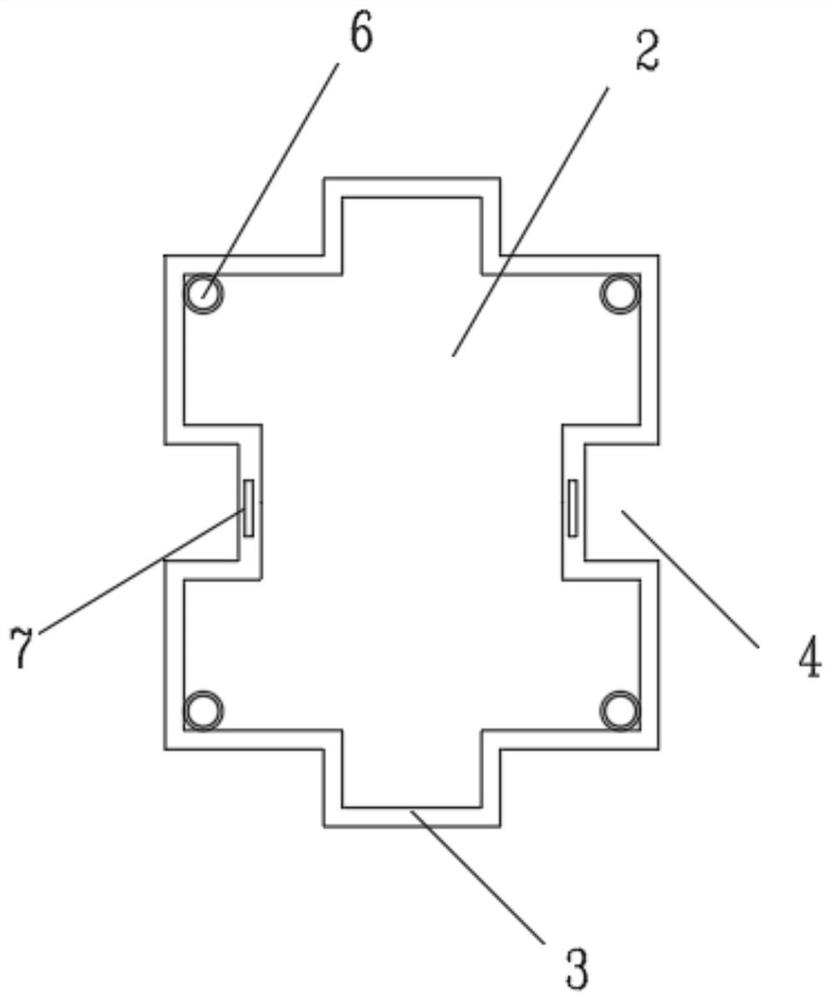

[0019] Such as figure 1 As shown, in this embodiment, a movable assembled plant planting frame includes a hollow frame body and a planting matrix arranged in the frame body, and the frame body is a rectangular parallelepiped structure.

[0020] During construction, the planting matrix is packed into the planting frame, the plants are implanted in the planting matrix, and a plurality of planting frames are arranged in an array according to design requirements. Since the planting frames are in the shape of a cuboid, when the planting frames need to be densely placed, the adjacent planting frames can be fitted together, reducing or avoiding gaps between adjacent planting frames, improving the space utilization rate, and increasing the density of plants. When the planting frames are transported, the planting frames can also be tightly fitted, thereby avoiding collisions between adjacent planting frames, improving the utilization rate of the transport space, and improving the tra...

Embodiment 2

[0024] On the basis of the above embodiments, in this embodiment, the upper surface of the frame body is provided with several positioning protrusions, and the lower surface of the frame body is provided with several positioning grooves that can be fitted with the positioning protrusions. In order to provide more growth space for the plant root system, the planting frame can be multi-layered to increase the volume. The bottom of the bottom planting frame can be sealed or not. The back cover is to maintain the connected state with the lower planting frame. The cooperation between the positioning protrusion and the positioning groove can facilitate the rapid positioning and installation of the multi-layer planting frame, and restrict the mutual movement of the upper and lower two-layer planting frames along the horizontal direction, thereby improving the overall stability of the planting frame.

[0025] In this embodiment, several locking sleeves arranged vertically are arranged...

Embodiment 3

[0028] On the basis of the above embodiments, in this embodiment, the upper surface of the frame body is provided with a lifting ring. Using the lifting ring as the stress point makes it easy to lift the planting frame upwards, so that a single planting frame can be taken out when it needs to be replaced or repaired. Using the lifting ring is also easy to connect with hooks, ropes and other structures, so that remote operate.

[0029] In this embodiment, the lifting ring is connected with a threaded rod, and the threaded rod is threaded with the frame. When setting up a multi-layer planting frame, the lifting ring is connected to the topmost planting frame to avoid unnecessary gaps between the planting frames caused by the lifting ring being set between two layers of planting frames.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com