Novel red pitaya yoghourt and preparation method thereof

A technology of red pitaya and yogurt, which is applied in the field of new red pitaya yogurt and its preparation, can solve the problems of restricting the deep processing of red pitaya, unstable anthocyanins, and only a small amount, and achieve pink color, smooth taste, and texture delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

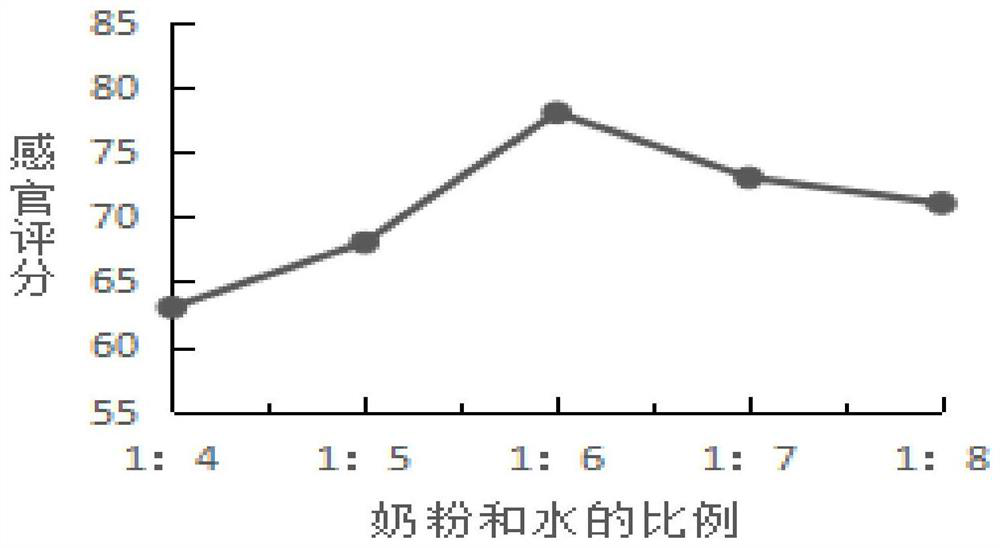

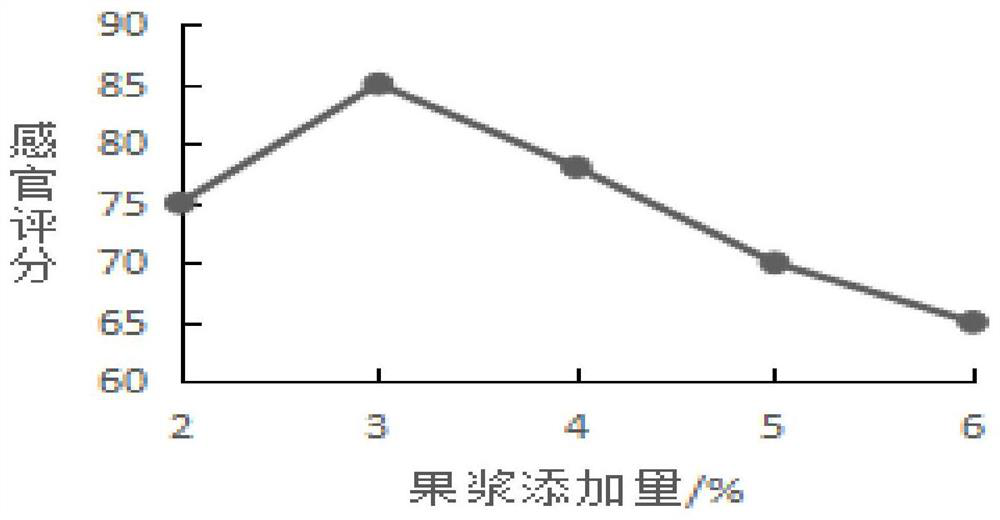

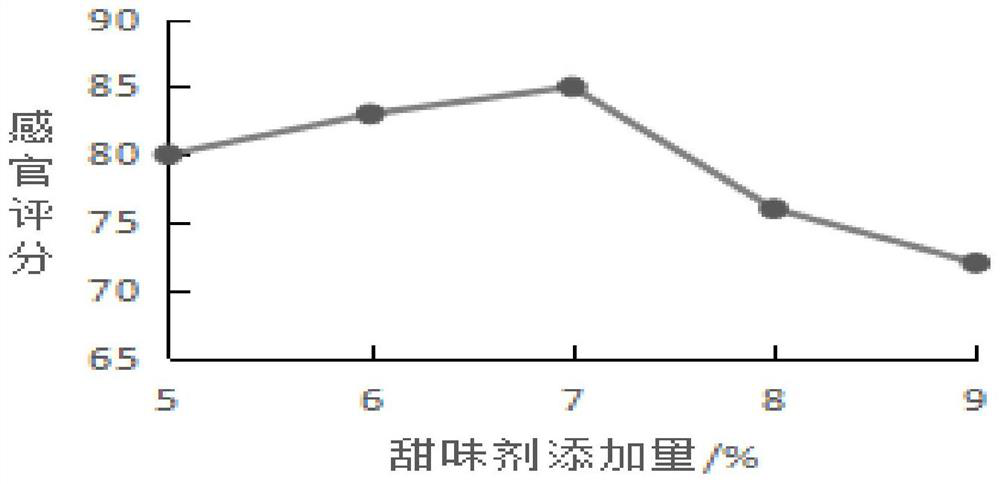

Method used

Image

Examples

Embodiment 1

[0073] A novel red pitaya yoghurt comprises the following raw materials in mass percentage: 10% of whole milk powder, 80% of warm water, 1% of red pitaya pulp, and 9% of white sugar.

[0074] A preparation method of novel red dragon fruit yogurt, comprising the steps of:

[0075] S1, preparing red dragon fruit pulp

[0076] Choose a red dragon fruit with no spots or lesions, wash to remove dust and impurities, peel and cut into cubes, then put the pulp into the wall breaking machine for 2 minutes, after filtering, add color-protecting agent, and then put it in a constant temperature water bath at 70°C Sterilize for 15 minutes and cool down to 42°C;

[0077] S2, deployment, homogenization

[0078] Prepare whole milk powder, warm water and white granulated sugar in a certain proportion to form an emulsion, and then perform homogenization;

[0079] S3, sterilization, cooling

[0080] After sterilizing at 90°C for 10 minutes, cool down to 42°C;

[0081] S4, inoculation, ferme...

Embodiment 2

[0086] A novel red pitaya yogurt comprises the following raw materials in mass percentage: 10% of whole milk powder, 80% of warm water, 5% of red pitaya pulp, and 5% of white sugar.

[0087] A preparation method of novel red dragon fruit yogurt, comprising the steps of:

[0088] S1, preparing red dragon fruit pulp

[0089] Choose red dragon fruit with no spots or lesions, wash to remove dust and impurities, peel and cut into cubes, then put the pulp into a wall breaking machine to break the wall for 2 minutes, after filtering, add color-protecting agent, and then put it in a constant temperature water bath at 75°C Sterilize for 18 minutes and cool down to 42°C;

[0090] S2, deployment, homogenization

[0091] Prepare whole milk powder, warm water and white granulated sugar in a certain proportion to form an emulsion, and then perform homogenization;

[0092] S3, sterilization, cooling

[0093] After sterilizing at 90°C for 12 minutes, cool down to 45°C;

[0094] S4, inocu...

Embodiment 3

[0099] A novel red pitaya yoghurt comprises the following raw materials in mass percentage: 12.8% of whole milk powder, 77.2% of warm water, 3% of red pitaya pulp, and 7% of white sugar.

[0100] A preparation method of novel red dragon fruit yogurt, comprising the steps of:

[0101] S1, preparing red dragon fruit pulp

[0102] Choose a red dragon fruit with no spots or lesions, wash to remove dust and impurities, peel and cut into cubes, then put the pulp into a wall breaking machine to break the wall for 3 minutes, after filtering, add color-protecting agent, and then put it in a constant temperature water bath at 70°C Sterilize for 15 minutes and cool down to 42°C;

[0103] S2, deployment, homogenization

[0104] Prepare whole milk powder, warm water and white granulated sugar in a certain proportion to form an emulsion, and then perform homogenization;

[0105] S3, sterilization, cooling

[0106] After sterilizing at 90°C for 10 minutes, cool down to 42°C;

[0107] S4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com