A fast collection device and method for collecting and cleaning building formwork cutting waste

A technology of building templates and collection devices, applied in cleaning methods and appliances, cleaning methods using tools, cleaning methods using gas flow, etc., can solve the problems of centralized waste cleaning, dust explosion, safety hazards, etc., and reduce labor force The process of input and transmission is smooth and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

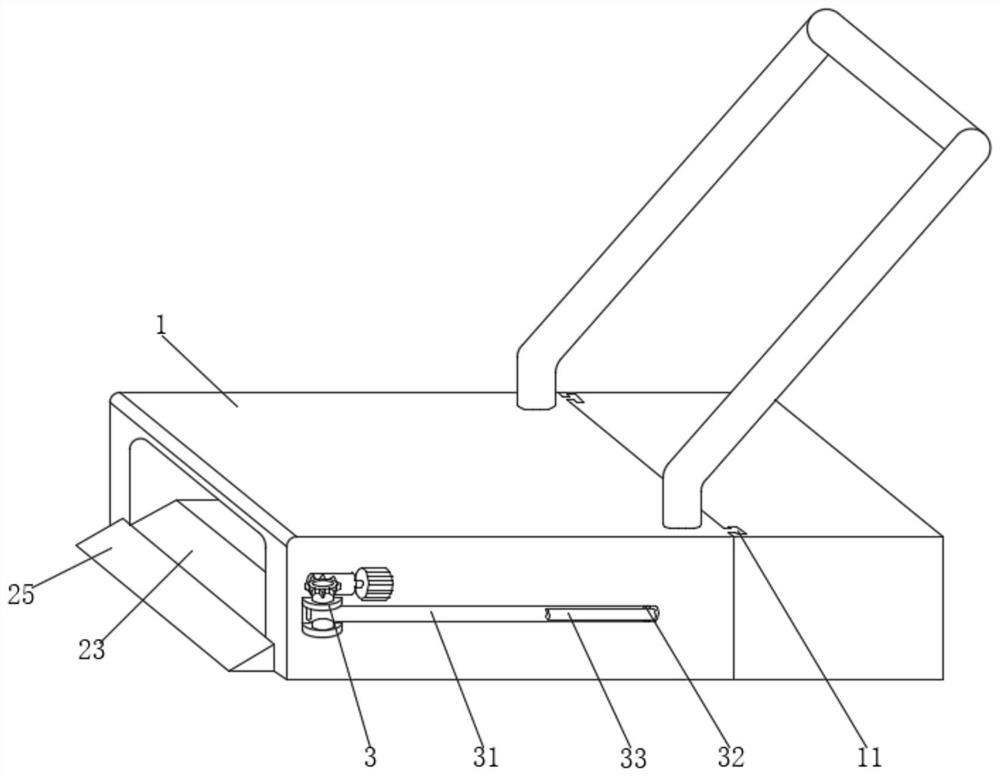

[0033] see Figure 1-5 , the present embodiment provides a device for quickly collecting building formwork cutting waste, including a collection bin 1, one end of the collection bin 1 is provided with a collection box for storing waste materials, and the bottom surfaces of the collection bin 1 and the collection box are both provided with rollers, collecting The bin 1 can move freely in the area where waste materials exist through the handle provided on its top surface, thereby making the collection and processing of waste materials more convenient.

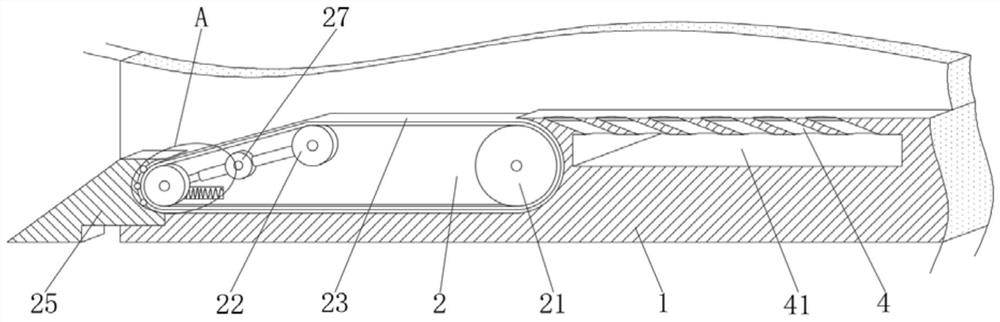

[0034] The end of the inner wall of the bottom side of the collection bin 1 close to the opening is provided with a mounting groove 2. The mounting groove 2 can enable the conveyor belt 23 to be installed in an inlaid manner, so that the non-working surface of the conveyor belt 23 does not contact the waste material, which helps the waste material in the collection bin. 1 smooth shipping inside.

[0035] The inside of the installa...

Embodiment 2

[0053] see Figure 1-3 , on the basis of embodiment 1, a further improvement has been made: the size of the waste produced during the cutting of the building formwork is different, there are large and small, and manual assistance is required for the smaller waste to be able to realize the waste to the interior of the collection bin 1 transfer.

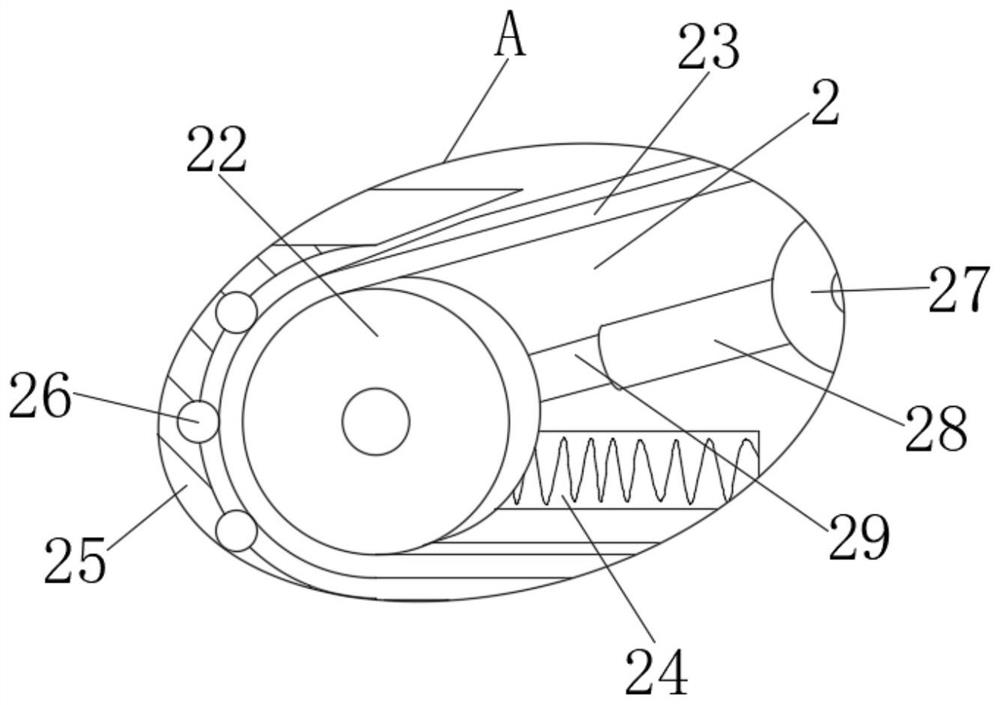

[0054] In order to further reduce the height difference between the end of the transmission belt 23 and the ground, the inner wall of the bottom side of the installation groove 2 is inserted with a movable platform 25 through the movable groove 24, and the movable platform 25 can adjust the distance between the transmission belt 23 and the ground. Supplementary, can eliminate the impact of height difference on the process of waste contacting the conveyor belt 23 .

[0055] An extension spring is arranged between one end of the movable platform 25 extending into the inside of the movable groove 24 and the inwall of the movable groove 2...

Embodiment 3

[0063] see Figure 6-7 , On the basis of Embodiment 1, a further improvement has been made: in order to further enhance the scope of the single disturbance of the telescopic rod 31 and the deflection rod 33 to waste.

[0064] Both the fixed cylinder 34 and the movable cylinder 35 are composed of a main rod 6 and an auxiliary rod 61. The auxiliary rod 61 is plugged into the inside of the main rod 6. The change in the length between the auxiliary rod 61 and the main rod 6 can directly change the overall length of the telescopic rod 31. The change of the length, and then change the radius of the sweeping range when the telescopic rod 31 deflects once, can change the range of the waste material.

[0065] In order to make the change of the length between the main rod 6 and the auxiliary rod 61 more convenient, one end of the auxiliary rod 61 extending into the main rod 6 is provided with a deformation groove 63, and the inside of the deformation groove 63 is integrally provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com