Building steel bar cutting device

A cutting device, a technology for building steel bars, applied in the directions of transportation and packaging, stacking of objects, etc., can solve problems such as affecting the normal use of steel bars, bending and deformation of steel bars, easy swinging and cluttering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

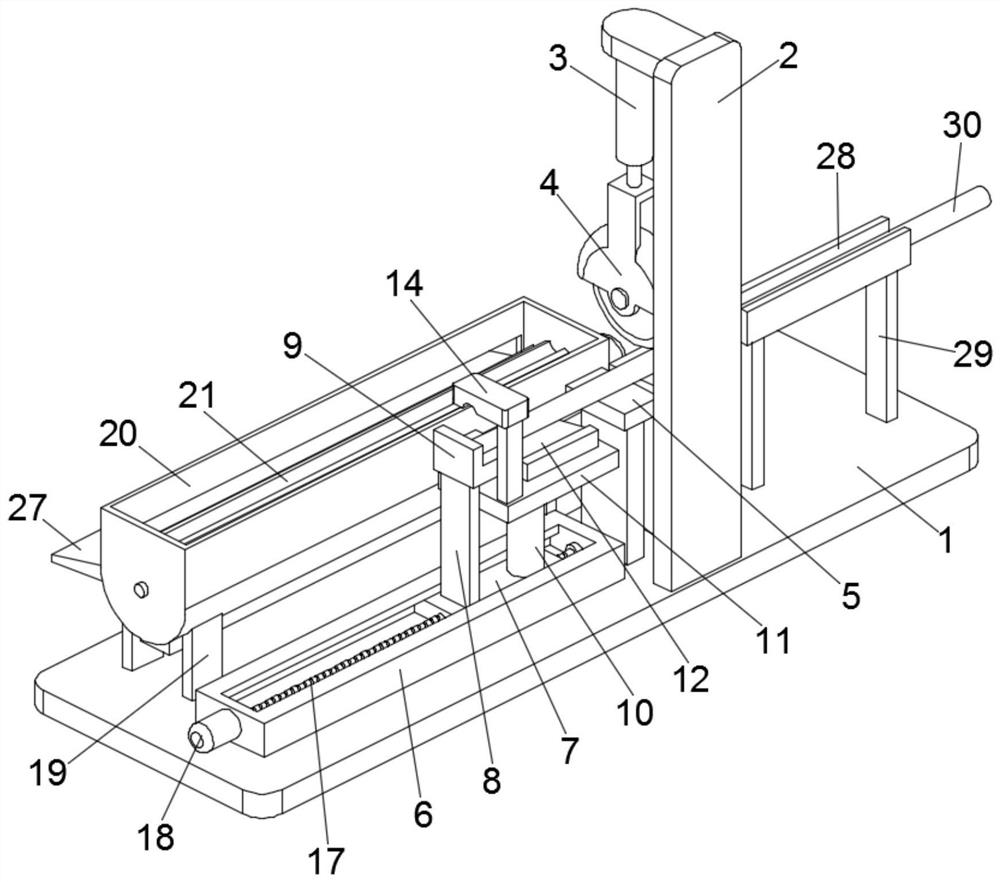

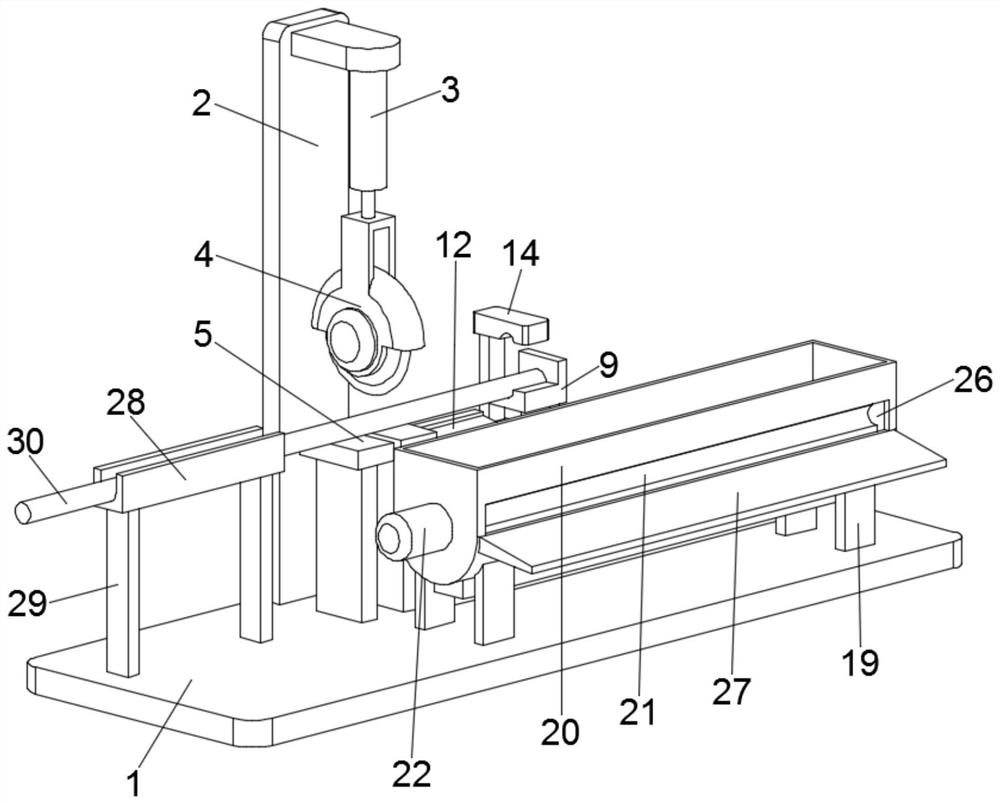

[0026] see Figure 1-2 , a construction reinforcement cutting device, comprising a base 1, a first support frame 2, a cutting machine 4 and a cutting table 5, the first support frame 2 and the cutting table 5 are fixedly installed on the base 1, the first support The top of the frame 2 is provided with a first driving cylinder 3, the lower end of the first driving cylinder 3 is equipped with a cutting machine 4, and the cutting machine 4 is located directly above the cutting table 5;

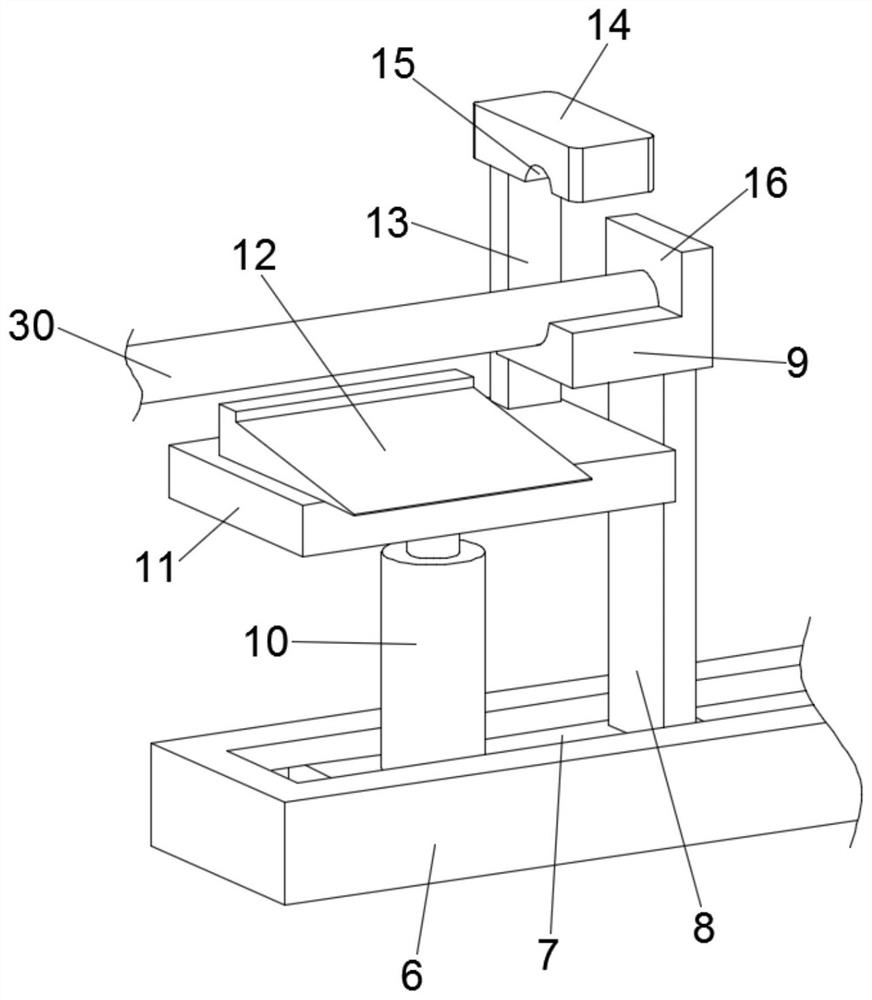

[0027] see image 3 , one side of the cutting table 5 is provided with a reinforcing bar fixing mechanism, and the reinforcing bar fixing mechanism includes a slide rail 6, a supporting plate 9, a second drive cylinder 10 and a pressing plate 14, and the slide rail 6 is fixedly installed on the base 1, and the A slide plate 7 is slidably embedded in the slide rail 6, and a translation assembly for driving the slide plate 7 to move horizontally is arranged in the slide rail 6, and a second suppo...

Embodiment 2

[0038] A construction reinforcement cutting device, comprising a base 1, a first support frame 2, a cutting machine 4 and a cutting table 5, the first support frame 2 and the cutting table 5 are fixedly installed on the base 1, the first support frame 2. A first driving cylinder 3 is provided on the top, and a cutting machine 4 is installed at the lower end of the first driving cylinder 3, and the cutting machine 4 is located directly above the cutting table 5;

[0039] One side of the cutting table 5 is provided with a reinforcing bar fixing mechanism, and the reinforcing bar fixing mechanism includes a slide rail 6, a supporting plate 9, a second drive cylinder 10 and a pressing plate 14, and the slide rail 6 is fixedly installed on the base 1, and the A slide plate 7 is slidably embedded in the slide rail 6, and a translation assembly for driving the slide plate 7 to move horizontally is provided in the slide rail 6, and a second support frame 8 and a second drive cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com