Sponge carbon nanotube gas phase collection device and method

A carbon nanotube, collecting device technology, applied in the direction of carbon nanotube, nanocarbon, nanotechnology, etc., to achieve the effect of simple structure and high collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

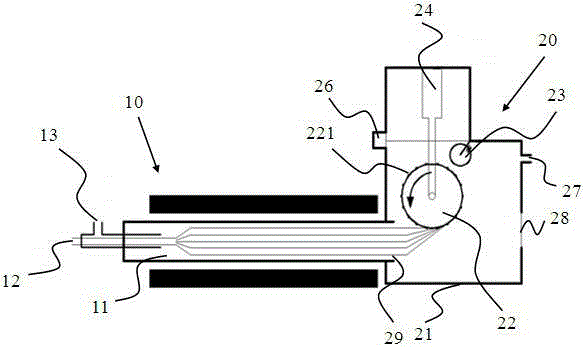

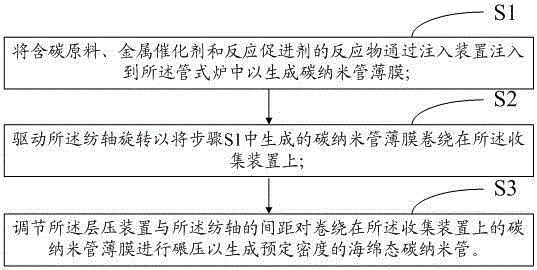

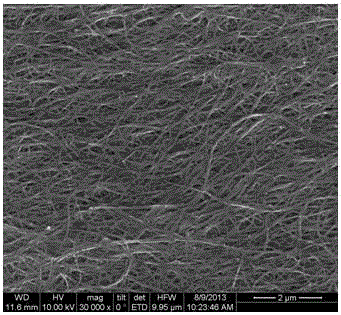

[0034] With ethanol as carbon source, ferrocene as catalyst, hydrogen and argon mixed gas as carrier gas, the heating temperature is 1500°C. exist figure 1 The spongy carbon nanotubes are collected in the device shown, and the collection time is 2 hours. By controlling the distance between the laminating device 23 and the spinning shaft 22, the thickness of the spongy carbon nanotubes is 3 cm, and the obtained density is 18.4 mg / cm 3 , the length is 750cm, and the diameter of the innermost circle is 30cm. It was characterized by scanning electron microscopy and transmission electron microscopy. figure 2 with image 3 , the results show that the sponge carbon nanotubes obtained in this example have a diameter of 2-5 nm, which is a mixture of single-walled and multi-walled carbon nanotubes.

Embodiment 2

[0036] The carbon nanotube preparation process is the same as the first embodiment. in such as figure 1 The spongy carbon nanotubes are collected in the shown device, and the collection time is 4 hours. By controlling the distance between the lamination device 23 and the distance between the spinning shaft 22, the thickness of the spongy carbon nanotubes is 3 cm, and the obtained density is 32.4 mg / cm 3 , the length is 750cm, and the diameter of the innermost circle is 30cm.

Embodiment 3

[0038] The carbon nanotube preparation process is the same as the first embodiment. in such as figure 1 The sponge-state carbon nanotubes are collected in the device shown, and the collection time is 2 hours. By controlling the distance between the laminating device 23 and the spinning shaft 22, the thickness of the sponge-state carbon nanotubes is 1 cm, and the obtained density is 42.3 mg / cm 3 , the length is 750cm, and the diameter of the innermost circle is 30cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com