A Nodulation Analysis Method for Continuous Casting Nozzle

A nodule and nozzle technology, applied in the field of continuous casting nozzle nodule analysis to avoid pouring interruptions or accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

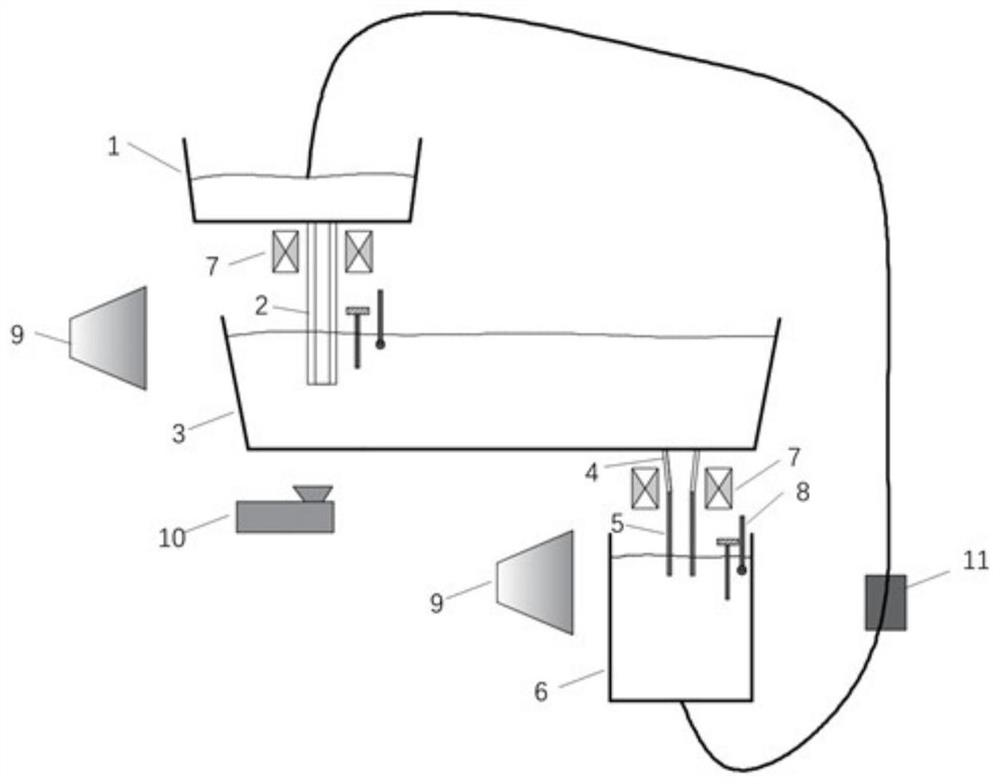

Method used

Image

Examples

Embodiment 1

[0063] Construct the molten steel continuous casting model according to the ratio of 2:1, set a tundish model nozzle in the tundish model of the molten steel continuous casting model, set a mold model and a submerged nozzle in the molten steel continuous casting model . Water was circulated throughout the model to a flow rate of 24.5 L / min through the flow control device. Organic ferromagnetic particles with an average particle size of 100 micrometers are used. The camera uses a long exposure time of 2.0 seconds to record the movement of the organic ferromagnetic particles. And a total of 10 simulation experiments were performed, the electromagnetic field varied from 1 to 10 Tesla, and the step size of the electromagnetic field change in each simulation experiment was 1. The process of loading the electromagnetic field in each simulation experiment can include:

[0064] (1) An electromagnetic field is applied to the nozzle of the ladle model, and the organic ferromagnetic p...

Embodiment 2

[0068] Construct the molten steel continuous casting model according to the ratio of 2.5:1, set a tundish model nozzle in the tundish model of the molten steel continuous casting model, set a mold model and a submerged nozzle in the molten steel continuous casting model . Water was circulated throughout the model to a flow rate of 16.8 L / min through the flow control device. Ferric oxide particles with an average particle size of 20 micrometers are used. The camera uses a long exposure time of 1.0 second to record the movement of the ferric oxide particles. And a total of 20 simulation experiments were performed, the electromagnetic field was changed within 0.1 to 2.0 Tesla, and the step size of the electromagnetic field change in each simulation experiment was 0.1. The process of loading the electromagnetic field in each simulation experiment can include:

[0069] (1) Load an electromagnetic field to the nozzle of the ladle model, so that the ferroferric oxide particles are...

Embodiment 3

[0072] The molten steel continuous casting model is constructed according to the ratio of 4:1. Two tundish model nozzles are set in the tundish model of the molten steel continuous casting model, and two mold models and two molds are set in the molten steel continuous casting model. Submerged spout. Water was circulated throughout the model to a flow rate of 12.3 L / min through the flow control device. Organic ferromagnetic particles with an average particle size of 50 microns are used. The camera uses a long exposure time of 1.0 second to record the movement of the ferric oxide particles. And a total of 9 simulation experiments were performed, the electromagnetic field was changed within 0.05 to 0.5 Tesla, and the step size of the electromagnetic field change in each simulation experiment was 0.05. The process of loading the electromagnetic field in each simulation experiment can include:

[0073] (1) Load an electromagnetic field to the nozzle of the ladle model, so that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com