Double-tire hub assembly assembling equipment

A technology for assembly assembly and tire wheels, which is applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of low assembly efficiency of wheel hub assemblies, achieve the effects of reducing scrap rate, improving production efficiency, and improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

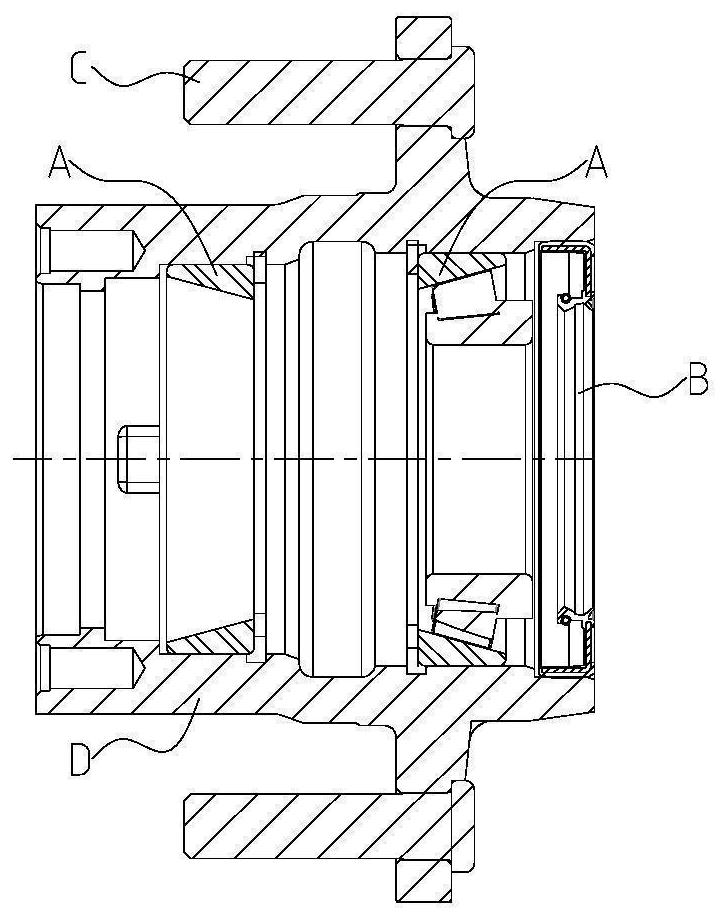

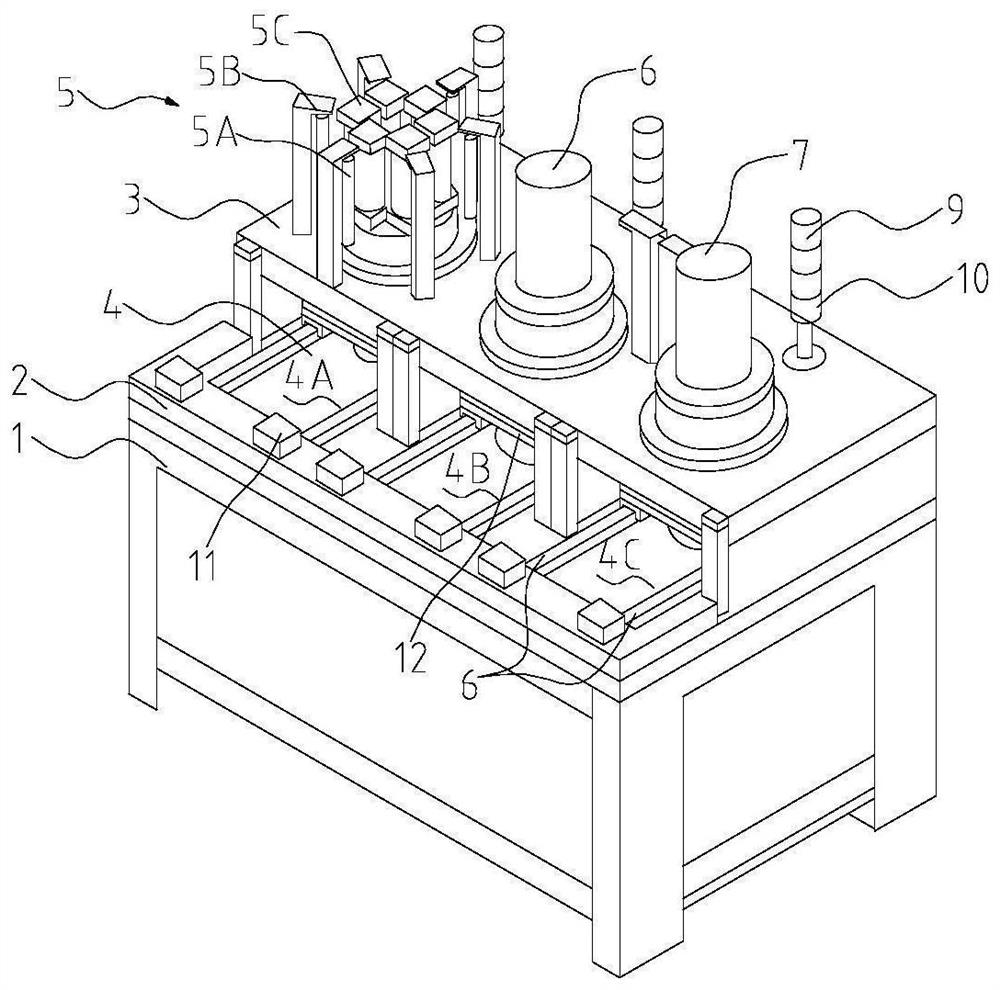

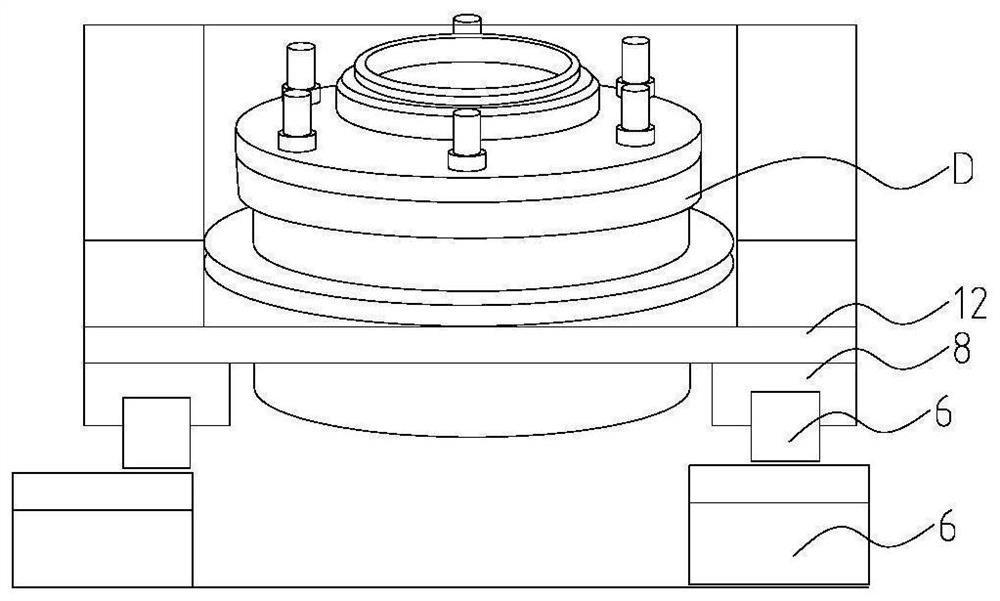

[0021] Further description of the invention is further explained below with reference to the drawings:

[0022] Double tire hub is always assembled equipment, such as figure 2 with image 3 As shown, including the base 1, assembly table 2, and support table 3; the assembly table 2 is supported on the base 1; the support table 3 is supported on the assembly stage 2, and is provided between the support table 3 and the assembly station 2 Revenue space 4; the accommodating space 4 is separated into a first station 4a, a second station 4b, and a third station 4c disposed side by side;

[0023] A bolt press device 5, a bearing pressing device 6, and an oil seal press device 7 are attached to the support table 3;

[0024] The bolt pressure device 5 pairs the first station 4a; the bearing press device 6 pairs the second station 4b; the oil sealing device 7 pairs the third station 4c.

[0025] The dual tire hub is always an assembly apparatus, and the base 1 is used to support the assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com