Building concrete gravel mixing equipment

A kind of mixing equipment and concrete technology, which is applied in the direction of clay preparation equipment, mixing operation control, mixing plant, etc., can solve the problems of reducing mixing effect and efficiency, inconvenient use of mixing equipment, and no grinding and crushing device, etc., to improve mixing effect and efficiency , to ensure the effect of subsequent use, to ensure the effect of use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

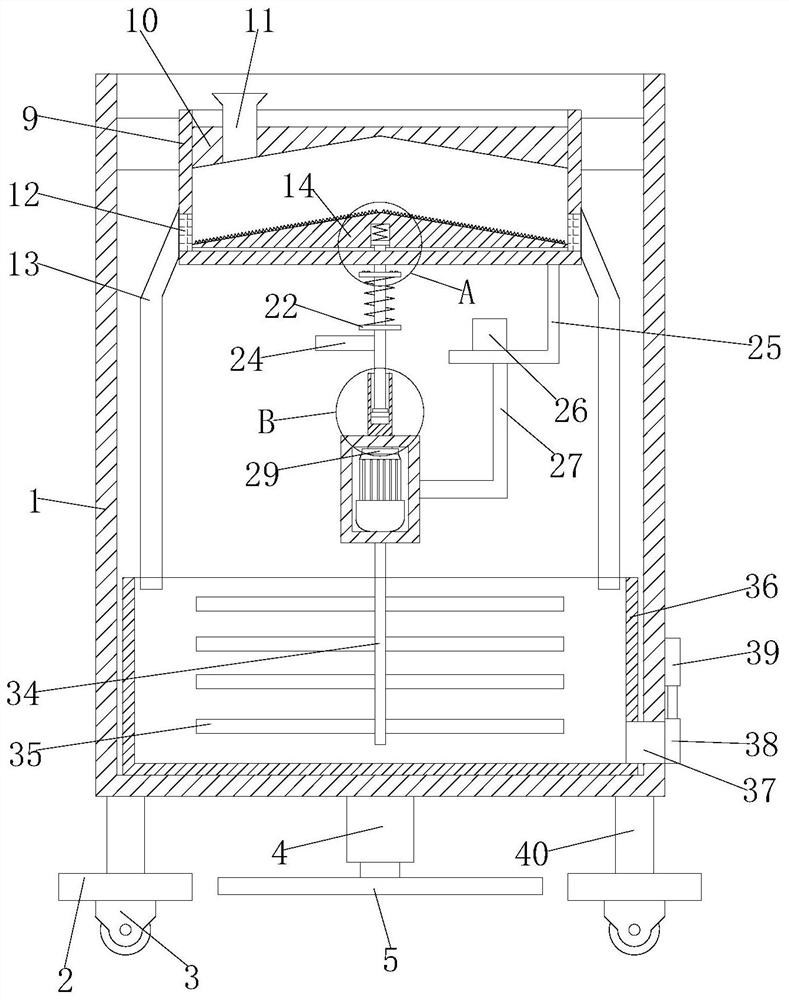

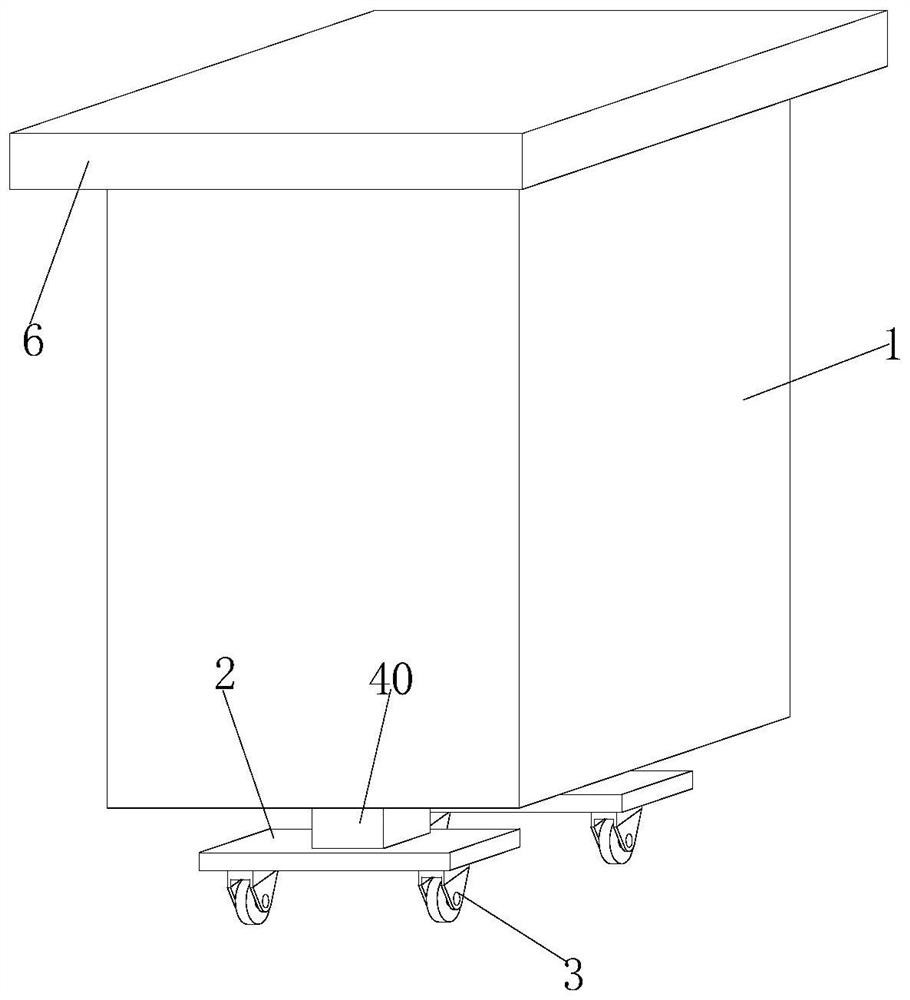

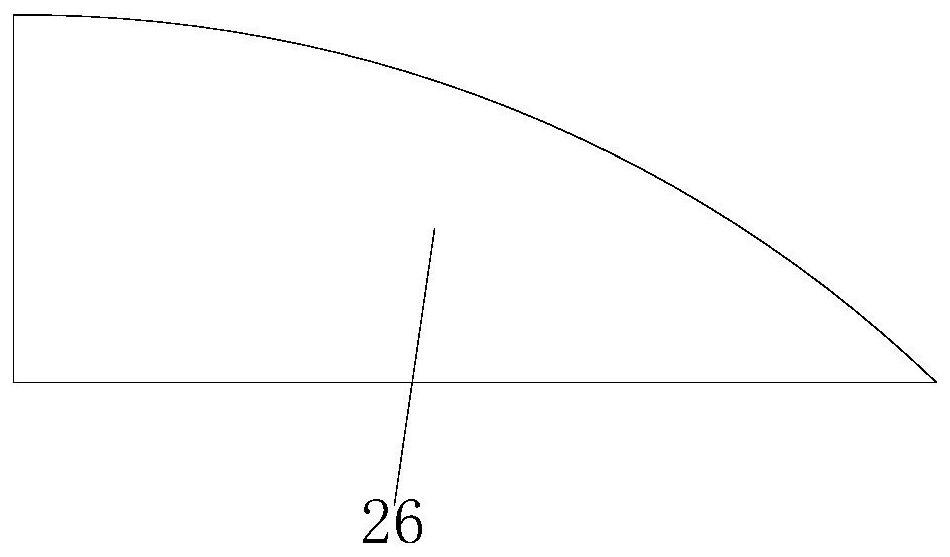

[0026] refer to Figure 1-6 , a construction concrete gravel mixing equipment, comprising a box 1 and a box cover 6, a moving device is installed at the bottom of the box body 1, a support device is fixedly installed at the bottom of the box body 1, and a handle 7 is fixedly installed at the top of the box cover 6, The bottom of the box cover 6 is fixedly equipped with a blocking rod 8, and the inside of the box body 1 is fixedly installed with a grinding box 9, and an upper shutter 10 is fixedly installed in the grinding box 9, and a feed pipe 11 is fixedly installed on the upper shutter 10, and the grinding box 9 is fixedly installed with filter screen 12, on the grinding box 9 is fixedly installed with several material guide pipes 13, the bottom of grinding box 9 is fixedly equipped with installation rod 25, and the bottom of installation rod 25 is fixedly installed with bottom rod 27, bottom rod 27 Mounting box 28 is fixedly installed on the top, and biaxial motor 29 is fi...

Embodiment 2

[0036] refer to Figure 1-6 , a construction concrete gravel mixing equipment, comprising a box 1 and a box cover 6, a moving device is installed at the bottom of the box body 1, a support device is fixedly installed at the bottom of the box body 1, and a handle 7 is fixedly installed at the top of the box cover 6, The bottom of the box cover 6 is fixedly equipped with a blocking rod 8, and the inside of the box body 1 is fixedly installed with a grinding box 9, and an upper shutter 10 is fixedly installed in the grinding box 9, and a feed pipe 11 is fixedly installed on the upper shutter 10, and the grinding box 9 is fixedly installed with filter screen 12, on the grinding box 9 is fixedly installed with several material guide pipes 13, the bottom of grinding box 9 is fixedly equipped with installation rod 25, and the bottom of installation rod 25 is fixedly installed with bottom rod 27, bottom rod 27 Mounting box 28 is fixedly installed on the top, and biaxial motor 29 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com