Section heat shrinkage film end sealing method

A heat-shrinkable film and profile technology, applied in the direction of external support, wrapping paper shrinkage, packaging sealing/fastening, etc., can solve the problems of poor wrapping effect of heat-shrinkable film, bursting of heat-shrinkable film profiles, poor sealing effect, etc. Achieve good packaging effect, avoid pulling deformation, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

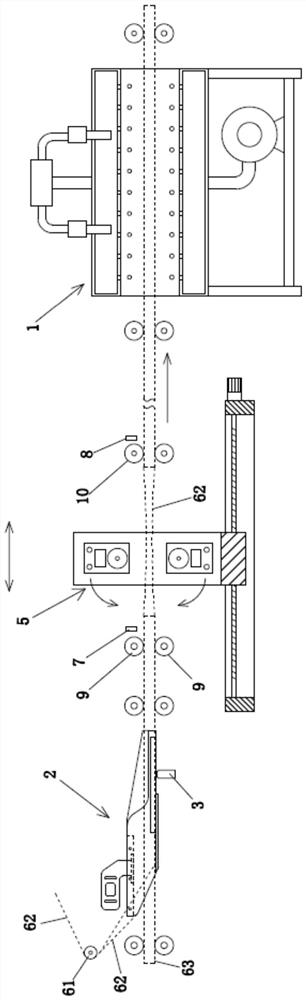

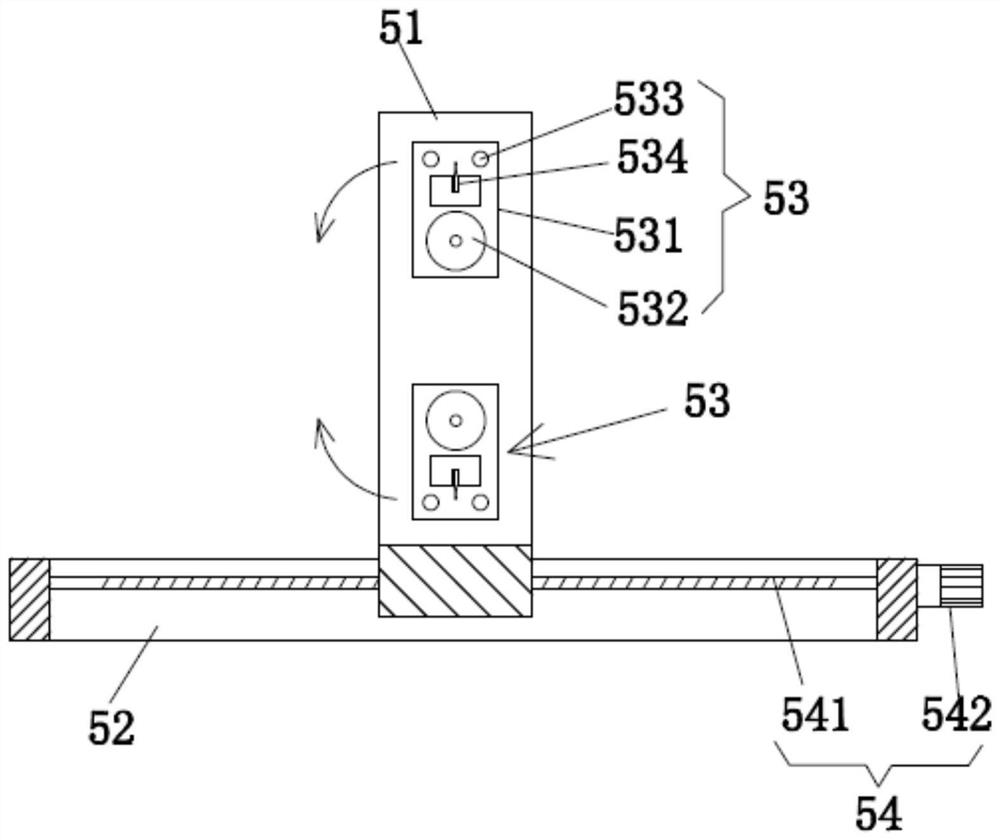

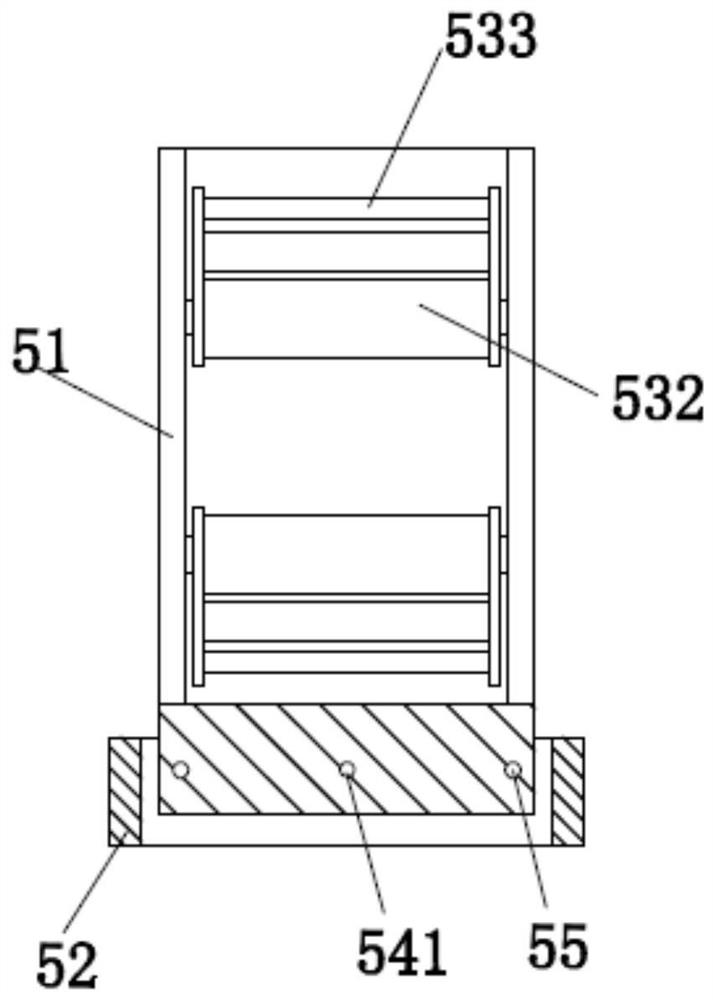

[0032] The specific embodiment of the present invention is as Figure 1 to Figure 11 As shown, a profile heat shrinkable film end sealing device includes a sealing mechanism, the sealing mechanism is arranged on the sealing device support 51, and the front and rear sides of the sealing mechanism are respectively provided with a first profile conveying mechanism 9 and a second profile conveying mechanism 10. The sealing device support 51 is connected with a support drive mechanism 54 that makes it move back and forth along the profile conveying direction.

[0033] The sealing mechanism includes two sealing structures 53 respectively arranged on the upper and lower sides of the profile conveying path. Each sealing structure 53 includes two heating elements 533 that can approach and move away from the heat shrinkable film on the profile. In this embodiment, the heating elements 533 are electric heating tubes. The two heating elements 533 on the two sealing structures 53 corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com