Cutting machine stable in material conveying

A cutting machine and stable technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as difficult to clean and affect the service life of conveyor belts, and achieve the effect of prolonging service life and improving operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are simplified diagrams and are used to illustrate the

[0066] The basic structure of the invention, so it only shows the constructions relevant to the invention.

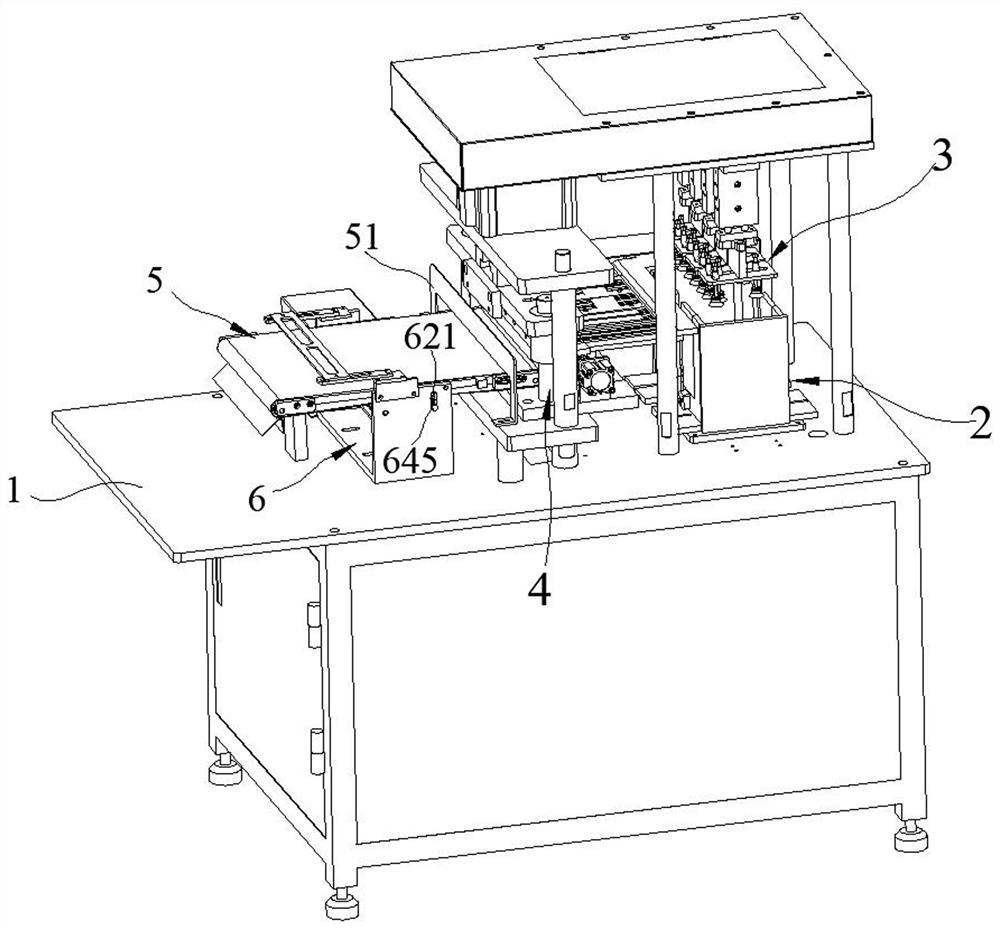

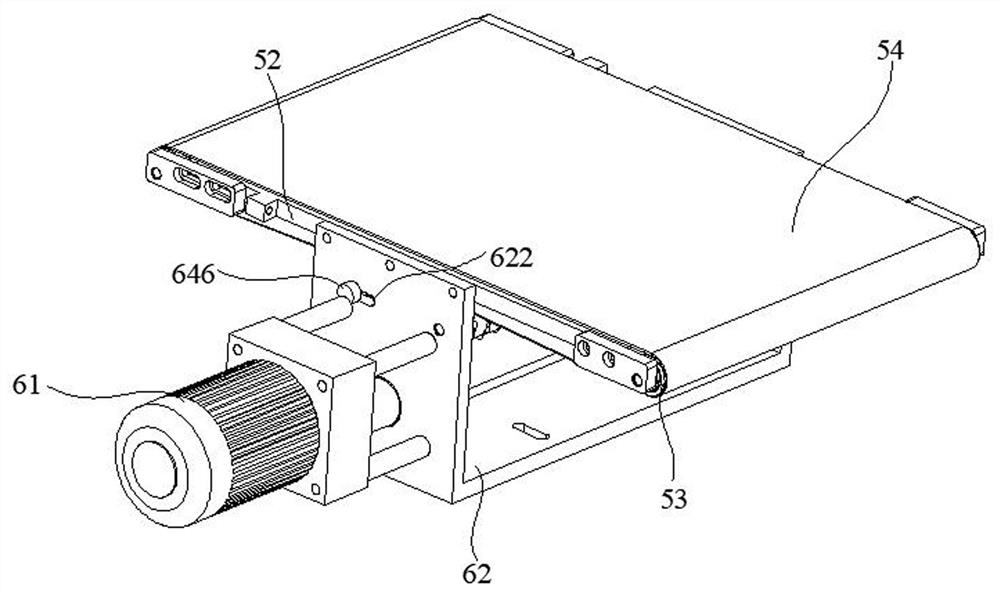

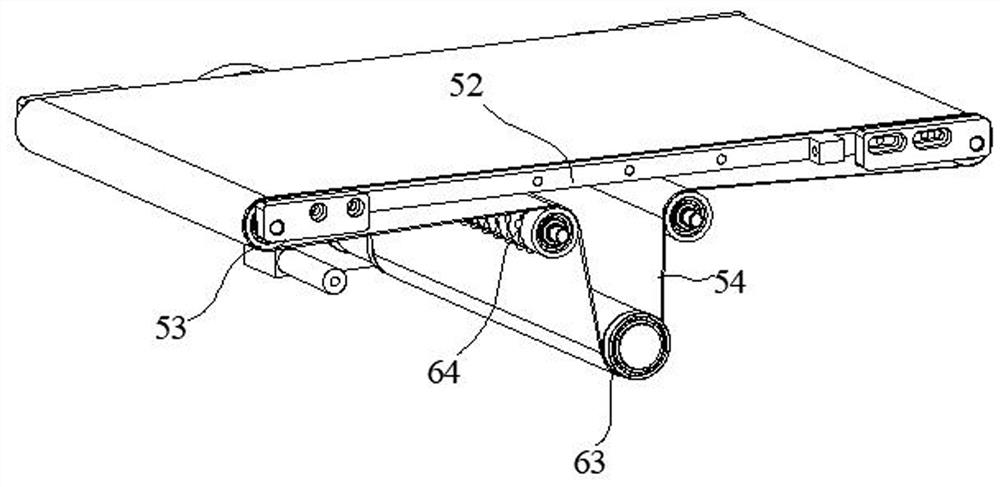

[0067] Such as Figure 1 to Figure 15 As shown, a cutting machine with stable feeding of the present invention includes: a working platform 1, a conveyor belt 5 and a driving part 6, and the conveyor belt 5 and the driving part 6 are fixed on the working platform 1, The working platform 1, as the main support and platform of the cutting machine of the present invention, provides space and support for operation; the conveyor belt 5 is suitable for transporting plates, and the driving part 6 is arranged below the conveyor belt 5, The driving part 6 can drive the conveyer belt 5 to move circularly; the driving part 6 includes: a driving motor 61, a first fixed frame 62, a driving roller 63 and tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com