Method for preparing cement-based wet-mixed mortar aggregate by modification of phosphogypsum and mortar

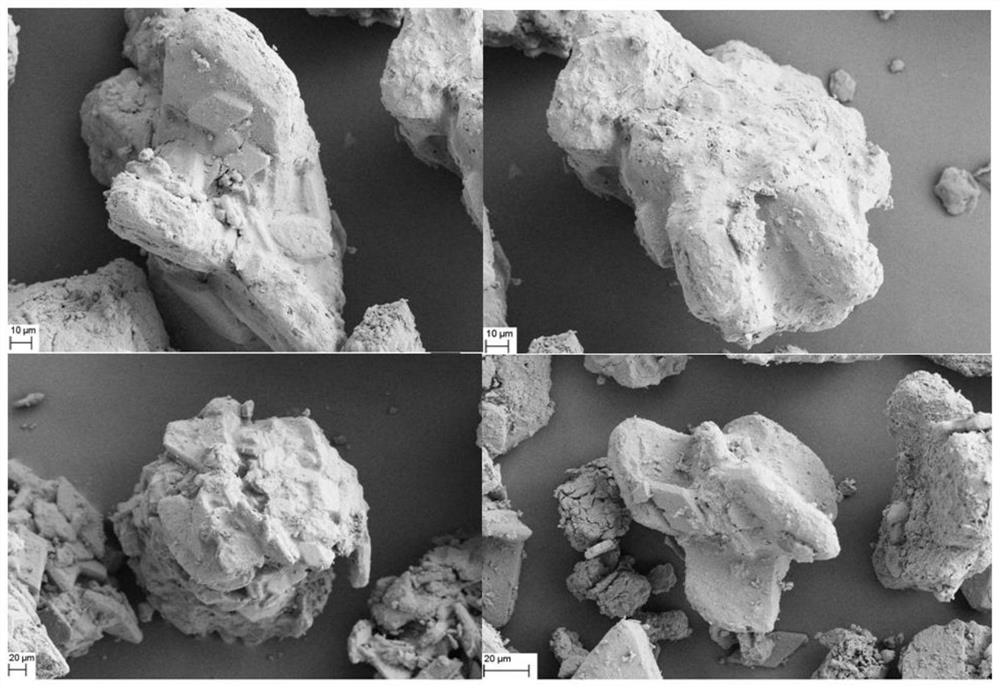

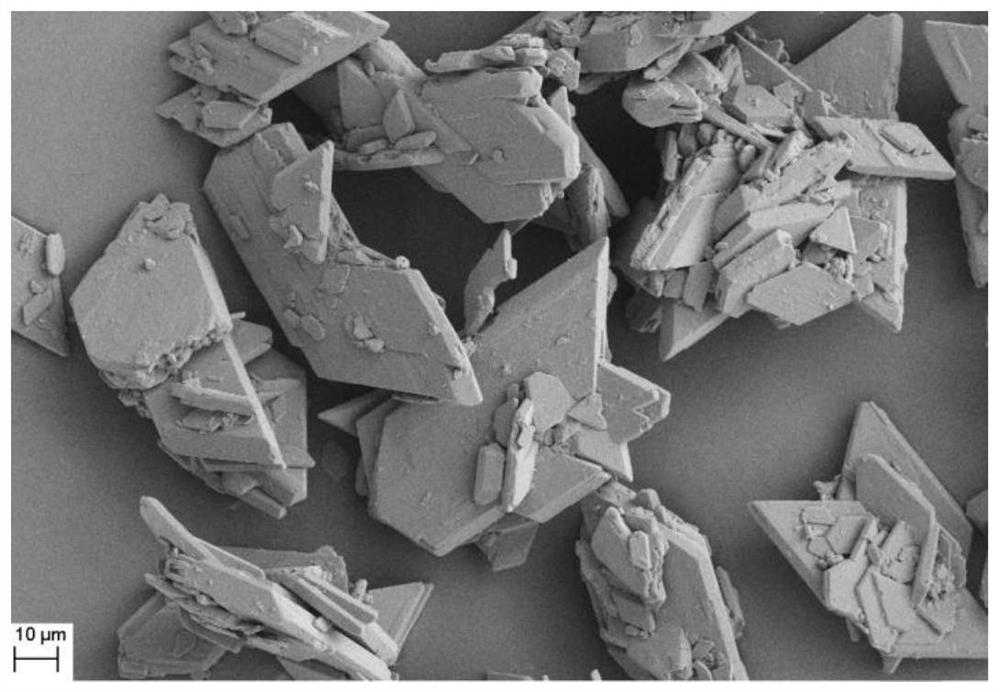

A technology of wet-mixed mortar and phosphogypsum, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of mortar cracking, easy damage of particles, incomplete wrapping, etc., to avoid negative effects, slow down The effect of reducing pollution pressure and avoiding expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

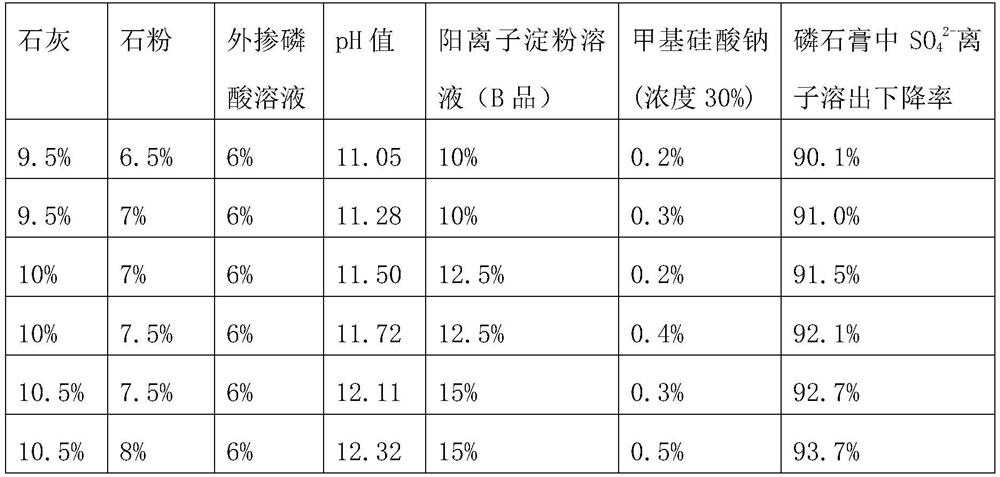

[0033] The method for preparing cement-based wet-mixed mortar aggregate by modification of phosphogypsum, the steps are as follows:

[0034] The first step: take phosphogypsum with a moisture content of less than 5%, add 9% lime, 7% stone powder and 5.5% phosphoric acid solution of the mass of phosphogypsum, stir and neutralize, and age for 2 days to obtain product A;

[0035] The second step: take water, add cationic starch of 4% of the water mass, stir and mix evenly, heat to 90 ° C, stop heating after gelatinization for 2 hours, and place it to cool to obtain product B;

[0036] The third step: take product A, first add 12% of the mass of product A, product B, mix and stir evenly, bake at 50°C for 30 minutes, and then add 13% of product B of product A for the second mixing and stirring, After stirring evenly, bake again at 50°C for 30min to obtain C product;

[0037] Step 4: Spray C product with 0.5% sodium methyl silicate water repellent of the quality of C product during...

Embodiment 2

[0039] The method for preparing cement-based wet-mixed mortar aggregate by modification of phosphogypsum, the steps are as follows:

[0040] The first step: take phosphogypsum with a moisture content of less than 5%, add 8% lime, 6% stone powder and 5% phosphoric acid solution of the mass of phosphogypsum, stir and neutralize, and age for 1 day to obtain product A;

[0041] The second step: take water, add 2% cationic starch of the water mass, stir and mix evenly, heat to 80 ° C, stop heating after gelatinization for 3 hours, and place it to cool to obtain product B;

[0042]Step 3: Take product A, first add 10% of the mass of product A and product B, mix and stir evenly, bake at 40°C for 40 minutes, and then add 10% of the mass of product A to product B for the second mixing and stirring, After stirring evenly, bake again at 40°C for 40min to obtain C product;

[0043] The fourth step: spray the C product with 0.1% sodium methyl silicate waterproofing agent of the quality of...

Embodiment 3

[0045] The method for preparing cement-based wet-mixed mortar aggregate by modification of phosphogypsum, the steps are as follows:

[0046] The first step: take phosphogypsum with a moisture content of less than 5%, add 8.5% lime, 6.5% stone powder and 5.3% phosphoric acid solution of the mass of phosphogypsum, stir and neutralize, and age for 1 day to obtain product A;

[0047] The second step: take water, add 6% cationic starch of the water mass, stir and mix evenly, heat to 100 ° C, stop heating after gelatinization for 2 hours, and place it to cool to obtain product B;

[0048] Step 3: Take product A, first add 15% of the mass of product A and product B, mix and stir evenly, bake at 60°C for 20 minutes, then add 15% of product B by the mass of product A for the second mixing and stirring, After stirring evenly, bake again at 60°C for 20min to obtain C product;

[0049] The fourth step: spray the C product with 0.8% potassium methyl silicate waterproofing agent in the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com