Laser galvanometer scanning system

A laser vibrating mirror and scanning system technology, applied in optics, optical components, instruments, etc., can solve problems such as corrosion of electronic components, easy adhesion of field mirror surface by external dust, increased technical cost, etc., to reduce processing time and improve processing Efficiency, the effect of reducing technology costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

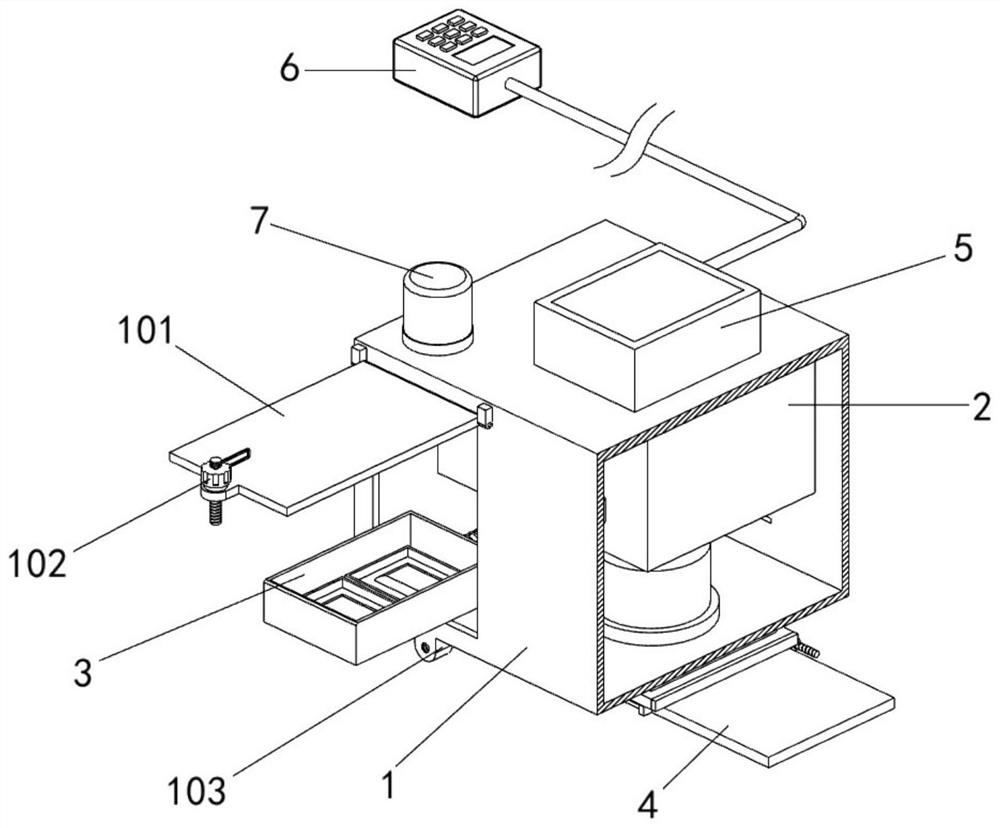

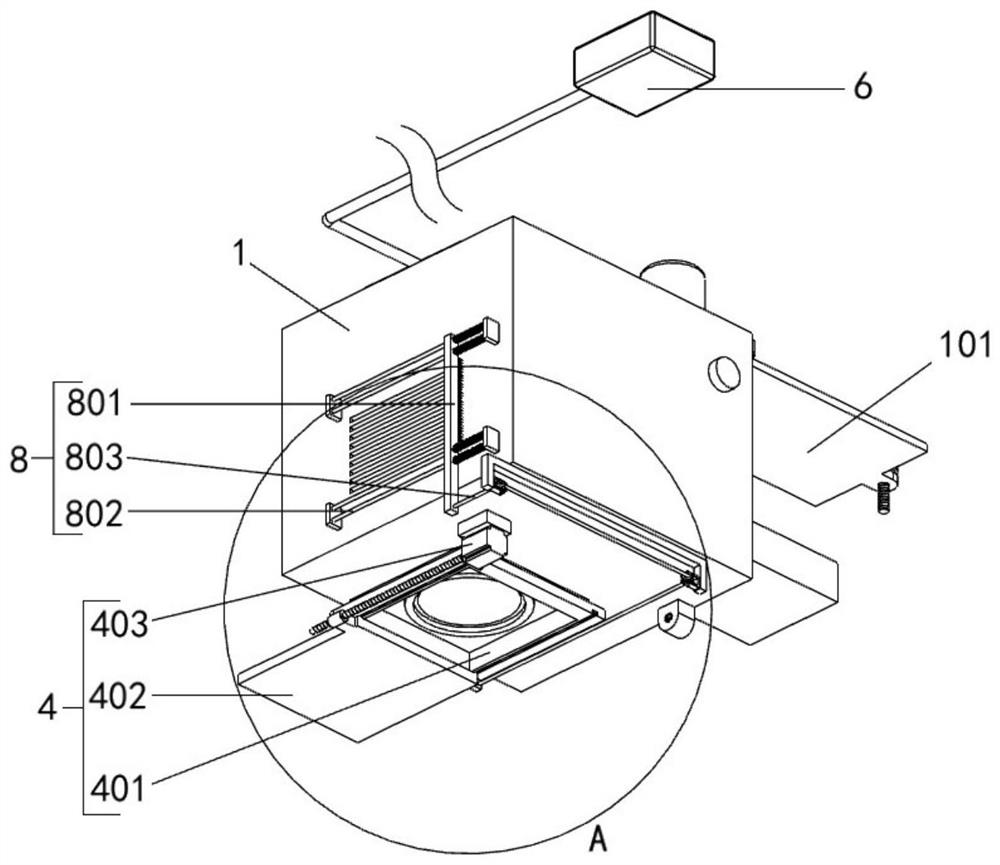

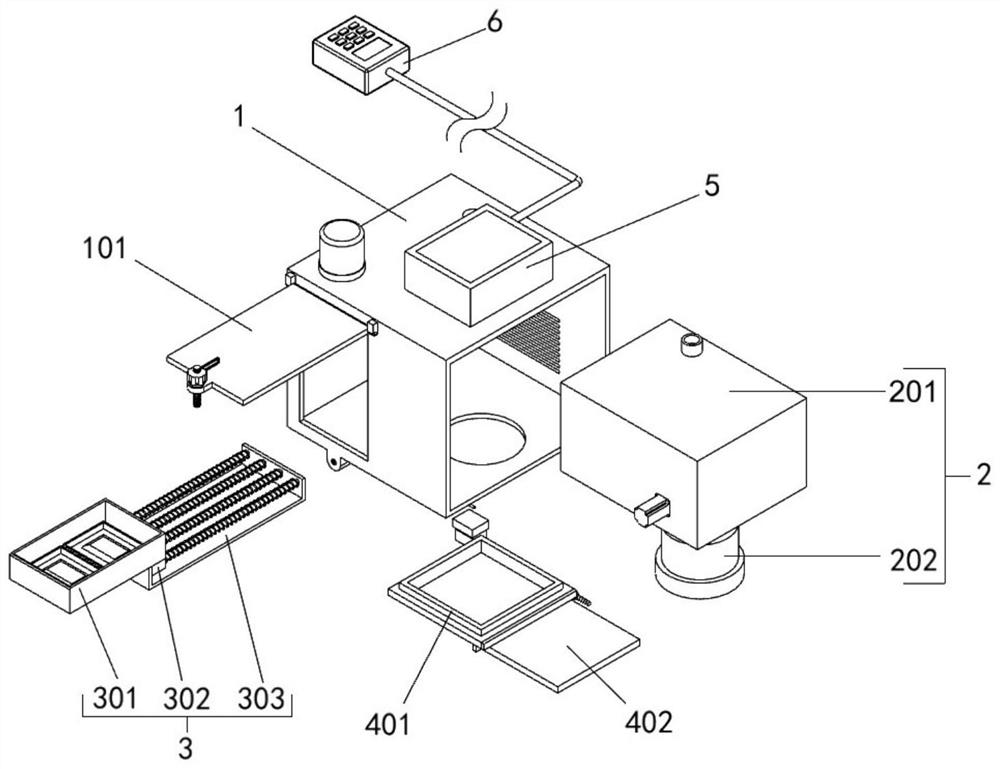

[0035] Append figure 1 Adherent Figure 8 Down:

[0036] The present invention provides a laser spray mirror scanning system, including: housing 1; inner portion of the housing 1 is provided with a spray mirror support mechanism 2, and the upper left end of the inner front side of the housing 1 is opened; the housing 1 includes a sealing plate 101 , The hand-tissue bolt 102, the connection nut 103 and the temperature and humidity sensor 104, the front end surface inspection opening of the housing 1 is rotated by the rotating shaft 101, and the lower end of the sealing plate 101 slides through the hand-rolled bolt 102; the connection nut 103 is fixed The front side of the upper end surface of the housing 1, and the connection nut 103 is threaded with the hand-rolled bolt 102 stud, the upper left side of the housing 1 is attached to the upper left side surface of the housing 1, and the temperature and humidity sensor 104 is mounted, and the temperature and humidity sensor 104 passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com