Cacao pulp juice dried powder, food product in which same is blended, and methods for producing these

A technology of drying powder and manufacturing method, applied in the directions of cocoa, food science, application, etc., can solve the problems of processing cocoa juice into powder and compounding that have not yet been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

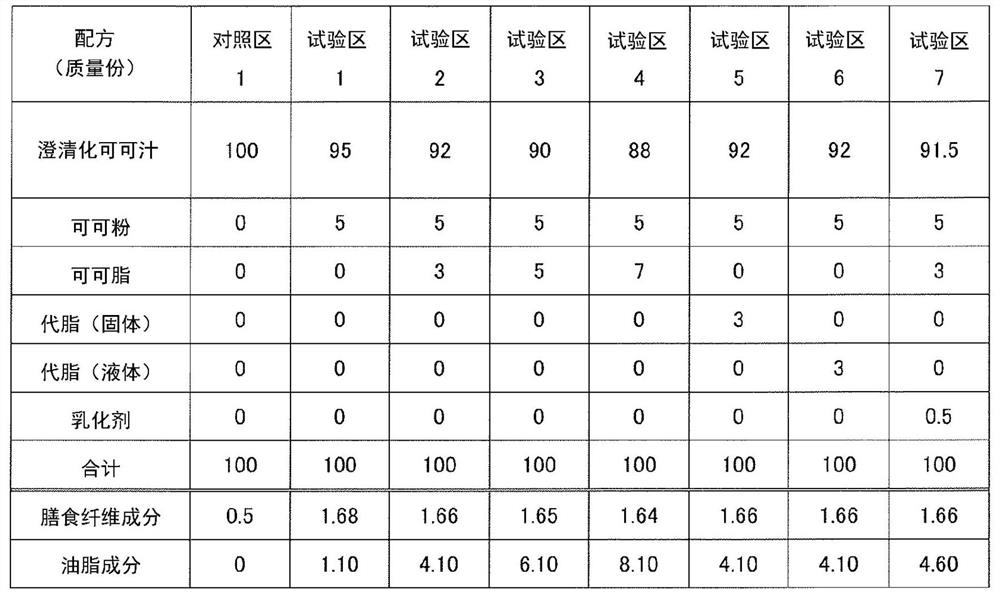

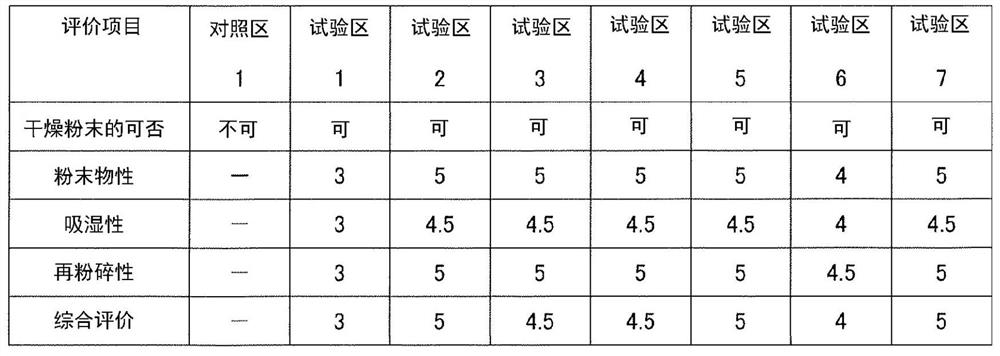

[0060] Example 1: Manufacture of Cocoa Juice Powder

[0061] The cocoa juice base was prepared using the raw materials described in Table 1. Specifically, raw materials other than clarified cocoa juice among the raw materials described in Table 1 were mixed with a mixer. Clarified cocoa juice was added to the resulting mixture and mixed to finally reach an emulsified state (O / W), thereby preparing a cocoa juice base. The prepared cocoa juice bases are respectively added into transparent bags, frozen in a refrigerator and left to stand for one night, and then vacuum freeze-dried by a freeze dryer to obtain a freeze-dried powder. Vacuum freeze-drying was carried out at 40° C. (shelf temperature) for 25 hours.

[0062] Clarified cocoa juice is prepared by removing fiber components from cocoa juice using a back filtration process. Clarified cocoa juice had a Brix value of 19.4. In addition, the clarified cocoa juice contains 0.5% by mass of dietary fiber (measured by the enz...

Embodiment 2

[0079] Example 2: Production of chocolate blended with cocoa juice powder

[0080] Fatty confectionary (chocolate) was produced using the cocoa juice powder produced in Example 1. First, chocolate bases were prepared by a conventional method using the raw materials described in Table 3. Next, after filling the obtained chocolate blank into a mold, it is cooled and solidified, and demolded to obtain a fat-based dessert (chocolate).

[0081] [table 3]

[0082] Table 3: Ingredients for chocolate

[0083] Raw materials (parts by mass) Dark Chocolate Type 1 Dark chocolate type 2 milk chocolate type Dry powder (embodiment 1 · test area 2) 37 37 37 cocoa mass 37 36.5 28.5 Coco fat 26 26 26 whole milk powder - - 8 Emulsifier (lecithin) - 0.5 0.5 total 100 100 100

[0084] The obtained oil-based confectionery (chocolate) not only had good melting in the mouth, texture, and high-quality cocoa taste, but also had ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com