Environment-friendly livestock breeding equipment and working method thereof

An environmental protection and equipment technology, applied in the field of animal husbandry, can solve the problems of electrical components loss, poor safety, waste of water resources, etc., to avoid accidents, avoid unnecessary losses, and save water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

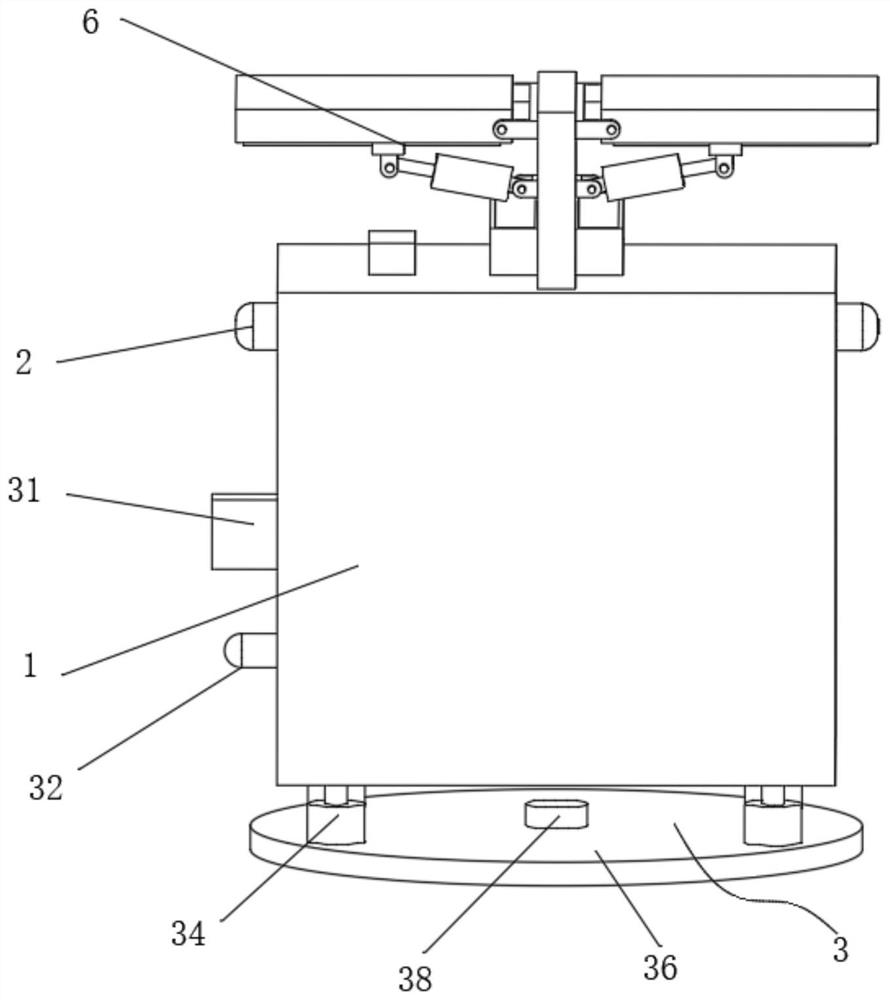

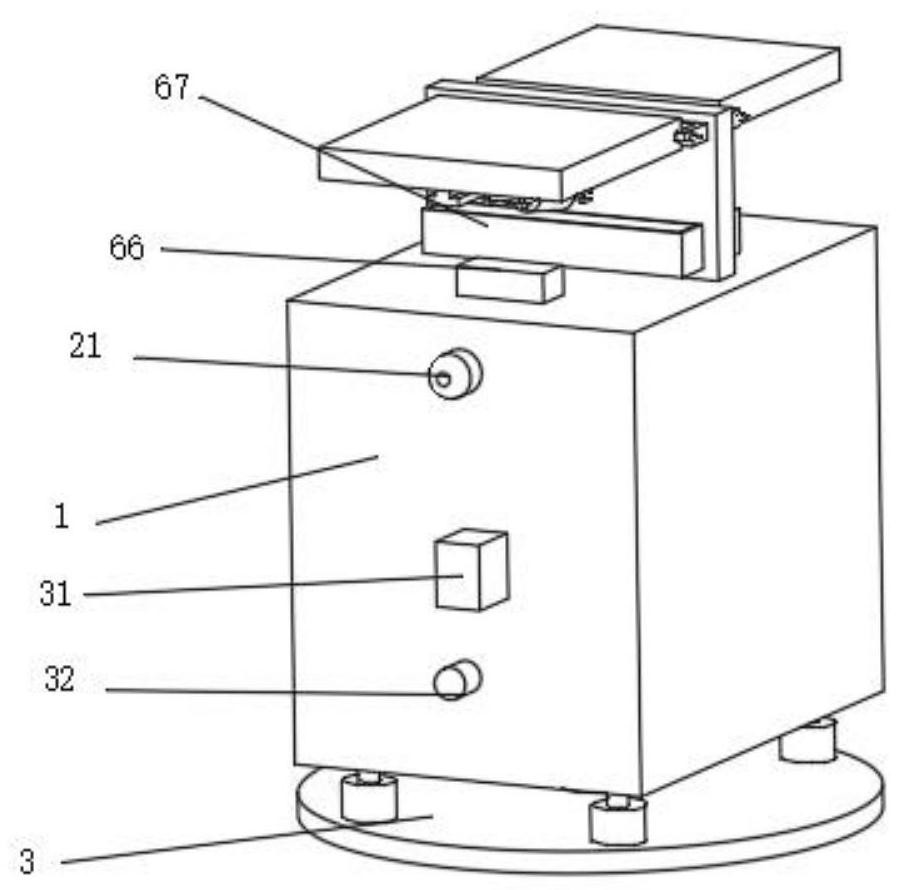

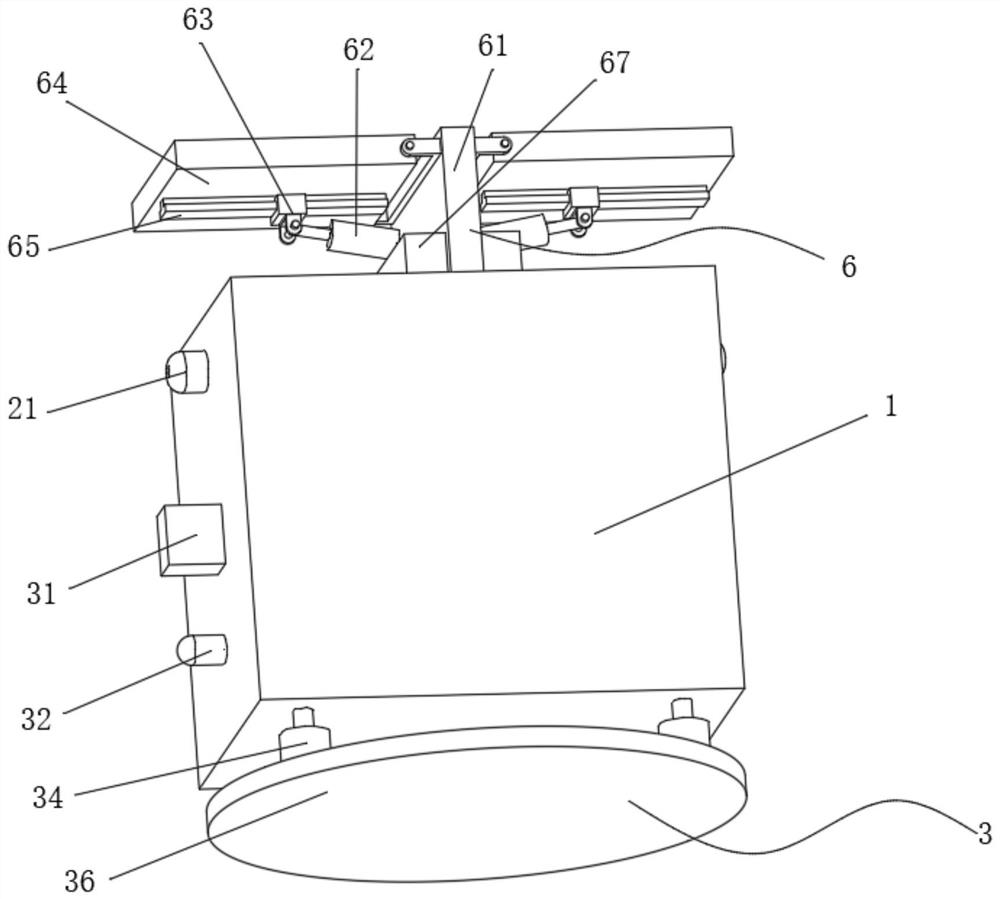

[0032]As an embodiment of the present invention, the cleaning structure 2 includes a first motor 21, a first slider 22, a first slide rail 23, a first filament rod 24, a cleaning head 25, a first cylinder 26, a scraper 27, and a protection. On the column 28, the first sliding rail 23 is fixed to the end side wall of the chamber cavity of the breeding chamber 1, and the first sliding rail 23 is sided with two first sliding blocks 22, and there are two sorrels on the top outer wall of the breeding chamber 1. A motor 21, the first motor 21 is fitted with a first wire rod 24, and the first slider 22 has a screw hole, and the other end of the first thread rod 24 is inserted within the screw hole. The bottom side of the block 22 is fixed, and the first cylinder 26 is fixed, respectively, and the first cylinder 26 is attached to the squeegee 27, and one side of the blade 27 is fixedly cleaned, and the other side of the blade 27 is fixedly protected. 28 The inside of the breeding chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com