Electric planer and wood planing method thereof

A technology of electric planer and planer, which is applied in the direction of manual planer, wood processing equipment, and processing machines for manufacturing flat surfaces, etc., which can solve the problems of easy insertion of blades, lack of guide mechanism, and damage to bamboo and wood structures, etc., so as to achieve convenient replacement and avoid The effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

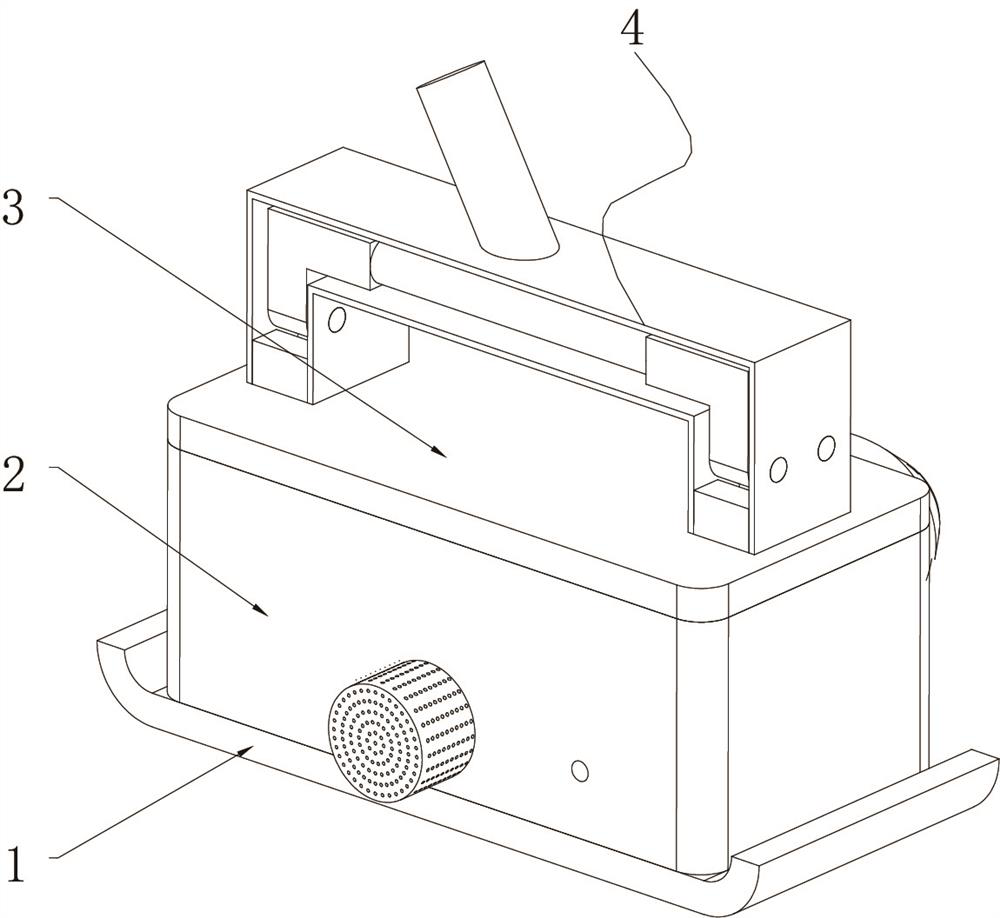

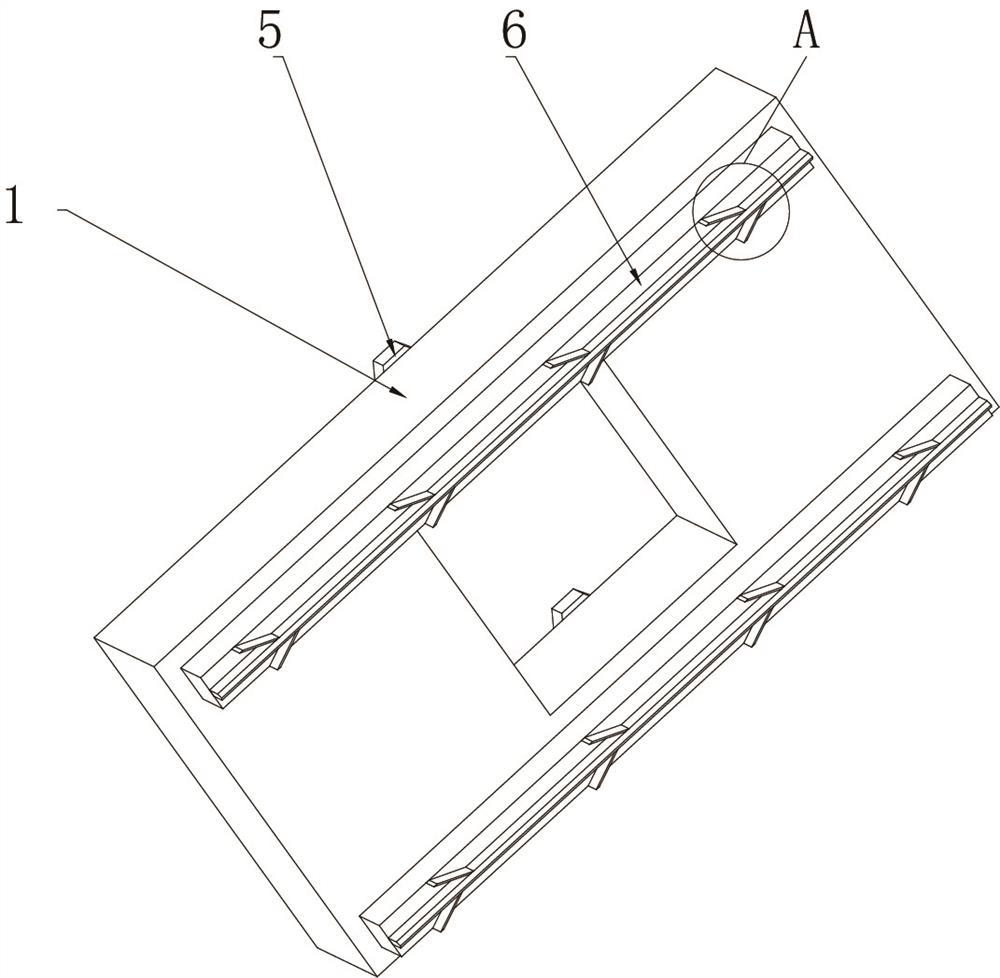

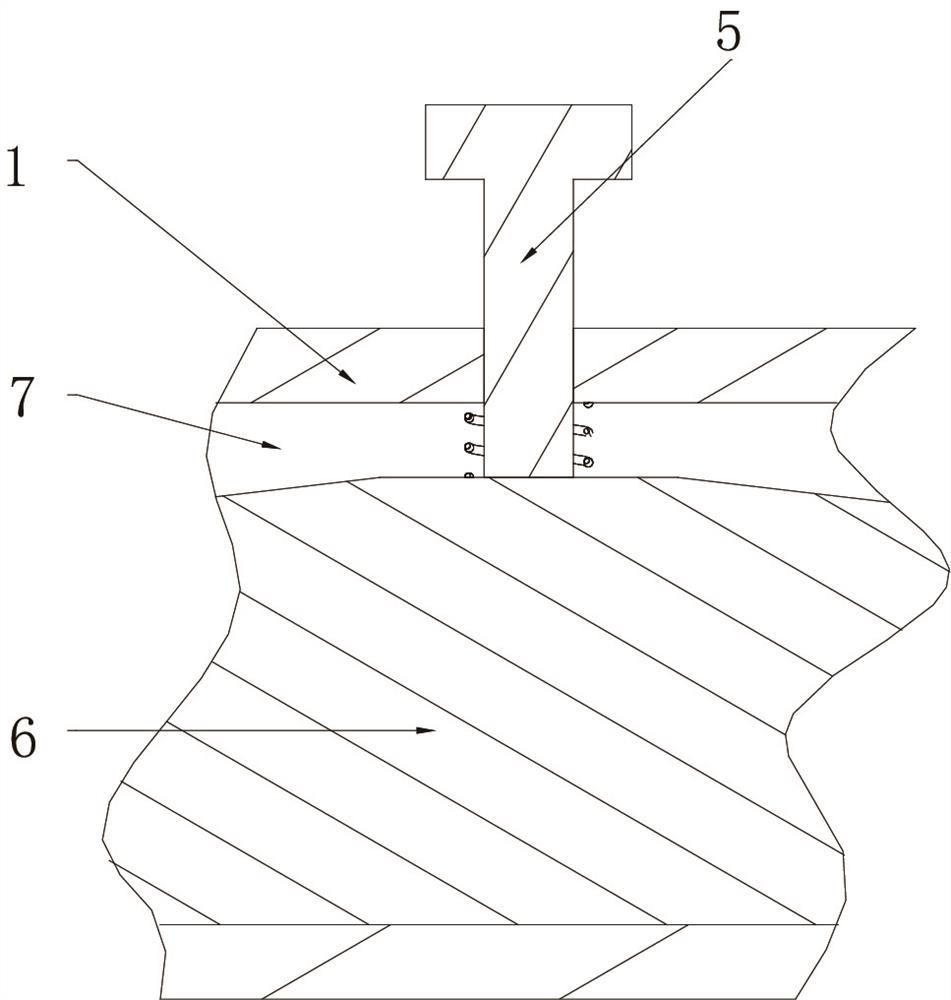

[0041] An electric planer, such as Figure 1-4As shown, it includes a base 1, the top of the base 1 is fixed with a housing 2 by bolts, the top of the housing 2 is fixed with a top cover 3 by bolts, the bottom of the base 1 is provided with a guide assembly, and the guide assembly includes Two rectangular sliders 6, the two rectangular sliders 6 are slidingly connected with the base 1 through the chute 7 provided in the base 1, the top of the base 1 is connected with the adjustment bolt 5 through the bearing rotation, the adjustment bolt 5 The bottom of the rectangular slider 6 is threadedly connected, and the outer wall of the bottom circumference of the adjusting bolt 5 is covered with an anti-loosening spring. The outer wall of the bottom of the rectangular slider 6 is welded with a guide blade 9, and the two guide blades 9 The sides are welded with uniform and staggered flanks 8, the height of which is 1-2 mm lower than the guide blade 9; The board 9 can be embedded in th...

Embodiment 2

[0049] an electric planer, such as figure 1 , 9 As shown, in order to solve the problem of operation mode; this embodiment makes the following improvements on the basis of embodiment 1: the top outer wall of the top cover 3 is provided with a handle assembly 4 for holding, and the handle assembly 4 includes a bracket 35 and a rubber Column handle 2 40, the cross section of the bracket 35 is "I" shape, the rubber column handle 2 40 is fixed on the top outer wall of the bracket 35 by bolts, and the inner walls on both sides of the bracket 35 are connected by the hinge shaft 36 Rotationally connected with two symmetrical rotating ears 38, the outer walls of the opposite side of the two rotating ears 38 are fixed with the same rubber column handle 1 39 by bolts, and the inner side walls of the bottom of the bracket 35 are fixed to a limited position by bolts. Block 37.

[0050] When this embodiment is in use, because in embodiment 1, the single-pass planing depth can be adjusted...

Embodiment 3

[0052] A method of planing wood with an electric planer, such as Figure 1-9 As shown, the specific steps are as follows:

[0053] S1: Firstly, according to the demand for planing wood, the depth of single-way planing wood is controlled by adjusting the bolt 5;

[0054] S2: Start the device, make the first attempt to plan wood, and sense the movement resistance;

[0055] S3: Select one-handed operation and two-handed operation mode according to the perceived movement resistance;

[0056] S4: put the empty collection bag 25 on the inner threaded ring 28 through the elastic band 27, and plan wood work;

[0057] S5: When the collection bag 25 is full, take it off, pour out the sawdust, and continue to load it on the internal thread ring 28.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com