A kind of preparation method of nitride powder

A technology of nitrides and powders, which is applied in the field of preparation of nitrides powders, can solve the problems of difficulty in the reaction between nitrogen and aluminum elements, hindering the penetration of nitrogen into the interface, and high nitriding temperature, so as to shorten the nitriding reaction time and improve the production The effect of high speed and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) 10g of aluminum sol, 250g of anionic water-based polyurethane, mixed evenly to form a homogeneous mixture. Put the mixed solution in an oven to heat and cure, the curing temperature is 250°C. After solidification, the mixture is pulverized by ball milling to obtain a uniform mixed powder, which is placed in a high-temperature graphite furnace. Flowing nitrogen gas is introduced into the high-temperature graphite furnace to exhaust the air in the furnace, and the nitrogen flow rate is 4L / min. The high-temperature graphite furnace is heated up from room temperature to 1600°C in 5.5 hours, and kept at 1600°C for 4 hours.

[0045] (2) The nitriding product is decarburized at 600° C. in the air environment, and the decarburization time is 2 hours.

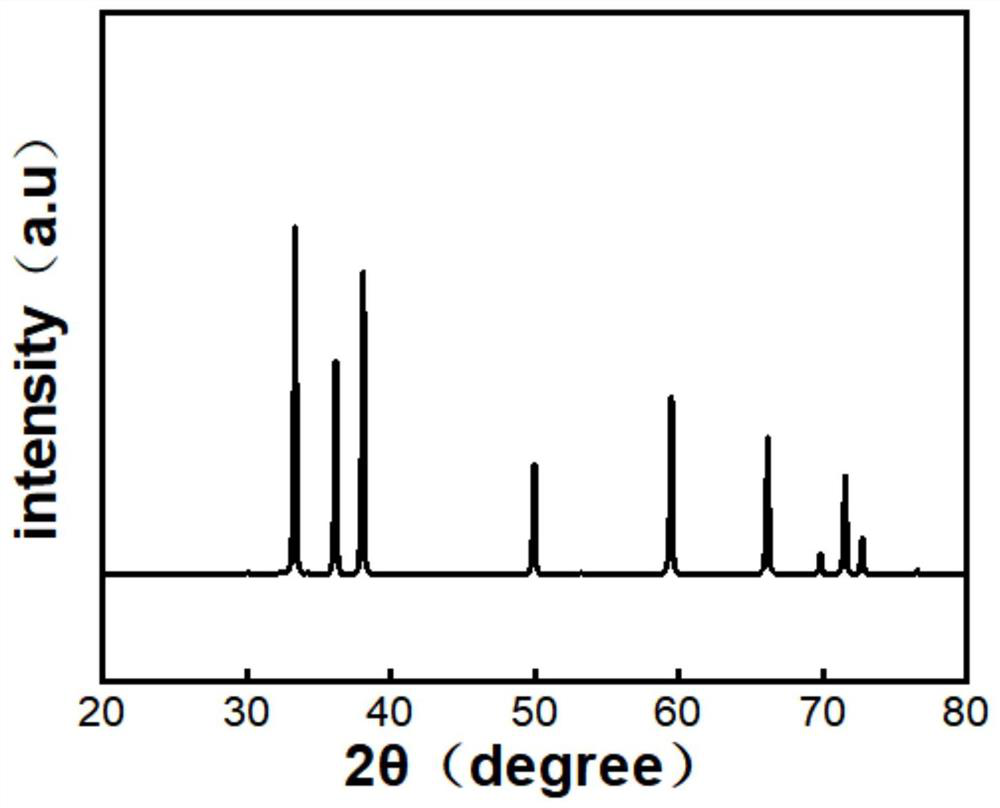

[0046] The product aluminum nitride powder is analyzed by XRD, and the product has no other phase diffraction peaks, and is a pure aluminum nitride product. The oxygen content of aluminum nitride is 0.6% as tested by nitro...

Embodiment 2

[0048] (1) 10g of aluminum sol, 200g of anionic water-based polyurethane, mixed evenly to form a homogeneous mixture. Put the mixed solution in an oven to heat and cure, the curing temperature is 200°C. After solidification, the mixture is pulverized by ball milling to obtain a uniform mixed powder, which is placed in a high-temperature graphite furnace. Flowing nitrogen gas is introduced into the high-temperature graphite furnace to exhaust the air in the furnace, and the nitrogen flow rate is 4L / min. The high-temperature graphite furnace is heated up from room temperature to 1600°C in 5.5 hours, and kept at 1600°C for 3 hours.

[0049] (2) The nitriding product is decarburized at 600° C. in the air environment, and the decarburization time is 2 hours.

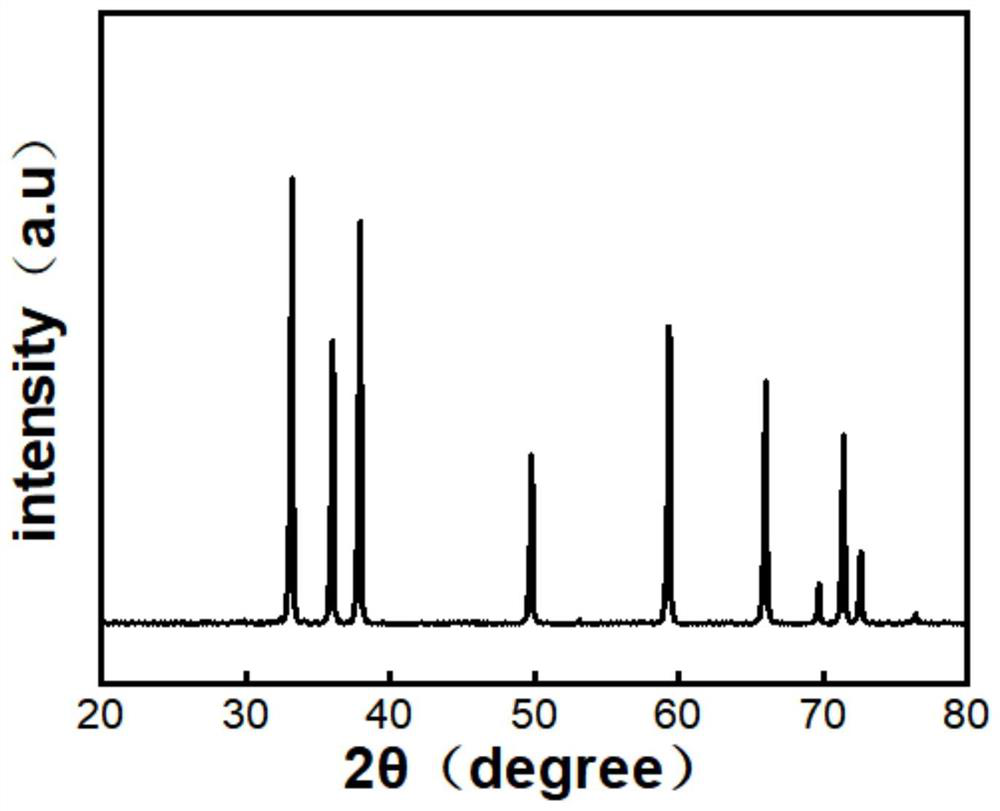

[0050] The product aluminum nitride powder is analyzed by XRD, and the product has no other phase diffraction peaks, and is a pure aluminum nitride product. The oxygen content in aluminum nitride is 0.7% as tested by a nit...

Embodiment 3

[0052] (1) 10g of aluminum sol and 180g of anionic water-based polyurethane were uniformly mixed to form a homogeneous mixture. Put the mixed solution in an oven to heat and cure, the curing temperature is 200°C. After solidification, the mixture is pulverized by ball milling to obtain a uniform mixed powder, which is placed in a high-temperature graphite furnace. Flowing nitrogen gas is introduced into the high-temperature graphite furnace to exhaust the air in the furnace, and the nitrogen flow rate is 3L / min. The high-temperature graphite furnace is heated up from room temperature to 1500°C in 5 hours, and kept at 1500°C for 2 hours.

[0053] (2) The nitriding product is decarburized at 600° C. in the air environment, and the decarburization time is 2 hours.

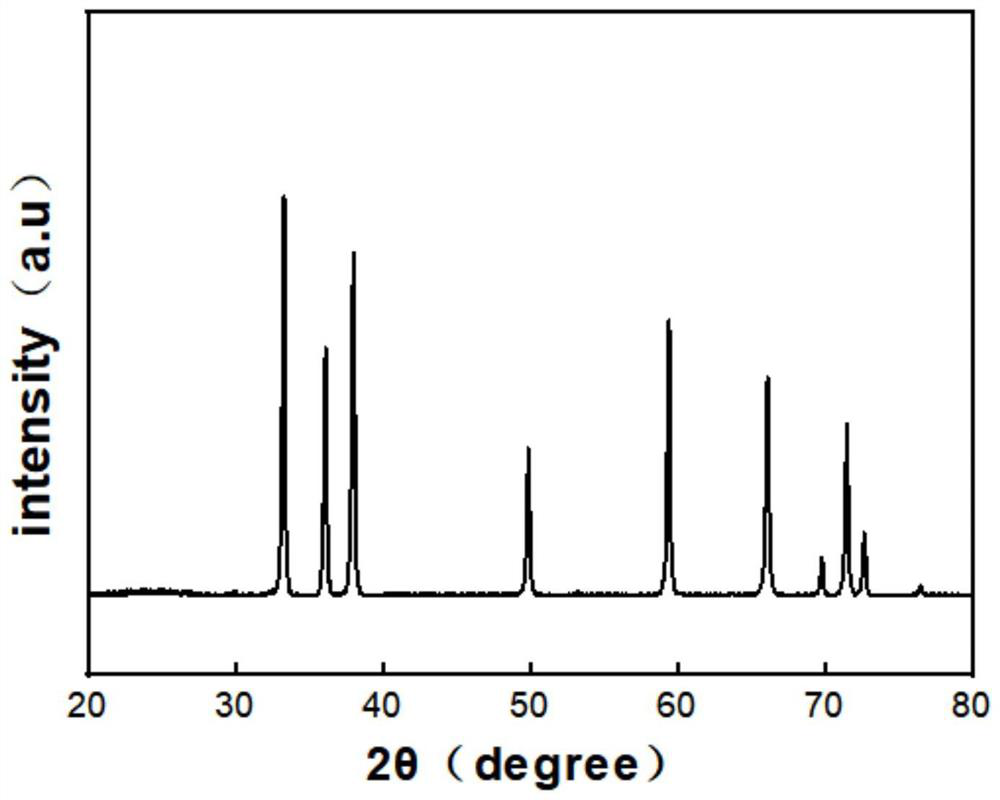

[0054] The product aluminum nitride powder is analyzed by XRD, and it can be seen that the product has no other phase diffraction peaks, and is a pure aluminum nitride product. After testing, the oxygen content of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com