Catalytic treatment process and system for converting hazardous waste oily mud sand into solid waste

A technology of catalytic treatment and mud sand, applied in sludge treatment, special compound water treatment, water/sludge/sewage treatment, etc. Reduce oil content and realize the effect of comprehensive regeneration and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

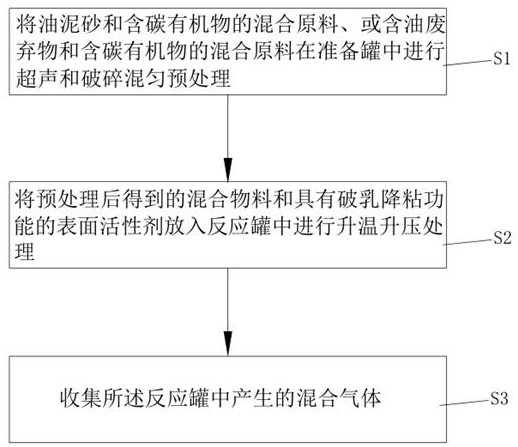

[0044] Such as figure 1 A catalytic treatment process for converting hazardous waste oily mud sand into solid waste is shown, including the following steps:

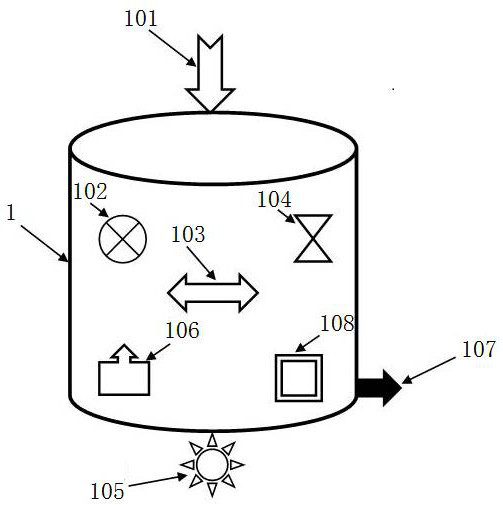

[0045] S1. The mixed raw material of oil sludge sand and carbon-containing organic matter, or the mixed raw material of oil-containing waste and carbon-containing organic matter is pretreated in the preparation tank 1 by ultrasonication, crushing and mixing. Wherein, the temperature of the mixed raw materials in the preparation tank 1 is controlled between 20-100°C.

[0046] Specifically, oily sludge sand or oily waste includes a mixture of one or more of oily sludge and oily bottoms; carbon-containing organic matter is plant straw, rice husk, wheat husk, corn ear, and kitchen waste.

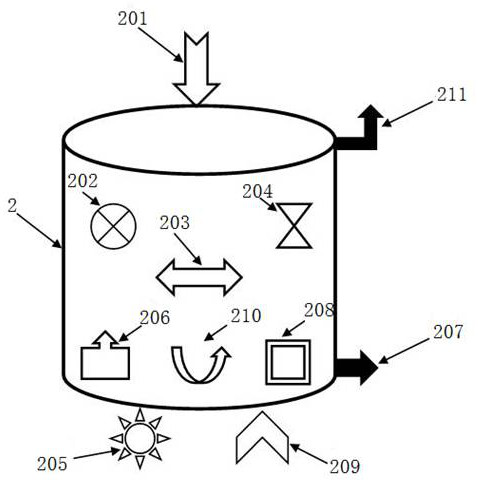

[0047] S2. Put the mixed material obtained after pretreatment and the surfactant having the function of demulsification and viscosity reduction into the reaction tank 2 for temperature raising and pressure raising treatment. Wherein, the...

Embodiment 2

[0057] Such as Figure 4 As shown, the present invention also provides a catalytic treatment system for converting hazardous waste oily mud sand into solid waste, including a preparation tank 1 , at least one reaction tank 2 and an exhaust gas treatment system 3 . The preparation tank 1, the reaction tank 2 and the waste gas treatment system 3 all adopt the preparation tank 1, the reaction tank 2 and the waste gas treatment system 3 described in the first embodiment above, and will not be repeated here.

[0058]In summary, the catalytic treatment process and system for converting hazardous waste oily mud sand into solid waste provided by the embodiment of the present invention adopts the method of combining low-temperature hydrothermal carbonization pyrolysis and surfactants to combine oily mud sand and carbon-containing Organic matter is the main raw material. After the pretreatment in the preparation tank 1, it is transferred to the reaction tank 2 for the treatment of raisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com