Bipolar plate for hydrogen fuel cell

A fuel cell and bipolar plate technology, applied in fuel cells, fuel cell parts, circuits, etc., can solve problems affecting the initial working efficiency of bipolar plates, high expansion rate of graphite plates, and damage to proton membranes, etc., to achieve improved Effects of initial work efficiency, enhanced shockproof performance, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

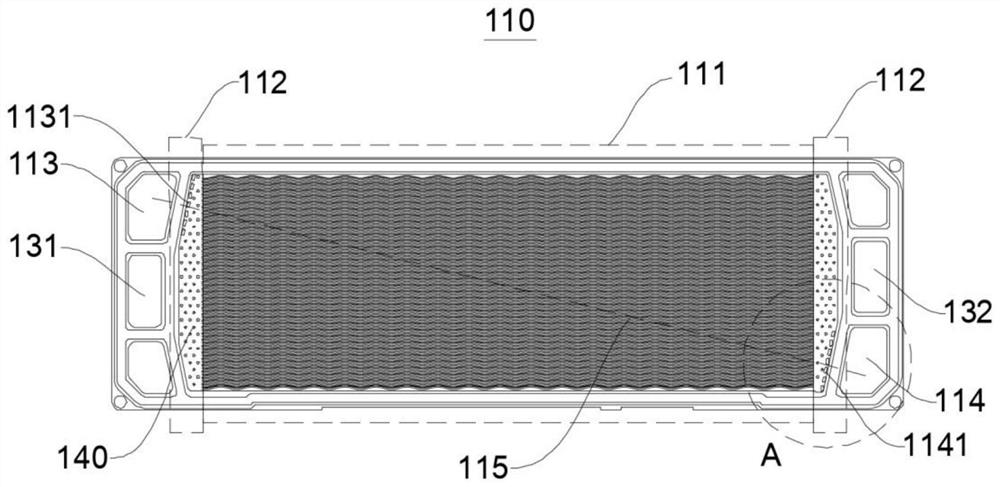

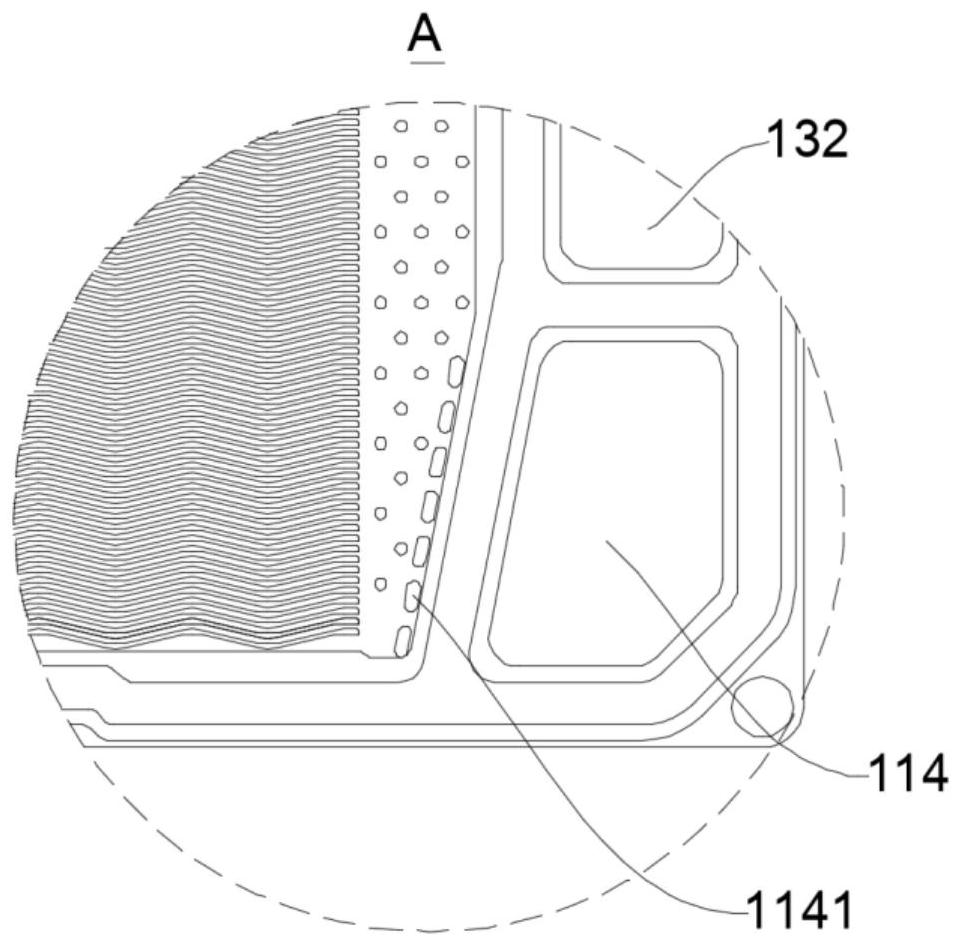

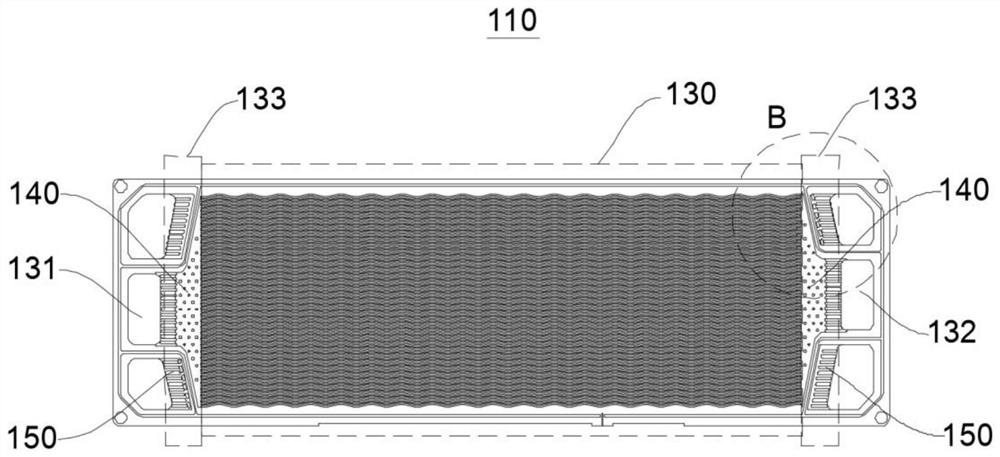

[0040] Please refer to Figure 1-Figure 7, this embodiment provides a hydrogen fuel cell bipolar plate, which includes an anode plate 110 and a cathode plate 120 . The gap between the porous graphite plates of the anode plate 110 and the cathode plate 120 is filled with fluorine gap filler (not shown in the figure). The above-mentioned fluorine caulking material can make the bipolar pole hydrophobic, so that the bipolar plate does not absorb water, reduces the expansion rate, prevents the graphite plate from being broken due to excessive expansion pressure in the confined space, and ensures the accuracy. Because the moisture contained in the gas is not absorbed by the bipolar plate during the initial work, it greatly improves the initial work efficiency and protects the battery from thirst and damage to the proton membrane during the initial work. In addition, the above-mentioned fluorine-based caulking material can withstand a temperature range of minus 35°C-260°C, which can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com