Building engineering round pipe bending device

A pipe bending device and technology for construction engineering, applied in the field of construction pipe bending, can solve problems such as low operation efficiency and limited pipe diameter range, and achieve the effects of improving efficiency, improving quality and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

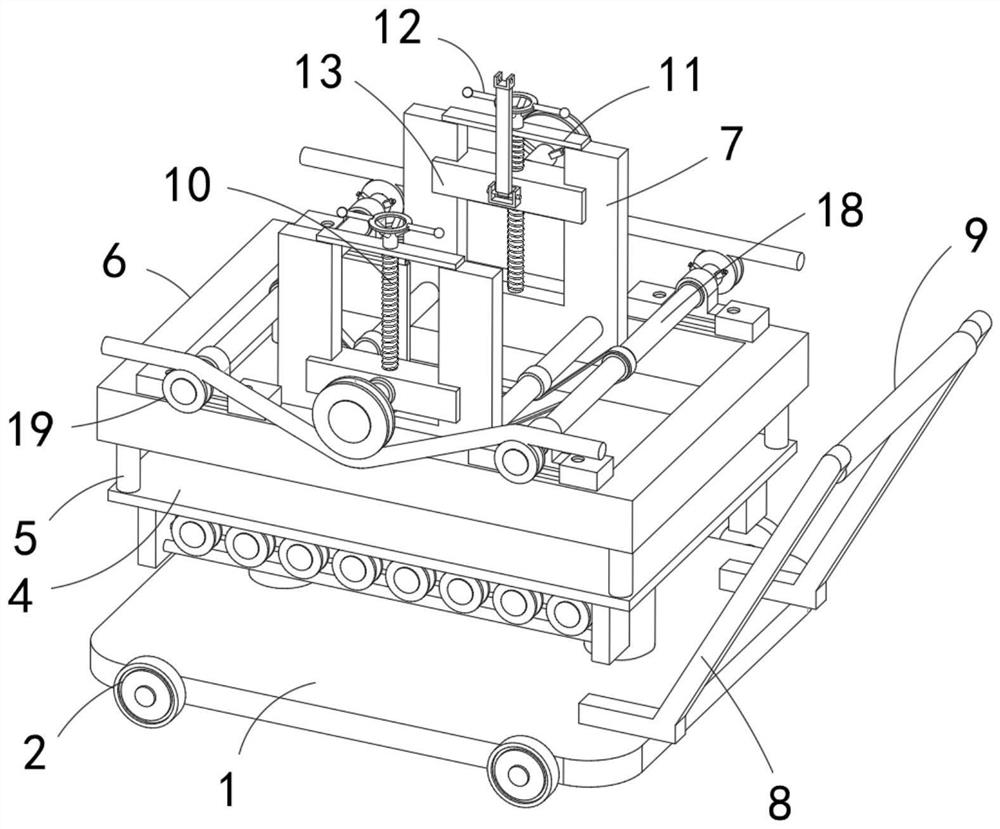

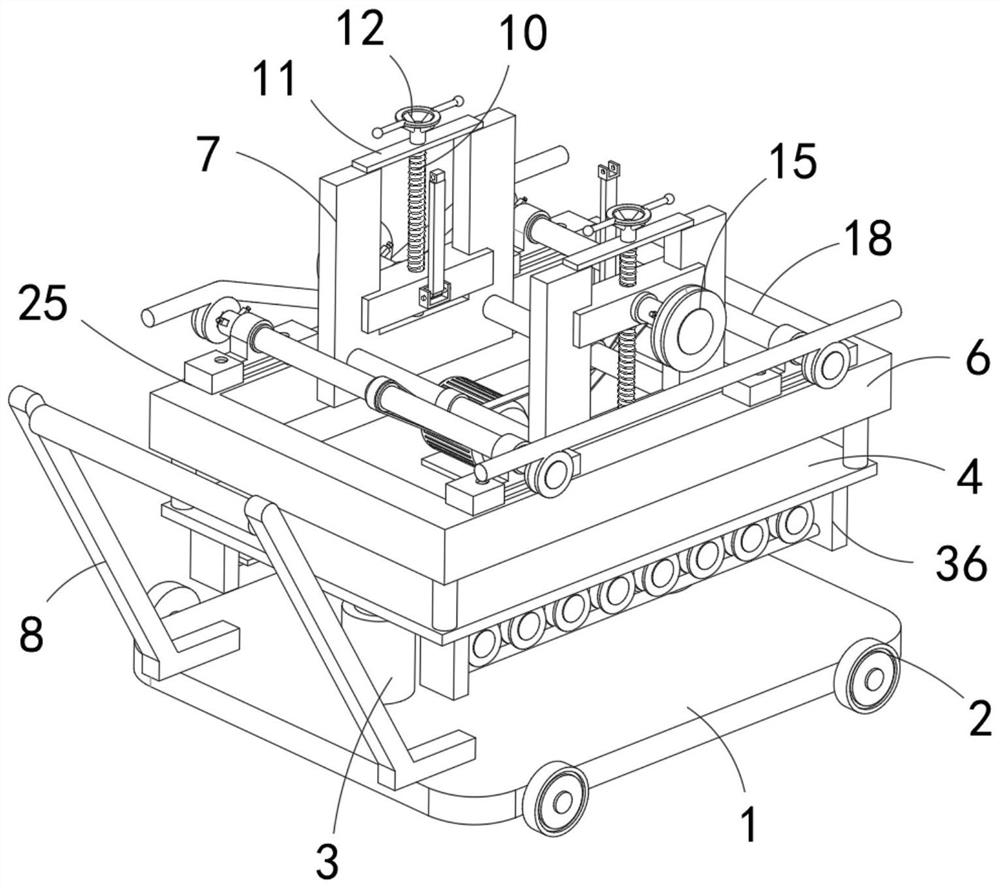

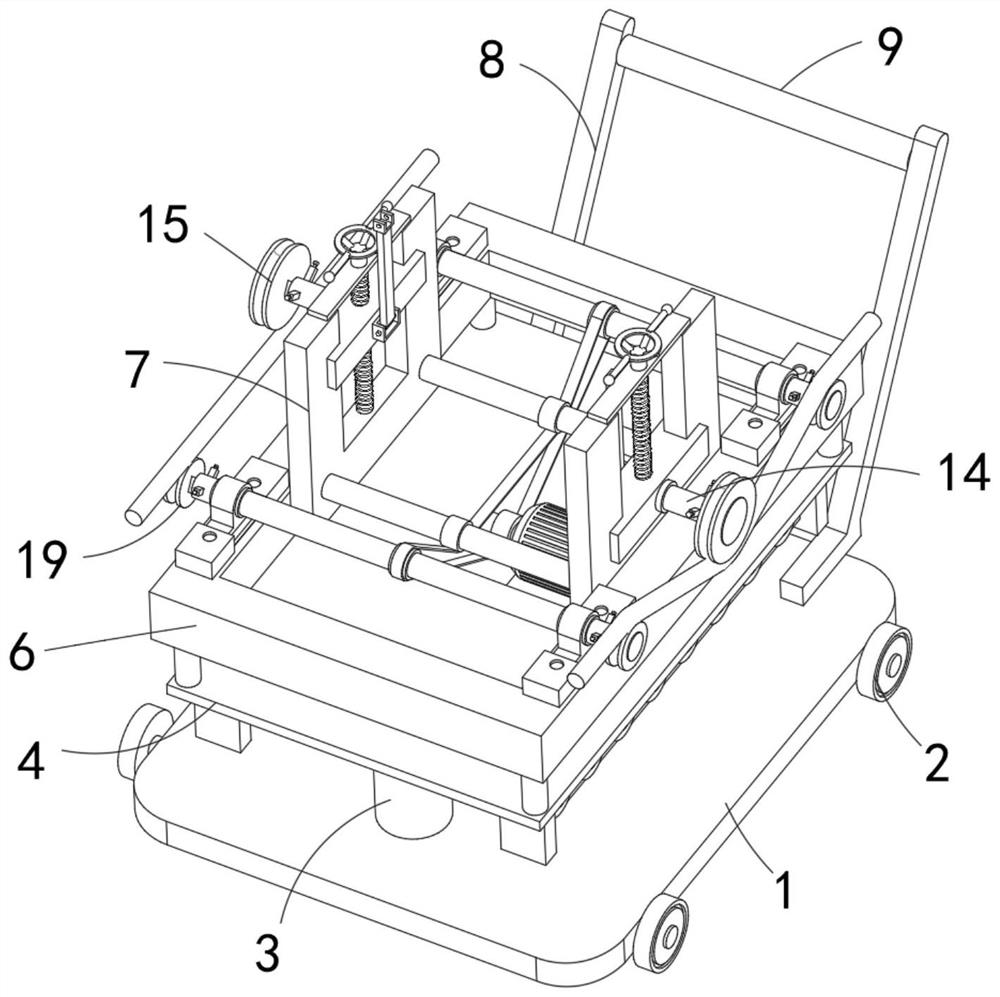

[0036] refer to Figure 1-8 , a round pipe bending device for construction engineering, comprising a base plate 1 and a push mechanism, the push mechanism is connected to the upper end of the base plate 1, the front and rear side walls of the base plate 1 are rotatably connected with rollers 2 contacting the ground, and the push mechanism includes two A tilting rod 8 fixedly connected to the upper end of the base plate 1, and a horizontal push rod 9 is fixedly connected between the side walls of the two tilting rods 8 away from the base plate 1, under the cooperative use of the pushing mechanism and a plurality of rollers 2, it can The overall position of the device is adjusted, which improves the maneuverability of the device and is convenient for the operator to bend the pipe.

[0037]Wherein, the upper end of the base plate 1 is fixedly connected with a hydraulic rod 3, and the telescopic end of the hydraulic rod 3 is fixedly connected with a support plate 4, and the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com