Clamping device for welding and robot

A technology of clamping mechanism and clamping parts, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of welding robot surface damage and low workpiece positioning accuracy, achieve welding efficiency, improve welding efficiency, and ensure The effect of welding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

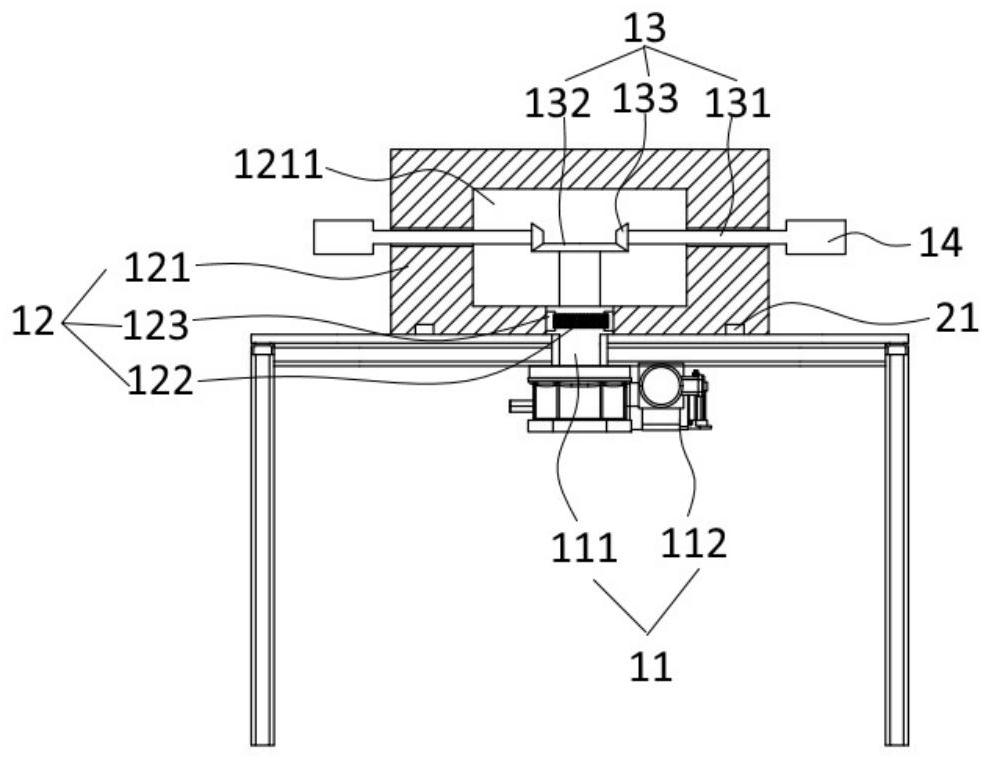

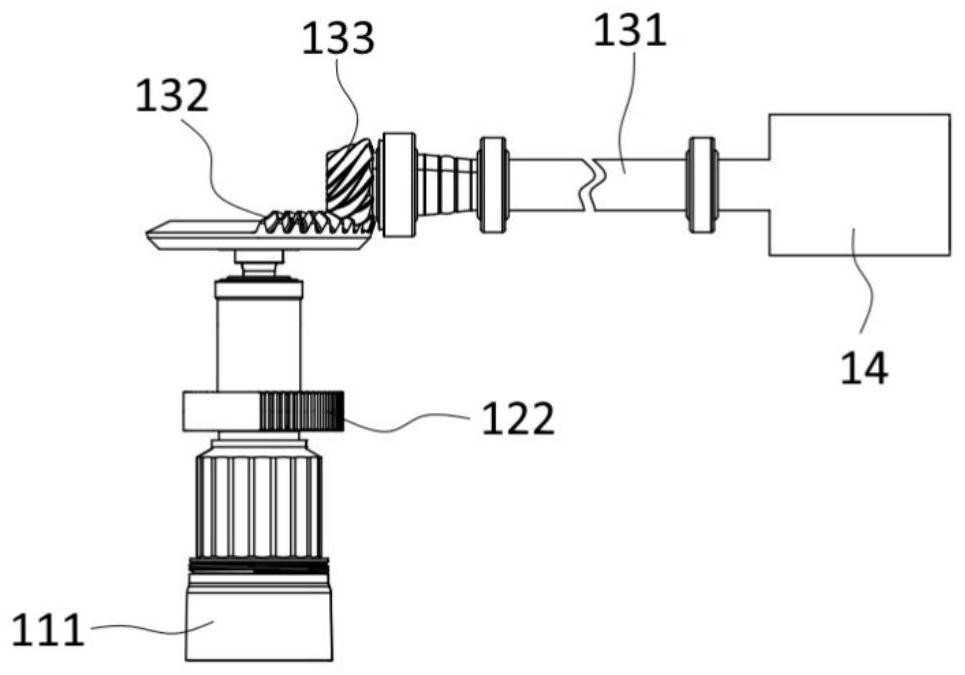

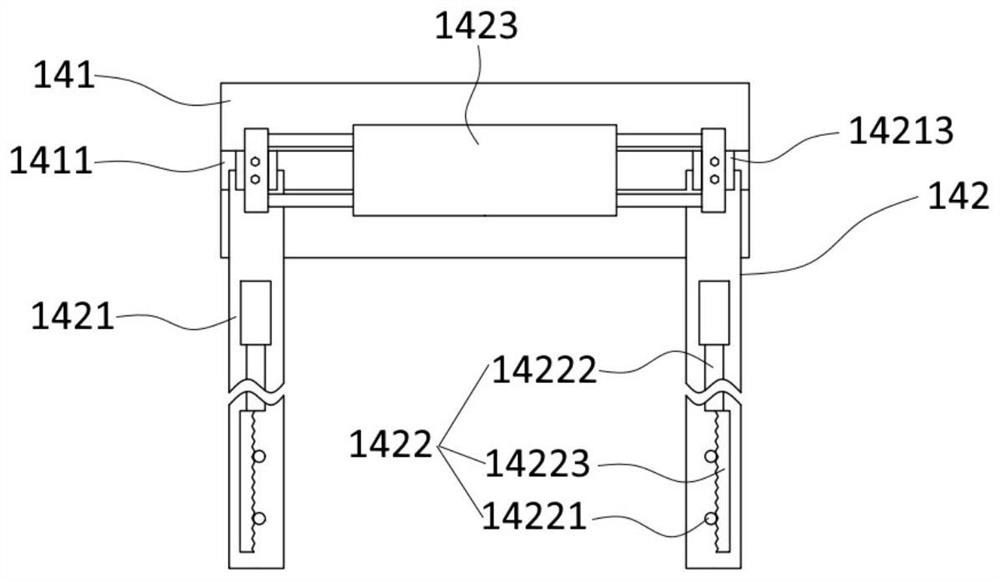

[0053] combine figure 1 and figure 2 The clamping device 1 for welding provided in this embodiment includes a driving mechanism 11 , a first rotating mechanism 12 , a second rotating mechanism 13 and a clamping mechanism 14 .

[0054] Specifically, the driving mechanism 11 includes a driving shaft 111 and a driving assembly 112 . The drive shaft 11 is arranged vertically. The bottom end of the drive shaft 11 is connected with the drive assembly 112 to realize circumferential rotation. The drive assembly 112 includes a drive motor and a reducer. The output end of the drive motor is connected to the input end of the reducer to output power, and the output end of the reducer is coaxially connected to the drive shaft 111 to realize deceleration and drive the drive shaft 111 to rotate at a low speed.

[0055] The first rotating mechanism 12 is connected with the drive shaft 111 to realize intermittent rotation in the horizontal plane. The first rotating mechanism 12 includes ...

Embodiment 2

[0066] combine Figure 5 , this embodiment provides a robot for welding. The robot includes a gripping device 1 , a working platform 2 , a mechanical arm 3 and a welding torch 4 .

[0067] Specifically, the clamping device 1 adopts the clamping device 1 for welding in the first embodiment, and its specific structure has been described in detail in the first embodiment, and will not be repeated here.

[0068] The working platform 2 is arranged horizontally, and several supporting frames 5 are arranged at the bottom thereof. The shell of the reducer is fixedly connected with the bottom surface of the working platform 2, and the bottom end of the drive shaft 111 penetrates the working platform 2 downwards and is fixedly connected with the output end of the reducer. The rotating part 121 is placed flat on the top surface of the working platform 2. In order to ensure the stability of the rotating part 121 rotation, the working platform 2 is provided with an annular guide rail 21,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com