Three-degree-of-freedom parallel robot

A robot and degree of freedom technology, applied in the field of robotics, can solve problems such as damage, decreased motion accuracy, difficulty in ensuring the position and attitude accuracy of the moving platform, and achieve high-precision, high-reversibility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

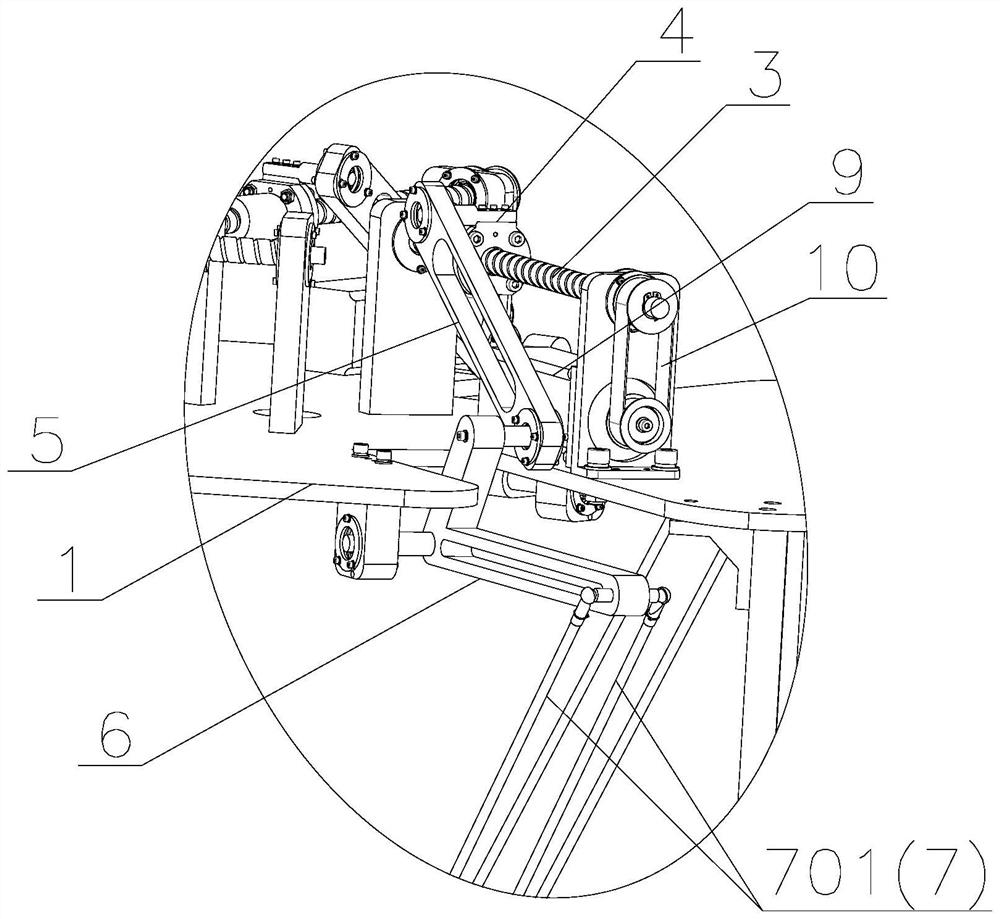

[0018] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

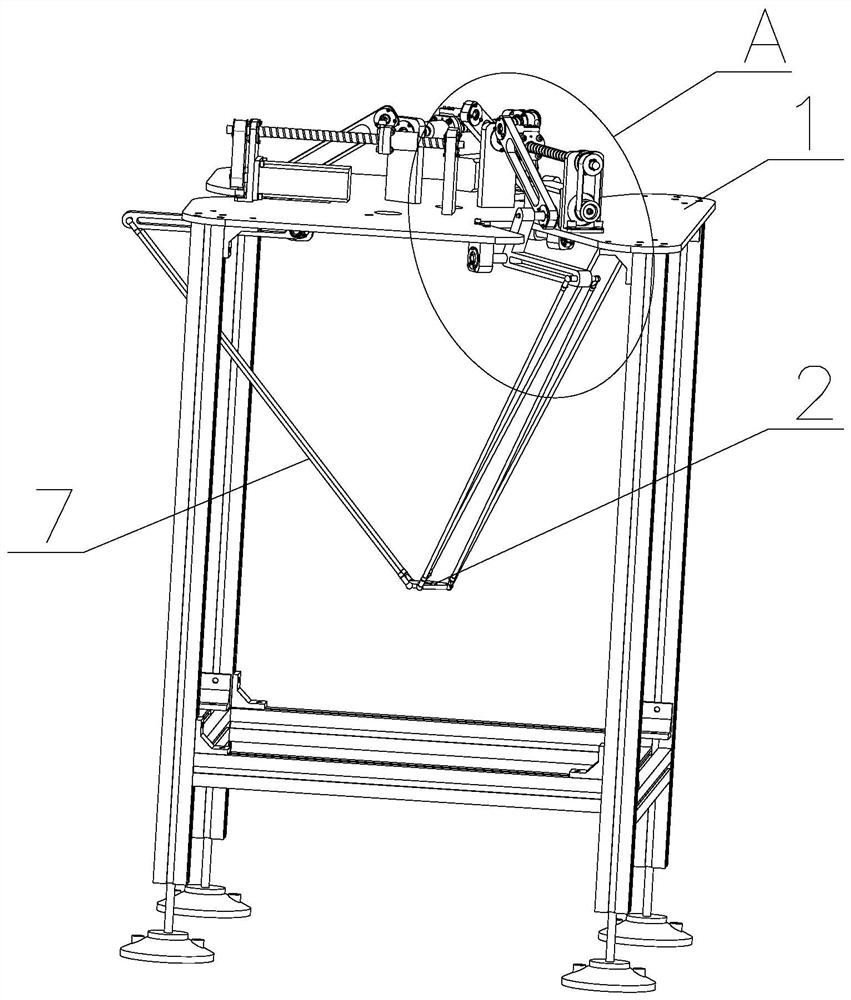

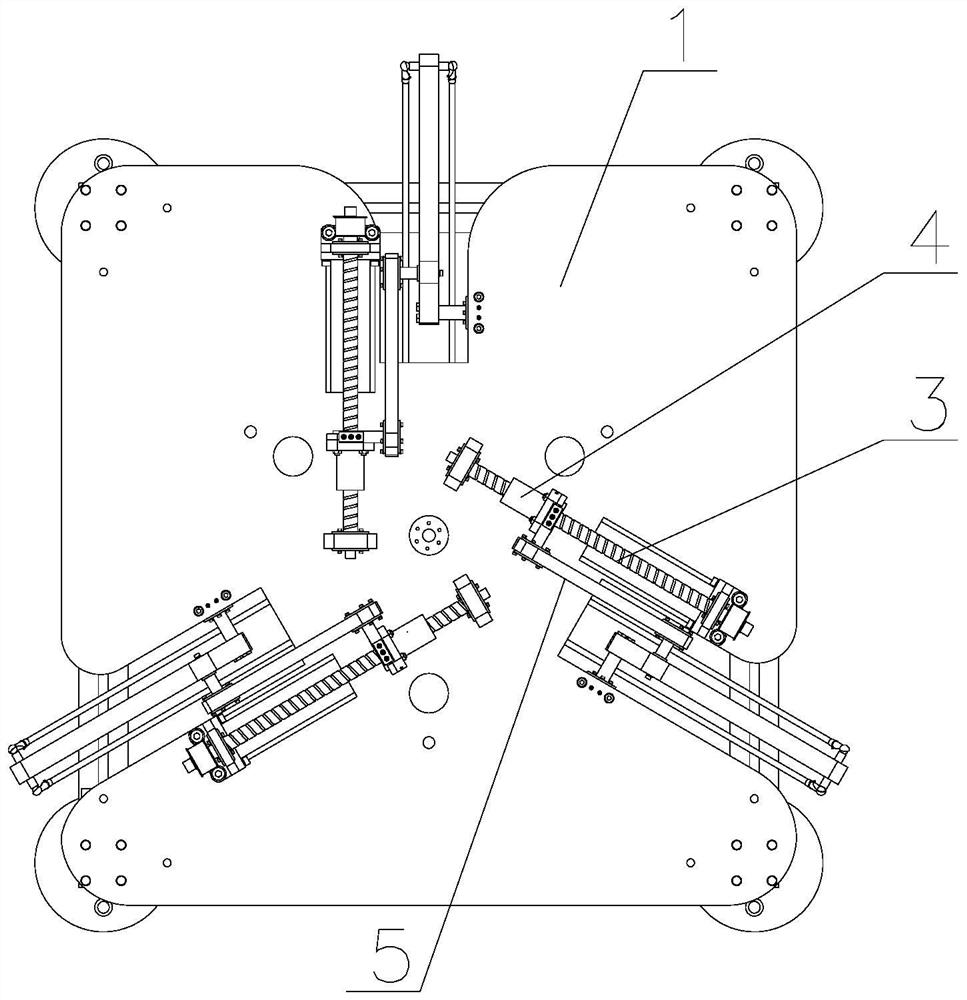

[0019] Such as Figure 1-4 As shown, a three-degree-of-freedom parallel robot of the present invention includes a fixed platform 1, a moving platform 2, and three sets of drive rod assemblies, each set of drive rod assemblies is correspondingly provided with a drive assembly, and the drive assembly includes a The ball screw 3 that is rotatably connected to the fixed platform 1 is screwed with a screw nut 4. Each of the ball screws 3 is symmetrical along the center of the fixed platform 1. The transmission rod assembly It includes a driving arm 5, an L-shaped transmission arm 6 and a connecting piece 7. One end of the driving arm 5 is hinged to the outer wall of the screw nut 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com