Template cleaning mechanism based on injection molding machine and cleaning method thereof

A technology for injection molding machines and templates, which is applied to the template cleaning mechanism and its cleaning field based on injection molding machines. It can solve the problems of inconvenient replacement, inability to replace the cleaning mechanism, and inability to control the cleaning structure. Or maintenance, cleaning effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

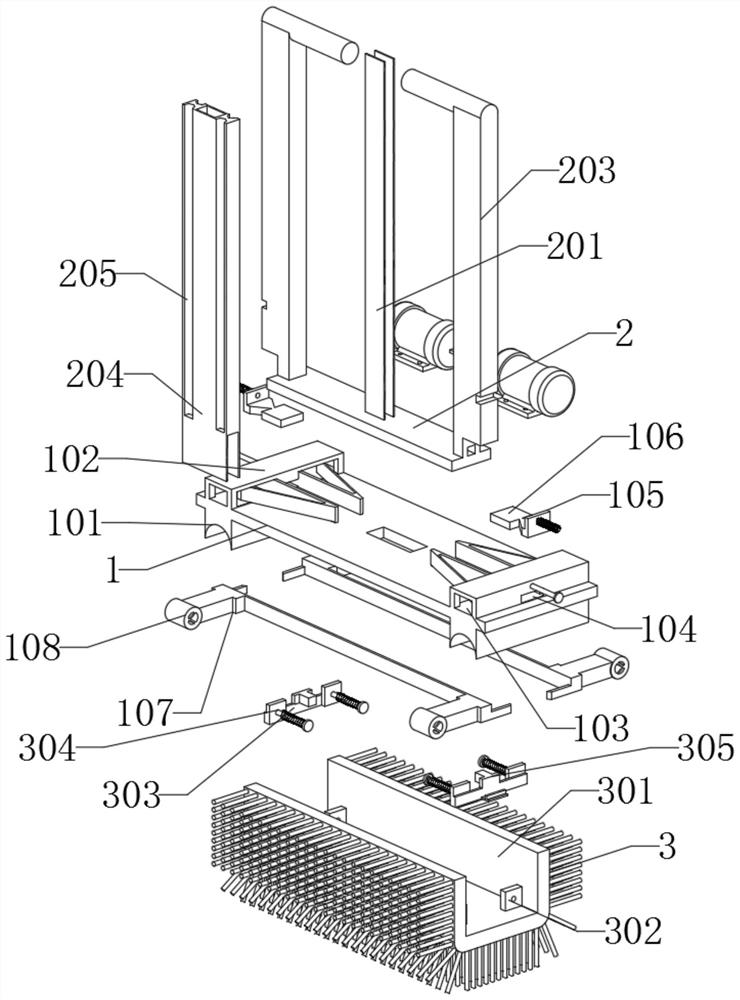

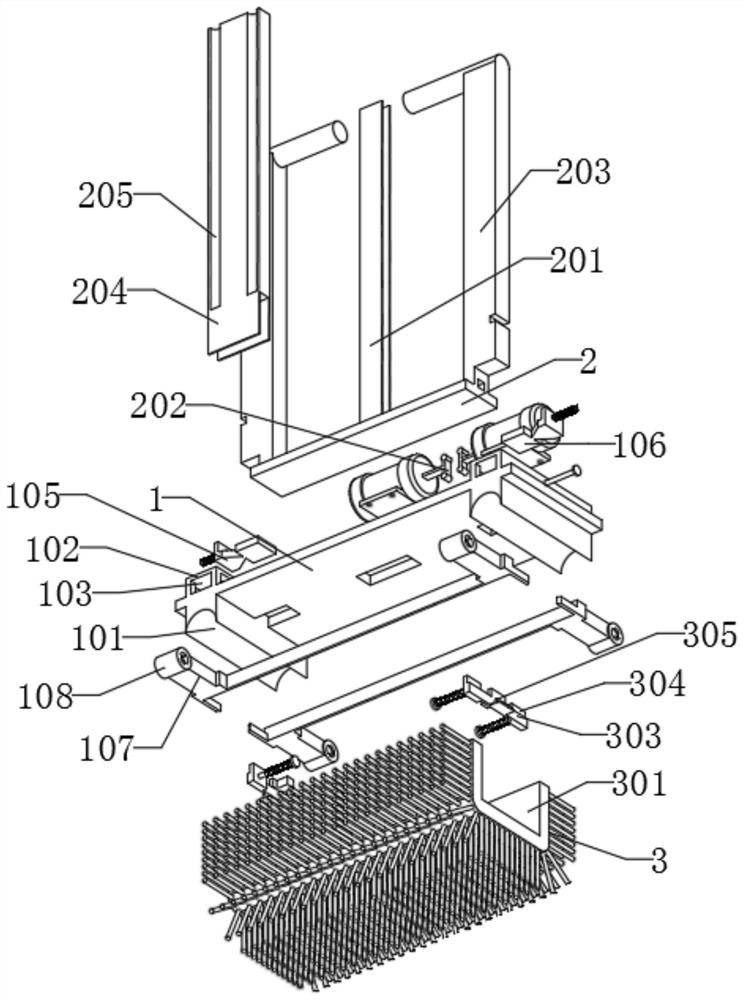

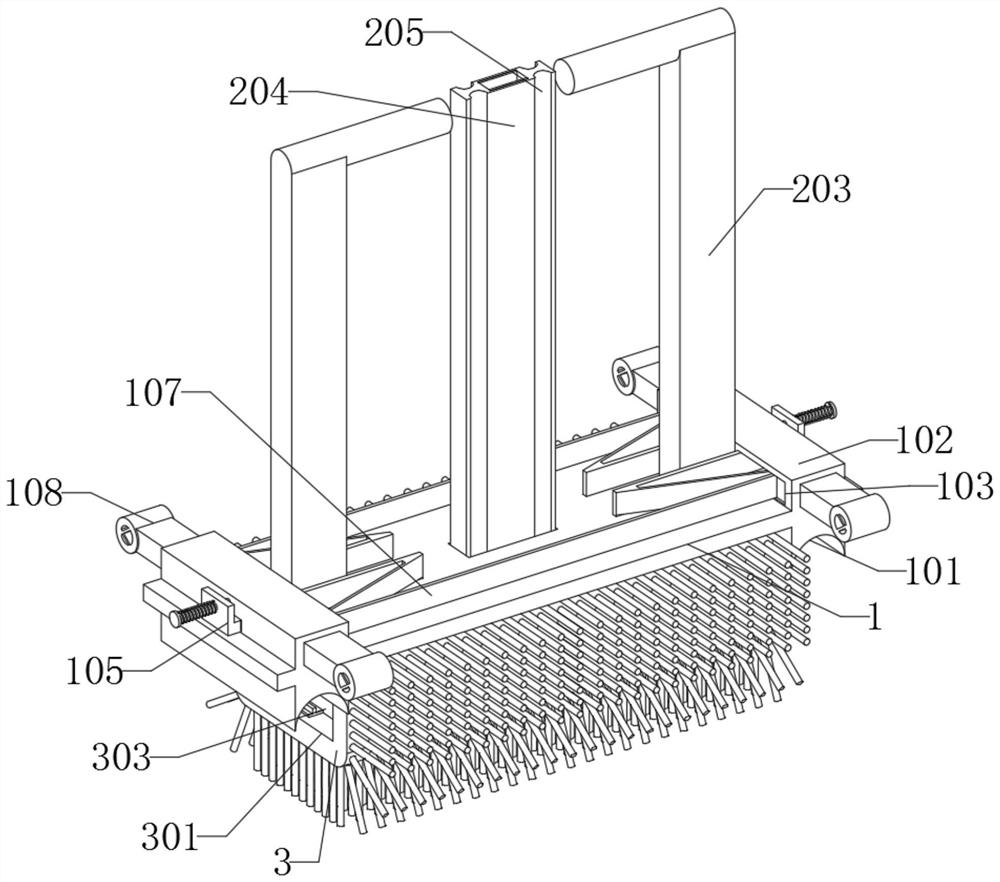

[0061] as attached figure 1 to attach Figure 8 Shown:

[0062] The invention provides a template cleaning mechanism based on an injection molding machine and a cleaning method thereof, including a main body 1; the main body 1 is a rectangular plate structure, and the inside of the main body 1 is provided with three rectangular grooves, and the bottom of the main body 1 is installed with a mounting plate 2; Mounting plate 2, the mounting plate 2 includes a slow-down mechanism, the top middle of the mounting plate 2 is equipped with a slow-falling mechanism, the mounting plate 2 is a rectangular plate-shaped structure, and two vibrating motors are arranged on both sides of the top of the mounting plate 2. The bottom of the plate 2 is fixed with a cleaning part 3; the cleaning part 3 has a rectangular structure, and both sides of the bottom of the cleaning part 3 are arc-shaped structures, and the bottom of the cleaning part 3 is provided with evenly arranged bristles.

[0063...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com