A refueling gun for oil and gas recovery

A refueling gun, oil and gas technology, used in packaging, liquid distribution, conveying or transferring devices, transportation and packaging, etc., can solve problems such as the failure of the valve core groove to be smoothly engaged, the failure of the diaphragm to automatically reset, and the weakening of the elasticity of the second spring. , to achieve uniform force, reduce volume and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below with reference to the accompanying drawings.

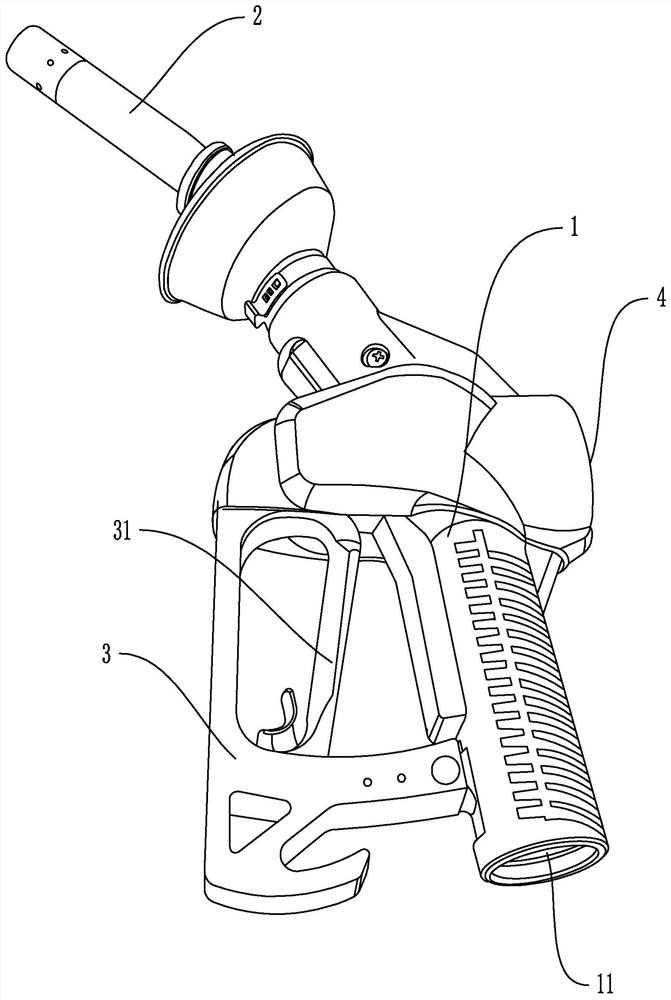

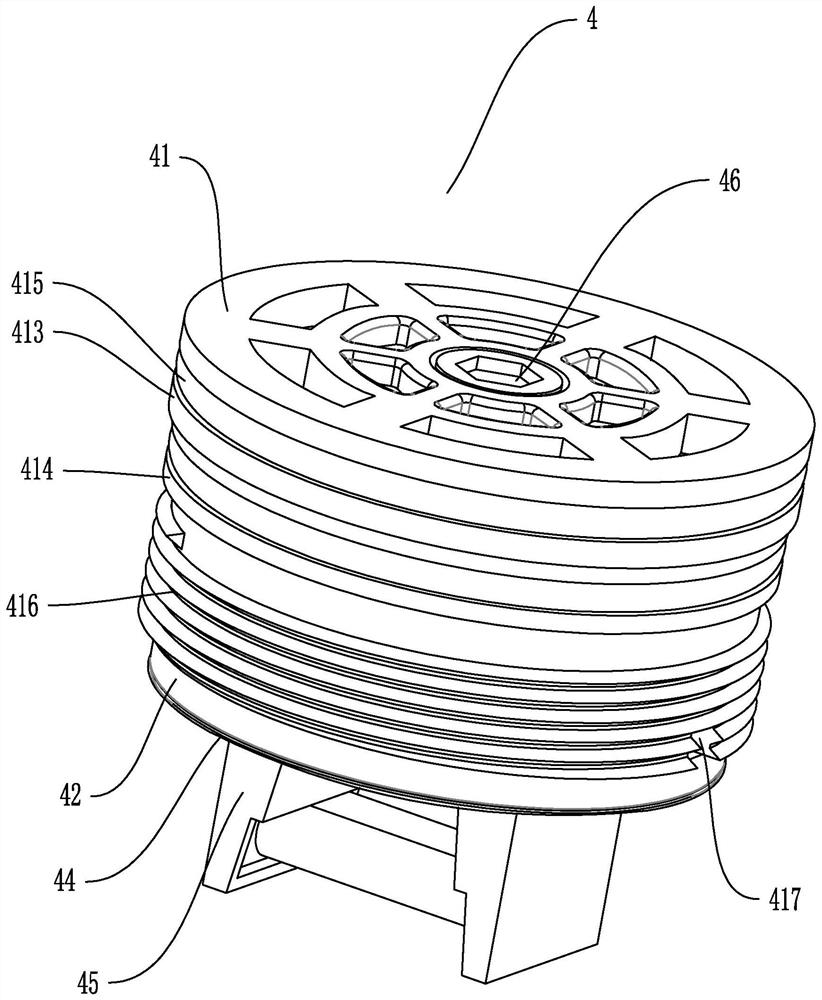

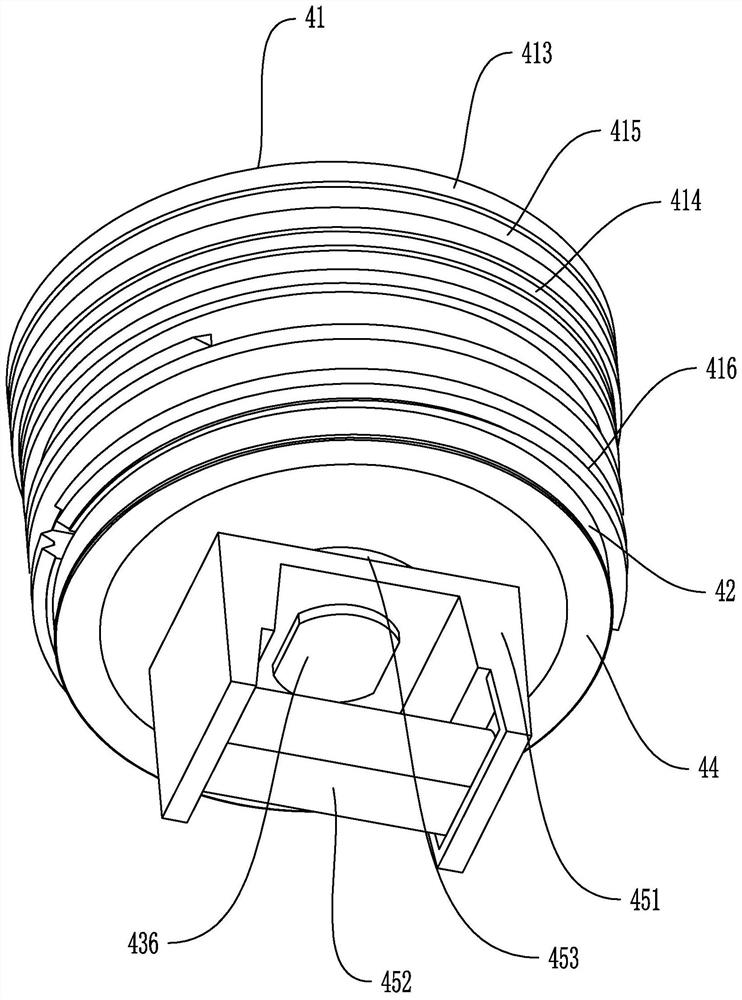

[0035] This embodiment discloses an oil and gas recovery fuel gun, such as Figures 1 to 6 As shown, it includes a refueling gun body 1, a refueling gun barrel 2 and a refueling gun frame 3 connected with the refueling gun body 1, and the refueling gun frame 3 is provided with a matching refueling trigger 31, and the refueling gun body 1 is provided with There is a refueling cavity 11 adapted to the refueling gun barrel 2. The oil-gas separation valve assembly and the ejector spool are arranged in the refueling cavity 11. The refueling gun body 1 is provided with a self-sealing matching with the ejector spool. The valve assembly 4, the self-sealing valve assembly 4 includes a matching self-sealing valve body 41 and a valve body cover plate 42. The self-sealing valve body 41 is provided with an elastic assembly 43 that is adapted to it, and the lower side of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com