Anti-blue contact contact lens, composition thereof, and manufacturing method

A technology of contact lens and manufacturing method, applied in the field of its composition and manufacturing, contact lens, can solve problems such as protection, inability to completely block blue light, inability to provide anti-blue light, etc., to achieve the effect of reducing eye fatigue and improving the sense of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

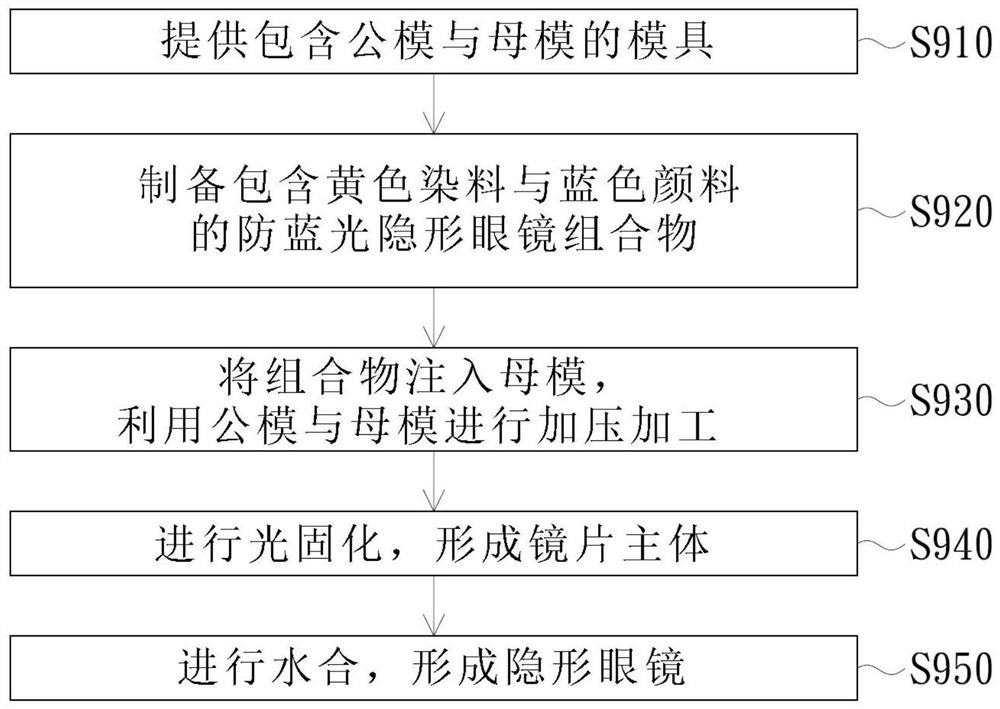

Method used

Image

Examples

Embodiment approach 1

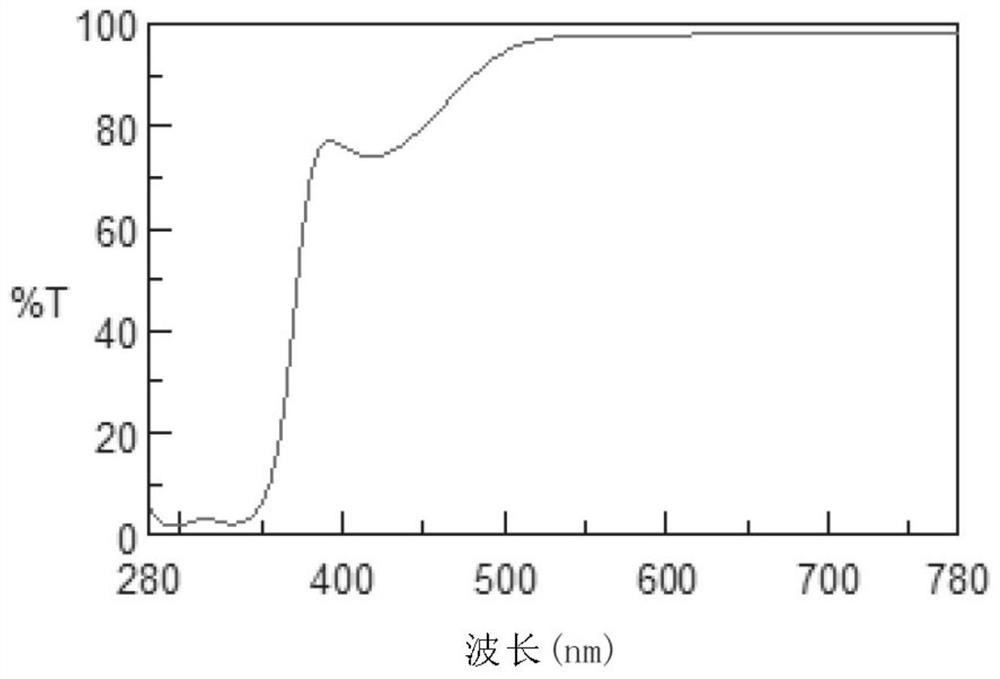

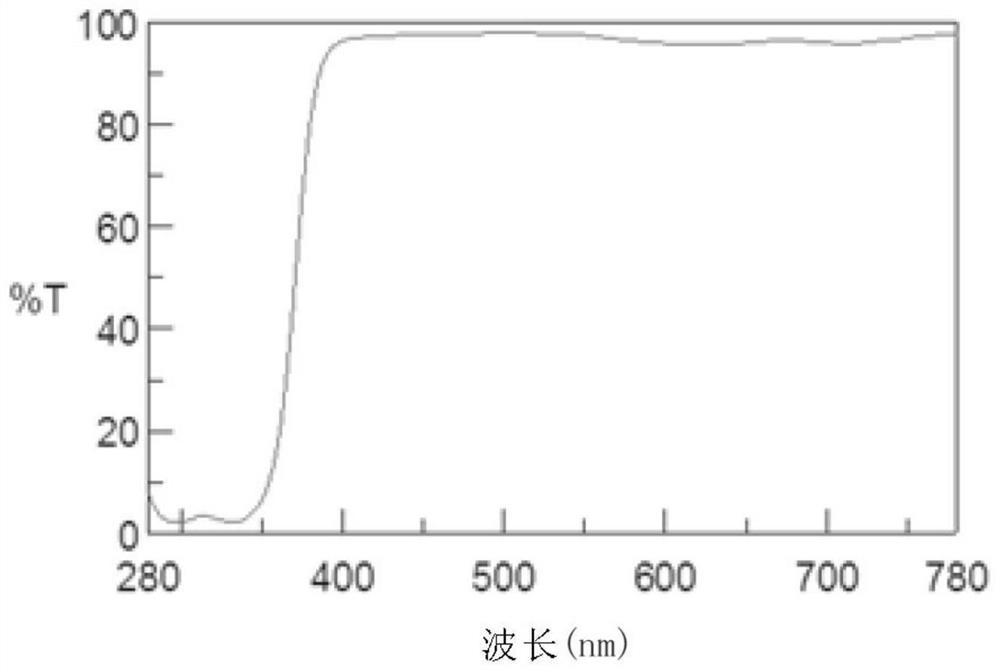

[0061] In Embodiment 1, compositions 1 to 6 were prepared according to step S920, and a control group (control group 1) was prepared separately. Table 1 shows the content of each component in each of compositions 1 to 6 and control group 1 . The difference between control group 1 and compositions 1-6 lies in the content of yellow dye and blue pigment.

[0062] [Table 1]

[0063] Table 1: Distribution ratio of each component of compositions 1 to 6 and the control group (control group 1)

[0064]

[0065] It should be noted that in Table 1, the total amount of the yellow dye and the blue pigment increases in the order of compositions 1-6, and preferably the amount of the yellow dye increases in the order of compositions 1-6. The amount of blue pigment can also be increased, but embodiments of the invention are not limited thereto. Compositions 1-6 may contain the same amount of blue pigment.

[0066] Next, step S930 will be described. In the process S930, the composition...

Embodiment approach 2

[0069] In Embodiment 2, the compositions 1 to 6 of Embodiment 1 were used in steps S930 to S950, respectively, and sterilized to form samples 1 to 6 of anti-blue light contact lenses. The control group (control group 1) was also treated under the same conditions to manufacture contact lenses of the control group (control group 1). Table 2 shows parameters used in Embodiment 2.

[0070] [Table 2]

[0071] Table 2: Manufacturing parameters

[0072]

[0073] It should be noted that in Embodiment 2, compositions 1 to 6 were used under the same conditions to form contact lenses. However, it should be understood that in each step of S930-S950 and sterilization, Compositions 1-6 can also be treated under other conditions, such as photocuring time, hydration temperature or buffer solution, which are different from those recorded in Table 2, respectively. In addition, the parameters described in Table 2 can also be used for compositions other than compositions 1-6.

[0074] For ...

Embodiment approach 3

[0093] In Embodiment 3, composition 7 was prepared according to step S920, and a control group (control group 2) was prepared separately. The yellow dye contained in composition 7 accounts for 0.13wt% of its total weight, and the blue pigment is added in such a manner that the ratio of the yellow dye to the blue pigment is 7:1. Control 2 also contained 0.13 wt% yellow dye, but no blue pigment. Next, according to steps S930-S950, using the composition 7 and the control group 2, the sample 7 of the anti-blue light contact lens and the contact lens of the control group (control group 2) were respectively manufactured and their appearances were observed. show the result in Figure 4A ~ Figure 4B .

[0094] Figure 4A The left side is a commercially available anti-UV water blue contact lens (control group 3), and the right side is an anti-blue contact lens (sample 7). Figure 4B The contact lens of the control group (control group 2) is on the left, and sample 7 is on the right...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| barrier rate | aaaaa | aaaaa |

| barrier rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com