Centrifugal pump fault diagnosis method based on self-search characteristic peak value and local range

A fault diagnosis, centrifugal pump technology, applied in pump control, non-variable-capacity pumps, machines/engines, etc., can solve problems such as increased maintenance difficulty, time-consuming and laborious state, misjudgment, etc., to improve diagnosis efficiency and diagnosis accuracy Sex, overcoming the effects of over-dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

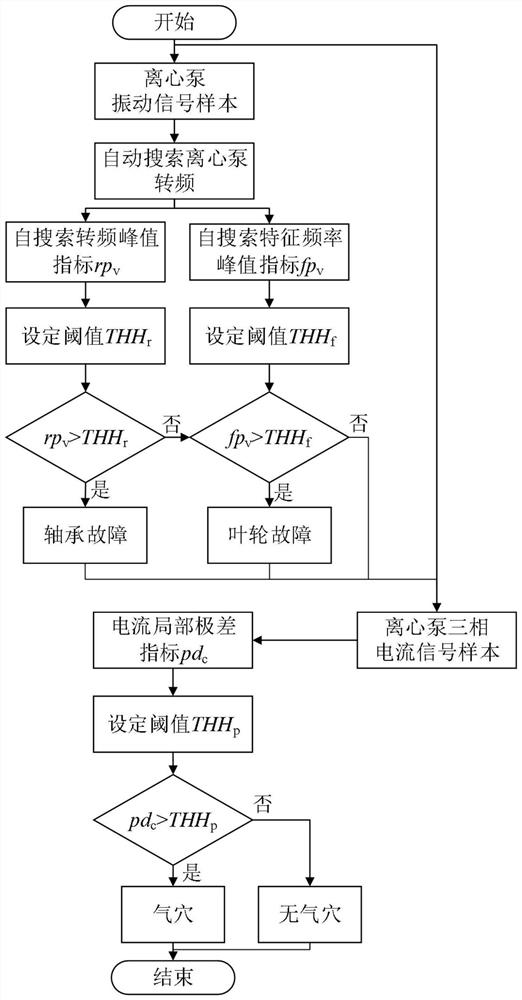

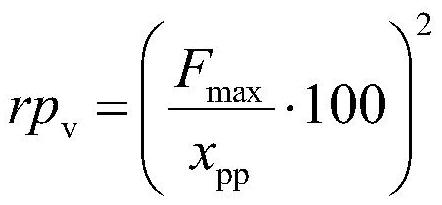

Method used

Image

Examples

Embodiment

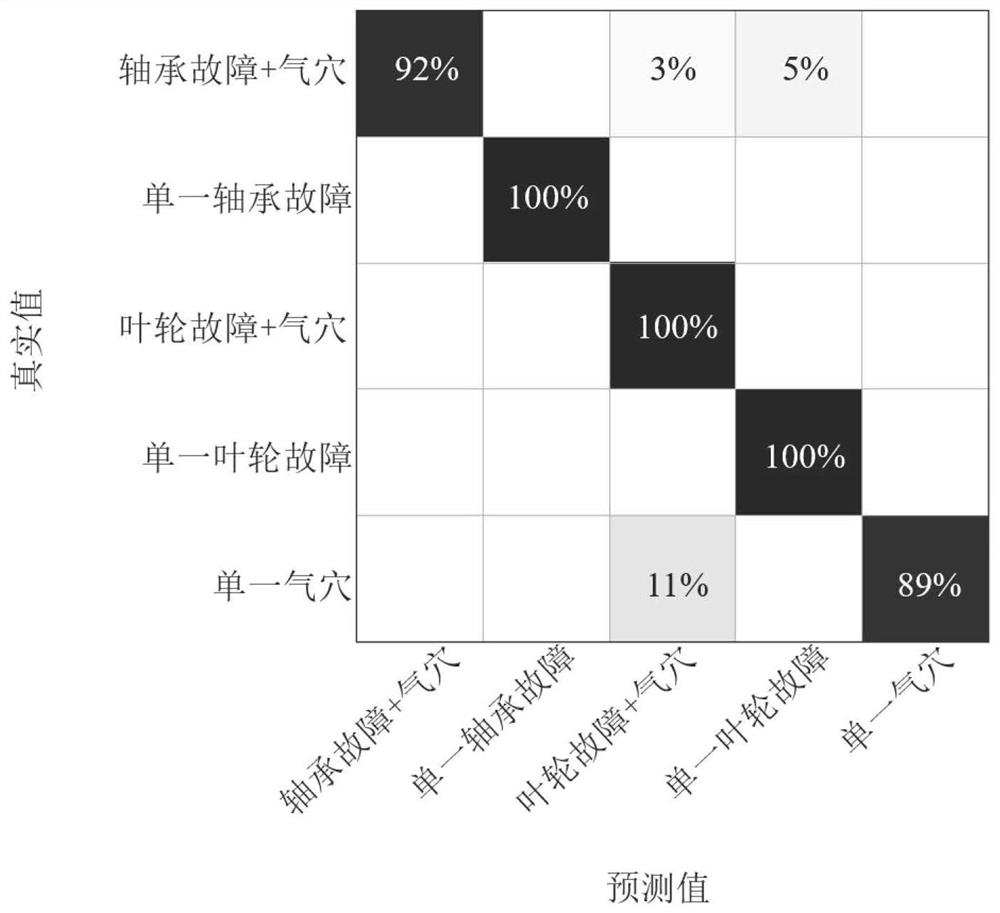

[0068] Embodiment: Take the application of centrifugal pump failure experimental data as an example to verify the feasibility of the present invention.

[0069] The experimental data of centrifugal pump faults obtained are the experimental data of different fault types of centrifugal pumps measured at three different speeds of 30Hz, 40Hz, and 50Hz. The centrifugal pump faults include bearing faults, impeller faults, and cavitation. Cavitation may be accompanied by Bearing faults and impeller faults exist at the same time, so the fault types can be further subdivided into bearing fault + cavitation, single bearing fault, impeller fault + cavitation, single impeller fault and single cavitation, each set of data needs to determine whether there is air hole. Centrifugal pump bearing models are 6306 and 6307, including NSK and SKF. The theoretical fault characteristic frequencies of the two types of bearings at the rotation frequency f are shown in Table 1 and Table 2 respectively:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com