Geotextile performance detection device for trapezoidal groove

A detection device and geotextile technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of high tensile breaking requirements of geotextiles, gravel blown on geotextiles and rolling down, accumulation of rainwater, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

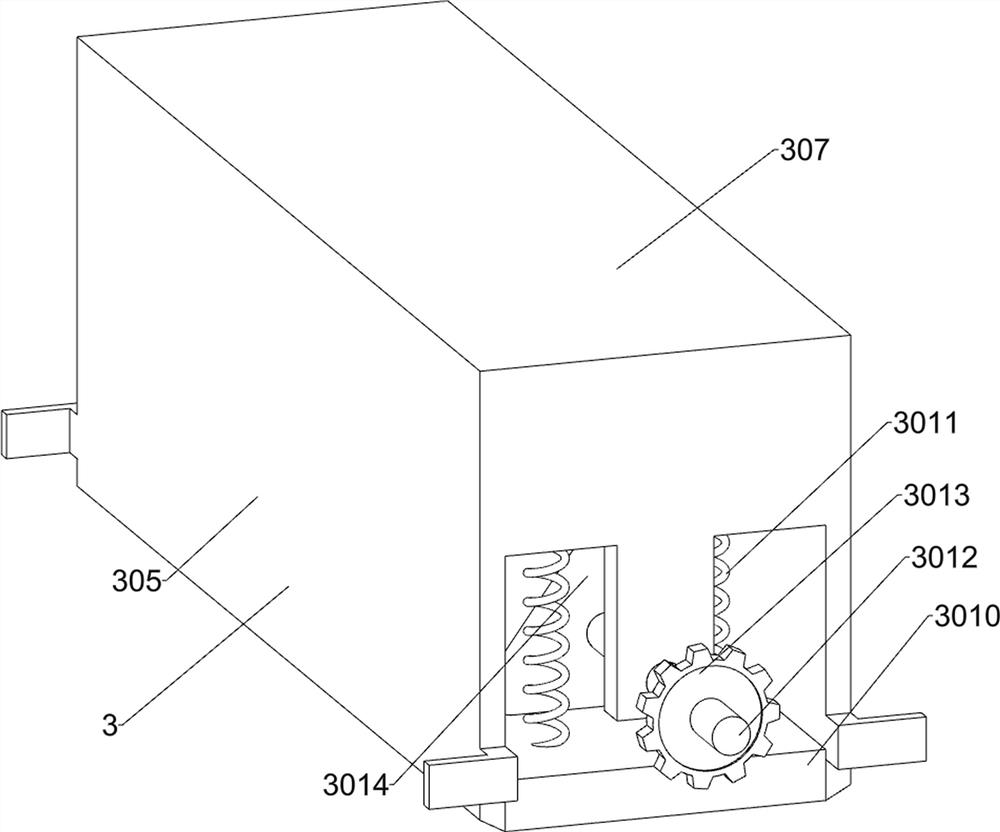

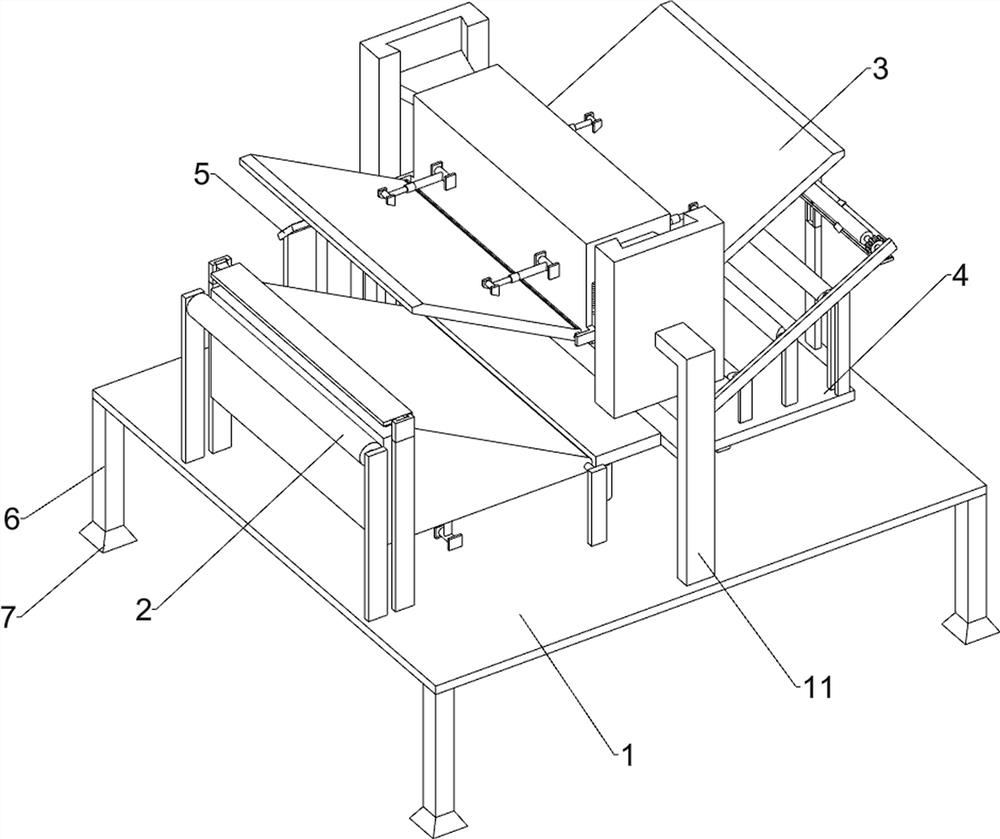

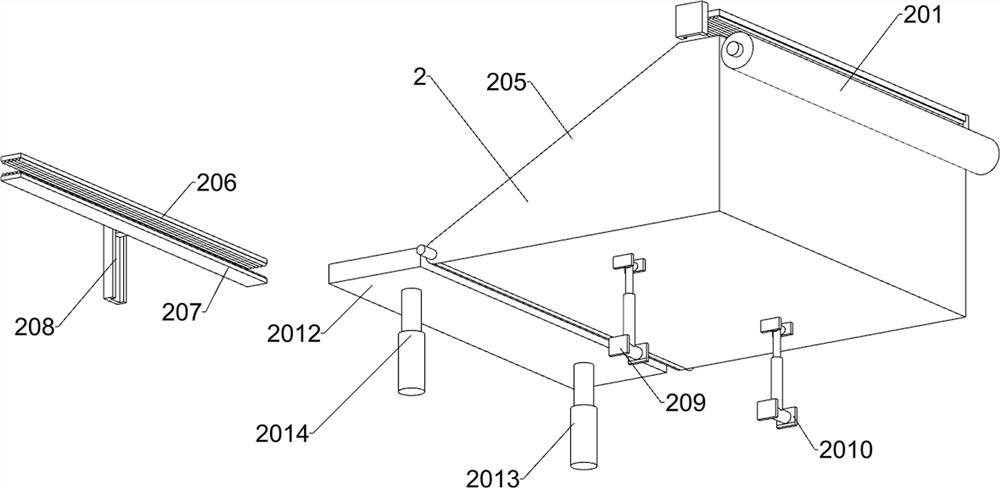

[0031] A geotextile performance testing device for trapezoidal grooves, such as Figure 1-10 As shown, it includes an underframe 1, a laying unit 2, a tensile breakage detection unit 3, a puncture resistance detection unit 4, a control panel 5, a pillar 6, an anti-skid pad 7, a first bracket 8, a second bracket 9, a third bracket Bracket 10 and fourth bracket 11; base frame 1 is connected with laying unit 2; base frame 1 is connected with anti-puncture detection unit 4; base frame 1 is connected with four sets of pillars 6; base frame 1 is connected with first bracket 8 The bottom frame 1 is connected with the second bracket 9; the bottom frame 1 is connected with the third bracket 10; the bottom frame 1 is connected with the fourth bracket 11; The anti-pull detection unit 3 is connected with the fourth support 11; the anti-puncture detection unit 4 is connected with the first support 8; the control panel 5 is connected with the second support 9; the four sets of pillars 6 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com