Self-rolling shielding sleeve with three-layer structure and preparation method thereof

A three-layer structure, self-rolling technology, applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problem of light aging resistance, high temperature resistance, poor puncture resistance, easy damage to pipelines, and fabrics. Breakage and other problems, to achieve the effect of excellent shielding effect, excellent light aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

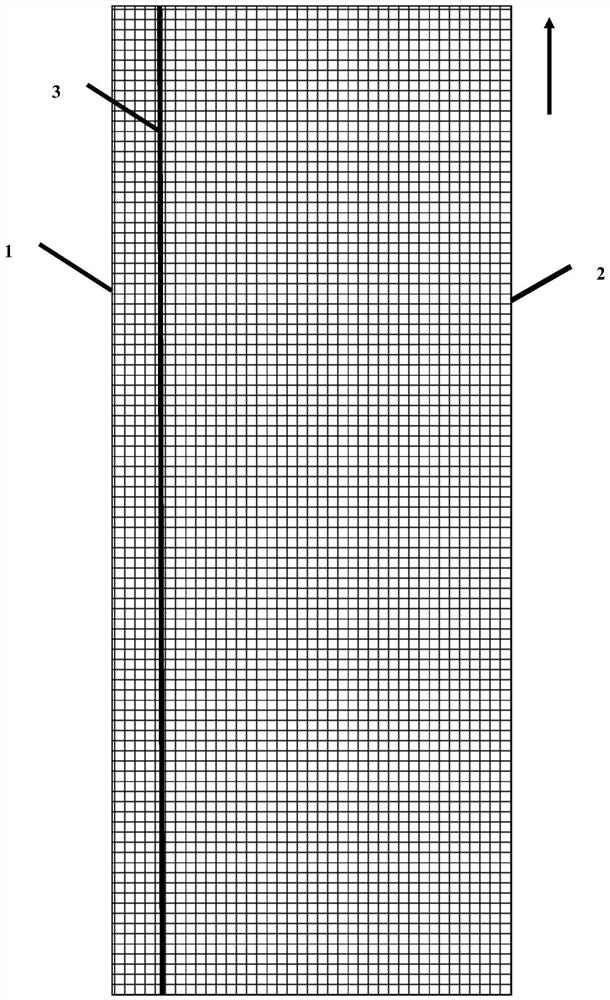

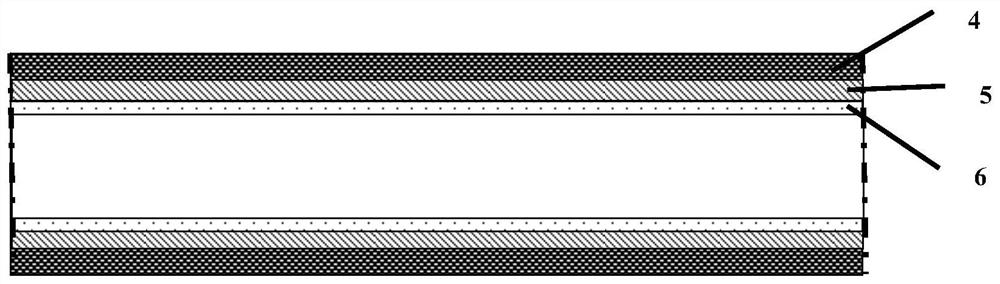

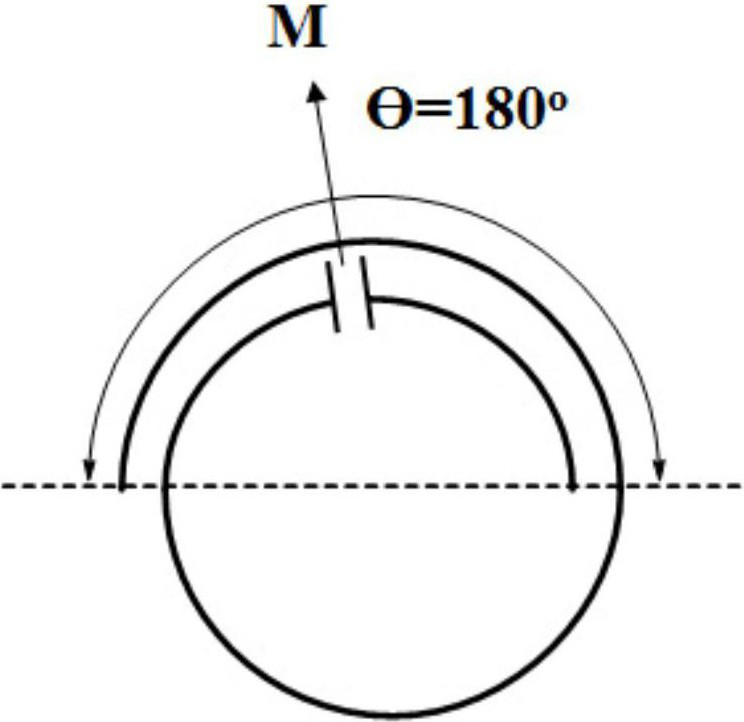

[0054] Preparation of the self-rolling sleeve layer:

[0055] The warp yarn is composed of 5 strands of non-thermoplastic polyimide organic fiber with a linear density of 600D and combined at constant tension. The weft yarn is a single thermoplastic polyimide organic fiber monofilament with a monofilament diameter of 0.50mm, which is woven into a plain weave tape in warp and weft. At the same time, a free edge along the warp direction is woven with 2 strands of white aramid organic fiber with a maximum diameter marking line, and the shortest distance between the marking line and the free edge of the warp is 7mm. Wherein, the warp yarn has a weaving density of 30 strands / inch, and the weft yarn has a weaving density of 30 strands / inch.

[0056] The woven sheet-like woven fabric is passed through the treatment tank with a solid content of 15% anti-mold liquid (anti-mold agent GN-A626, purchased from Dongguan Guangneng Shoe Material Co., Ltd., the same below) at a speed of 2m / min...

Embodiment 2

[0064] Preparation of the self-rolling sleeve layer:

[0065] The warp yarn is composed of 3 strands of aramid organic fiber with a multifilament linear density of 1000D at constant tension, and the weft yarn is 2 strands of polyphenylene sulfide organic fiber monofilament with a monofilament diameter of 0.20mm and 3 strands of 20 polyimide yarns. The plain weave belt structure is formed into warp and weft. At the same time, a free edge along the warp direction is woven with 2 strands of white aramid organic fiber with a maximum diameter marking line. The shortest distance between the marking line and the free edge of the warp is 7mm. Wherein, the weaving density of the warp yarn is 25 strands / inch, and the weaving density of the weft yarn is 25 strands / inch.

[0066] The woven sheet-shaped woven fabric is passed through the treatment tank with a solid content of 20% mildew-proof liquid at a speed of 2m / min, the drying hot roller at 200°C, and the treatment tank with a solid c...

Embodiment 3

[0073] Preparation of the self-rolling sleeve layer:

[0074] The warp yarn is composed of 8 strands of multifilament linear density 1200D polybenzoxazole organic fiber with constant tension, the weft yarn is 1 thermoplastic polyimide organic fiber monofilament with a monofilament diameter of 0.60mm and 5 strands of 15 non-thermoplastic polyimide Amine yarn, woven into a warp and weft twill weave tape structure, and a free edge along the warp direction is woven with a maximum diameter marking line with 2 strands of white aramid organic fiber, and the shortest distance between the marking line and the free edge of the warp is 10mm. Wherein, the weaving density of the warp yarn is 20 strands / inch, and the weaving density of the weft yarn is 20 strands / inch.

[0075] The woven sheet-like woven fabric is sequentially passed through a treatment tank with a solid content of 30% mold-proof liquid at a speed of 8m / min, a drying hot roller at 280°C, and a treatment tank with a solid co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com