Efficient anti-interference cable shielding tape production process

A production process and technology of shielding tape, applied in the field of high-efficiency anti-interference cable shielding tape production process, can solve the problems of poor structural shielding effect, need manual operation, complex production process, etc., and achieve high production efficiency and good anti-interference shielding effect. , the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

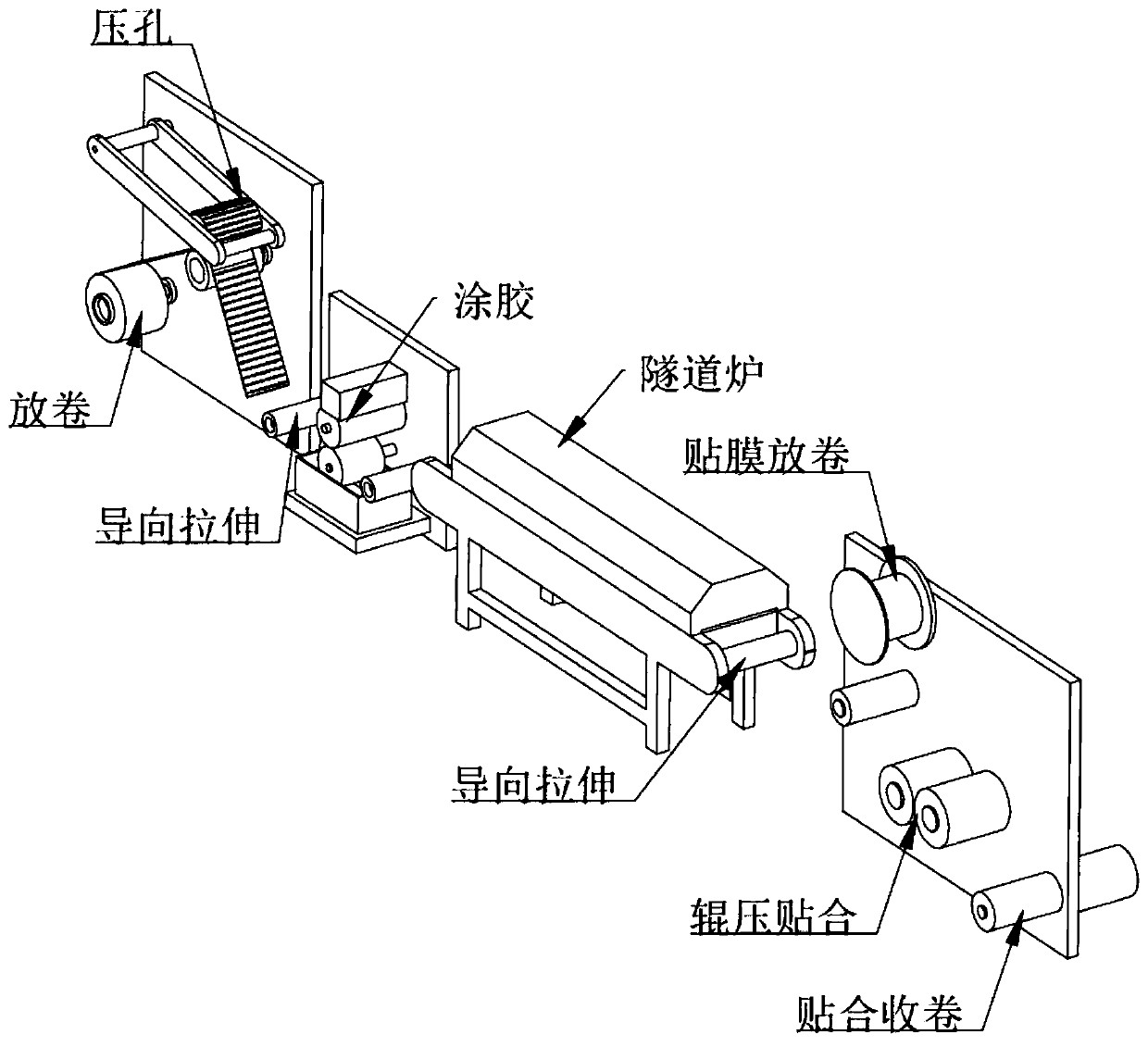

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

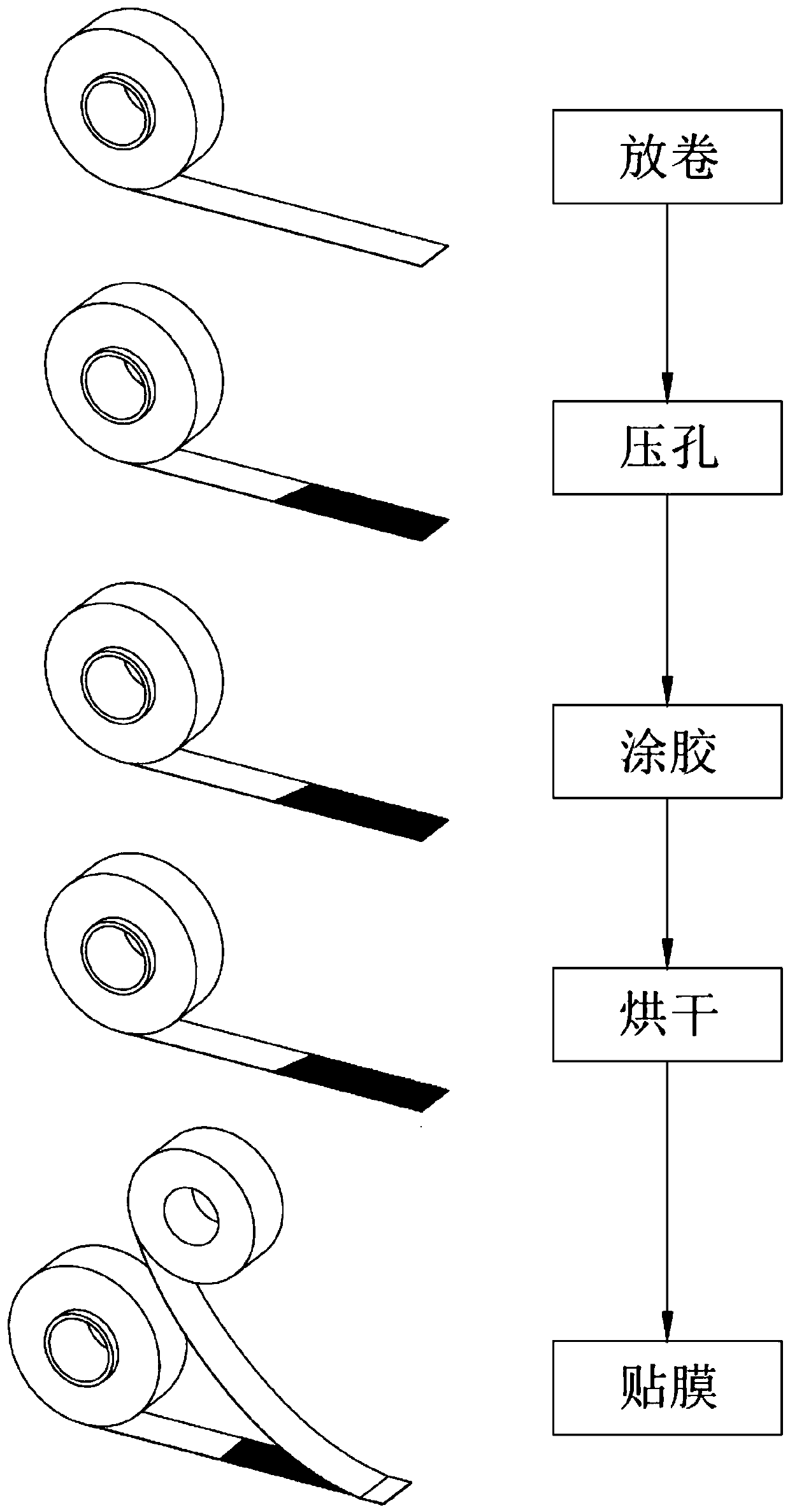

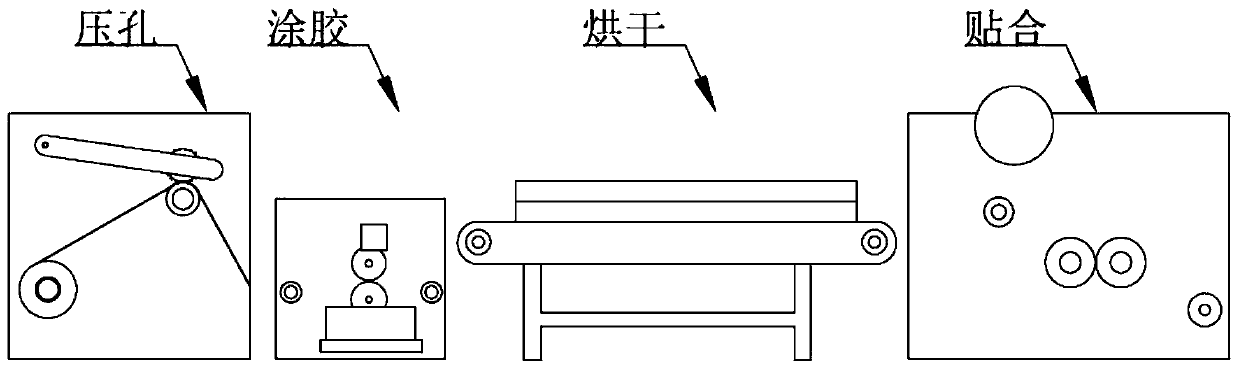

[0031] like Figure 1 ~ Figure 3 As shown, a high-efficiency anti-interference cable shielding tape production process includes the following steps:

[0032] Step 1, unwinding and driving the base material;

[0033] Step 2, processing the base material in the unwinding process to form several pressing holes;

[0034] Step 3, applying glue to the base material after processing to form the press hole;

[0035] Step 4, drying the glue coated on the substrate;

[0036] Step 5, sticking a film on the surface of the dried base material to form a shielding tape.

[0037] In step 1, the base material is one of aluminum foil or copper foil, and the thickness of the base material is 0.01-0.05mm, which can play a better shielding effect in the structure, and at the same time, the rolling holes are convenient, the forming effect is good, and the structure high strength.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com