A kind of self-winding casing and its preparation method

A casing and self-winding technology, which is applied in textiles, textiles, papermaking, fabrics, etc., can solve the problems of affecting casing protection, poor anti-puncture performance, warp damage, etc., and achieves good mildew and waterproof performance and simple structure , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

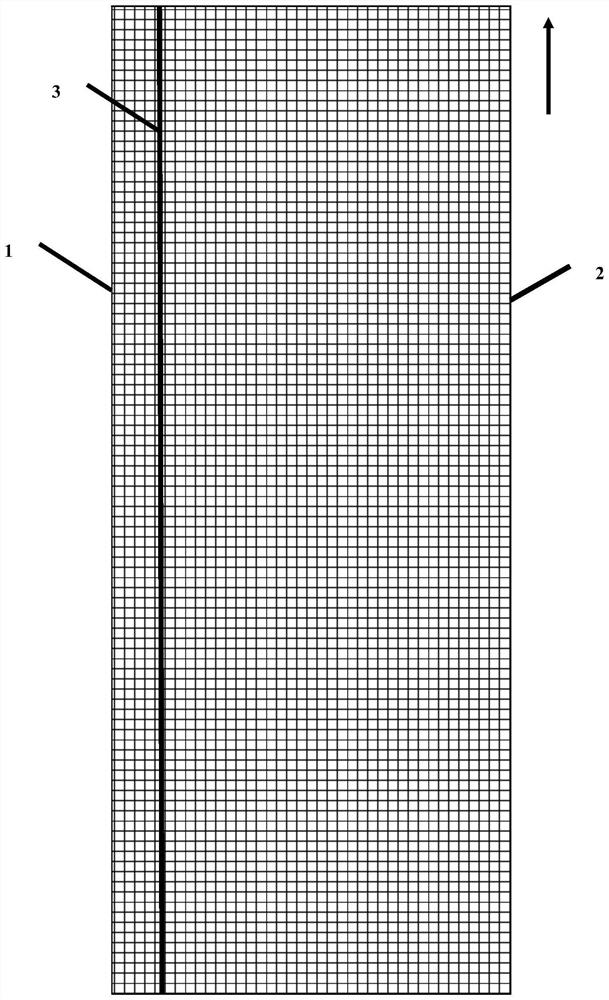

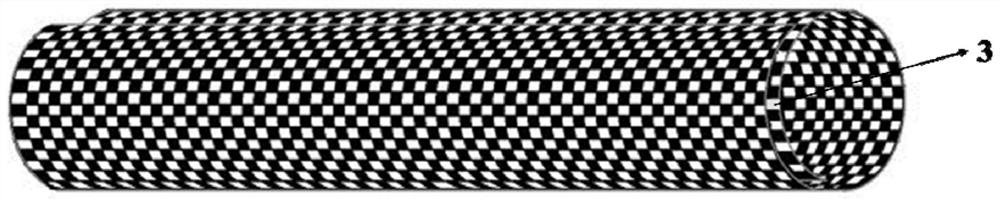

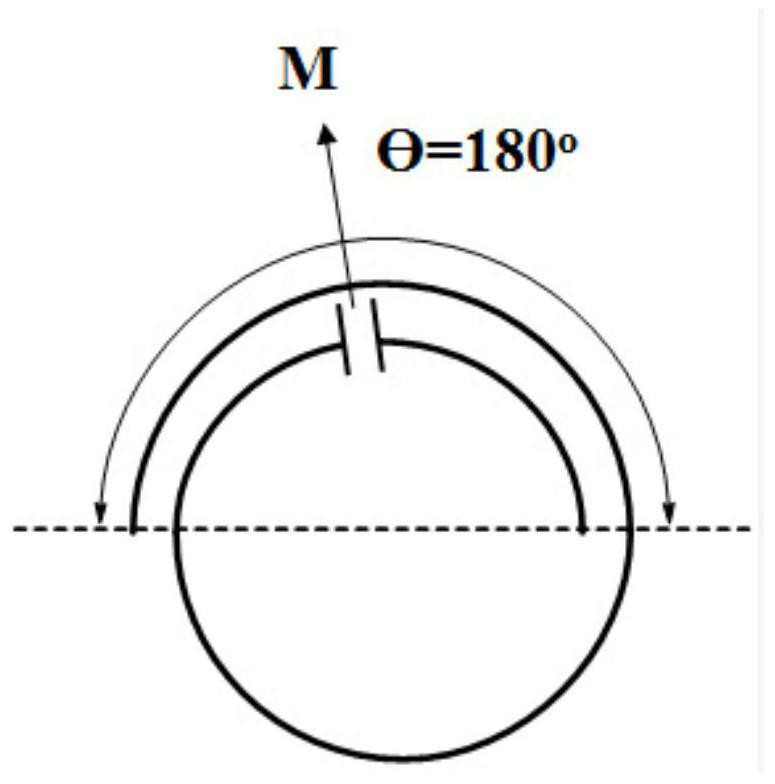

[0040] The warp yarn is composed of 4 non-thermoplastic polyimide fibers with a multifilament linear density of 1000D at constant tension, and the weft yarn is a polyetheretherketone fiber monofilament with a diameter of 0.30mm, 40 4-strand non-thermoplastic polyimide fiber yarns The thread is woven into a plain weave sheet structure in warp and weft, the weaving density of the warp yarn is 5 strands / inch, and the weaving density of the weft yarn is 20 strands / inch, while one free edge along the warp direction is woven with 2 strands of white aramid fiber for maximum use Diameter marking line, the shortest distance between the marking line and the free edge of the warp is 7mm.

[0041] The woven fabric passed through the treatment tank with a solid content of 20% by weight of anti-mold liquid successively at a speed of 5 m / min, the drying hot roller at 250°C, and the treatment tank with a solid content of 30% by weight of waterproof treatment liquid at 250 Dry the hot roll at ...

Embodiment 2

[0045] The warp yarn is composed of 3 multifilament yarns with a linear density of 1500D aramid fiber at constant tension, the weft yarn is 2 polyetheretherketone fiber monofilaments with a diameter of 0.25mm, and 40 three-strand aramid fiber yarns are woven into a plain weave sheet in warp and weft Structure, the weaving density of the warp yarn is 6 strands / inch, and the weaving density of the weft yarn is 20 strands / inch. At the same time, a free edge along the warp direction is woven with 2 strands of white aramid fiber with a maximum diameter marking line, and the marking line is free from the warp yarn. The shortest distance between sides is 9mm.

[0046] The woven fabric passed through the treatment tank with a solid content of 30% by weight anti-mold liquid successively at a speed of 6 m / min, the drying hot roll at 250°C, and the treatment tank with a solid content of 30% by weight waterproof treatment solution at 250 ℃ drying hot roll, after cooling to room temperatur...

Embodiment 3

[0050]The warp yarn is composed of 5 multifilament yarns with a linear density of 600D non-thermoplastic polyimide fibers combined at constant tension, the weft yarn is a thermoplastic polyimide fiber monofilament with a diameter of 0.35mm, and 30 3-strand non-thermoplastic polyimide fiber yarns The thread is woven into a plain weave sheet structure in warp and weft, the weaving density of the warp yarn is 10 strands / inch, and the weaving density of the weft yarn is 20 strands / inch, while one free edge along the warp direction is woven with 1 strand of white aramid fiber for maximum use Diameter marking line, the shortest distance between the marking line and the free edge of the warp is 7mm.

[0051] The woven fabric passed through the treatment tank with a solid content of 15% by weight of anti-mold liquid successively at a speed of 2 m / min, the drying hot roll at 280°C, the treatment tank with a solid content of 15% by weight of waterproof treatment liquid, 280 Dry the hot ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com