Magnesite industry energy efficiency analysis and improvement method

An energy-efficient and industry-leading technology, applied in the field of energy efficiency analysis and improvement in the magnesite industry, can solve problems such as difficult evaluation of energy-saving effects, many hidden dangers of equipment safety, and difficulties in energy-saving transformation, so as to simplify energy operation management, improve labor productivity, and reduce management pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

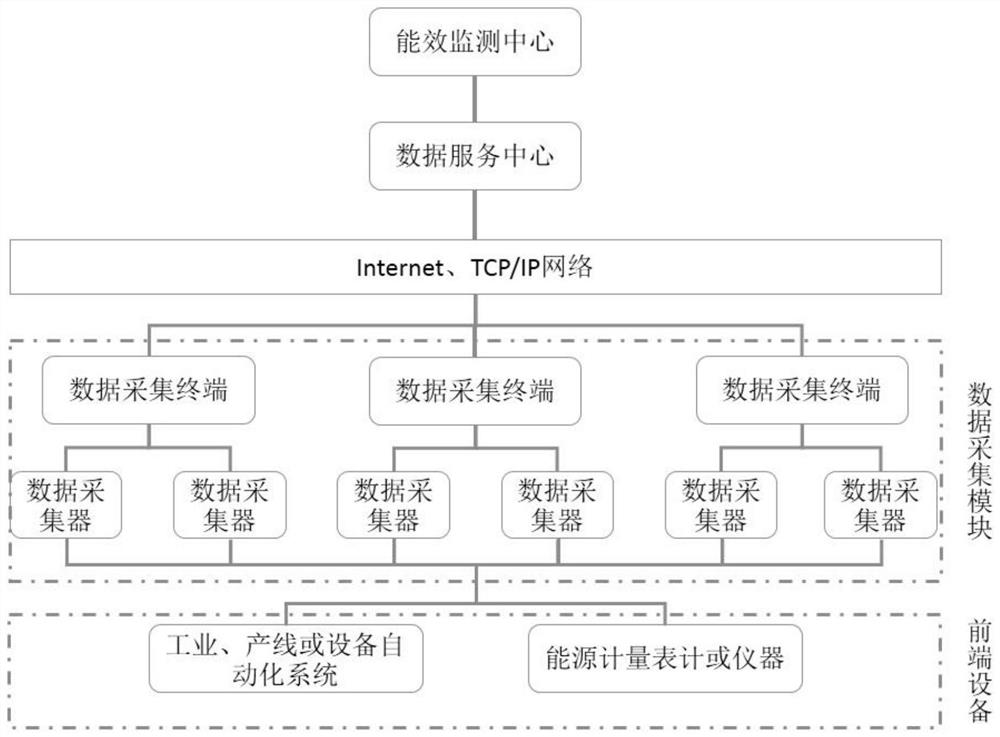

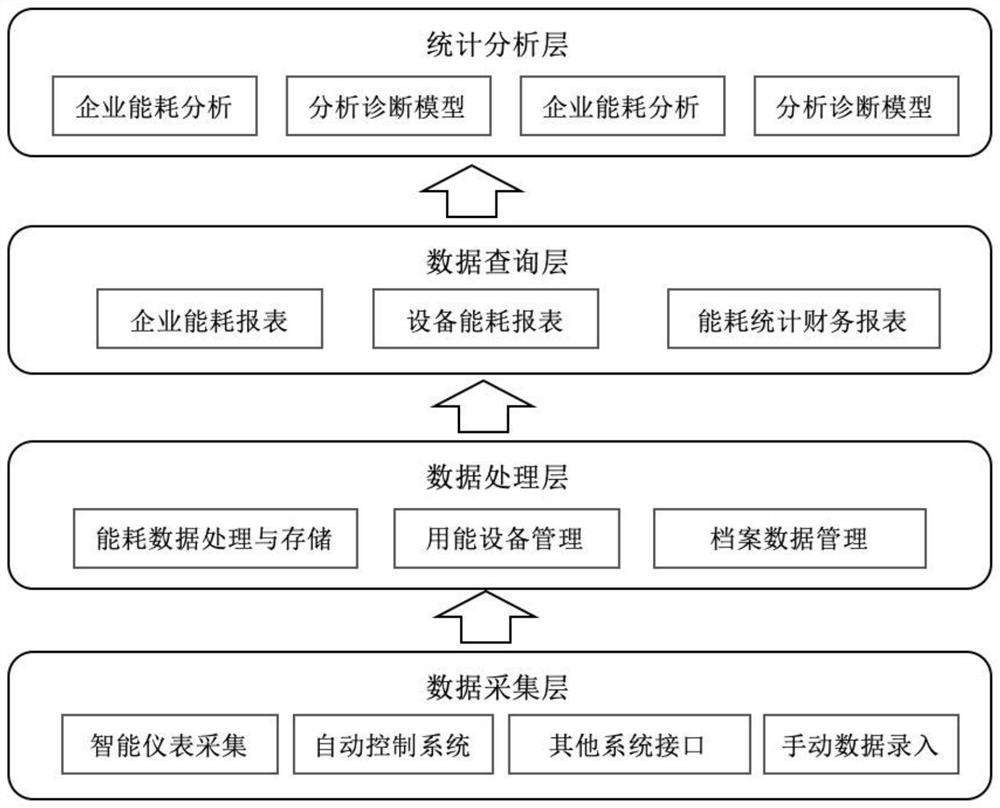

[0054] A method for analyzing and improving energy efficiency in the magnesite industry, such as figure 1 As shown, the method is realized through the following system, including: a data acquisition module, a data service center and an energy efficiency monitoring center.

[0055] The data collection module is composed of a data collector and a data collection terminal. The data collector collects energy consumption data and energy consumption quality data in the energy efficiency monitoring area, and sends the original data to the data collection terminal. The received raw data is preprocessed and uploaded to the data service center through the Internet or the enterprise private network in accordance with the specified format.

[0056] The data service center calculates, classifies, counts, files and stores the data uploaded by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com