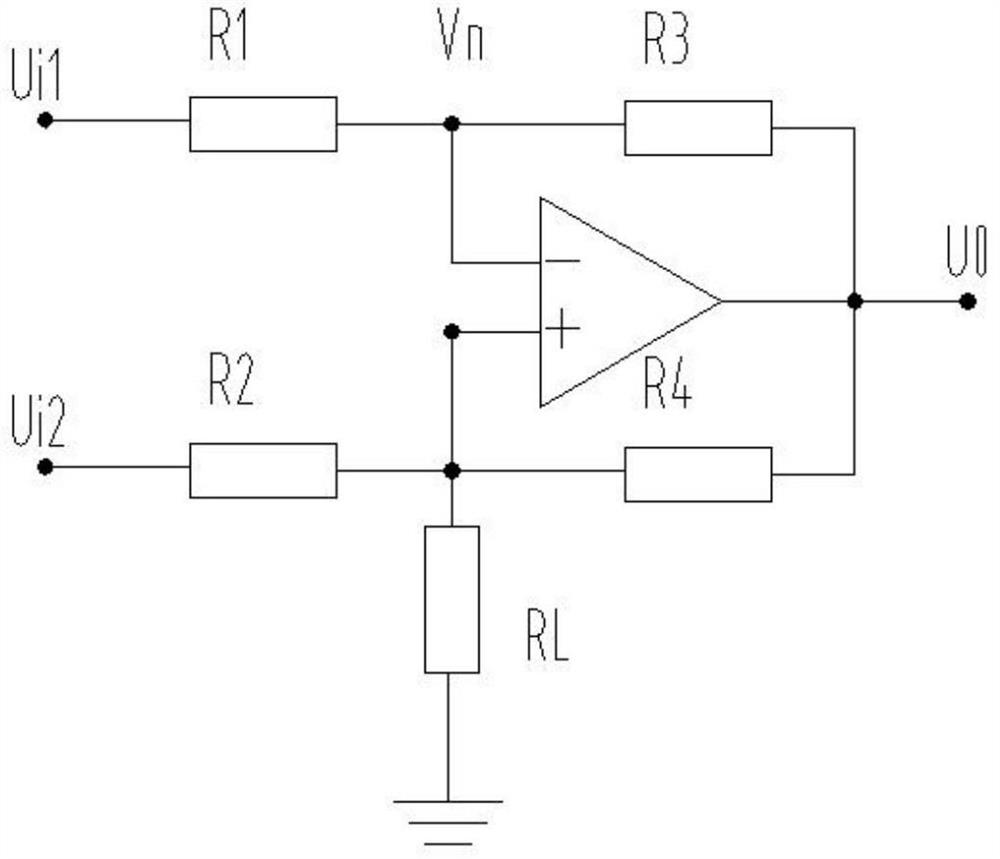

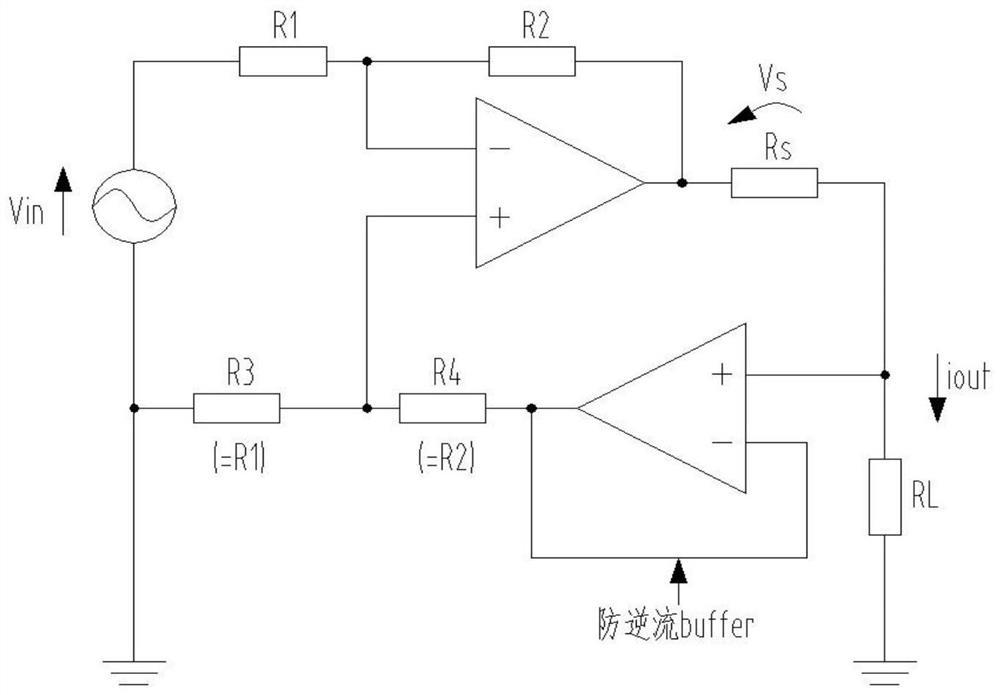

Bidirectional current source circuit

A bidirectional current and source circuit technology, applied in the field of current source, can solve the problem that single-amplitude voltage signal cannot be converted into driving signal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

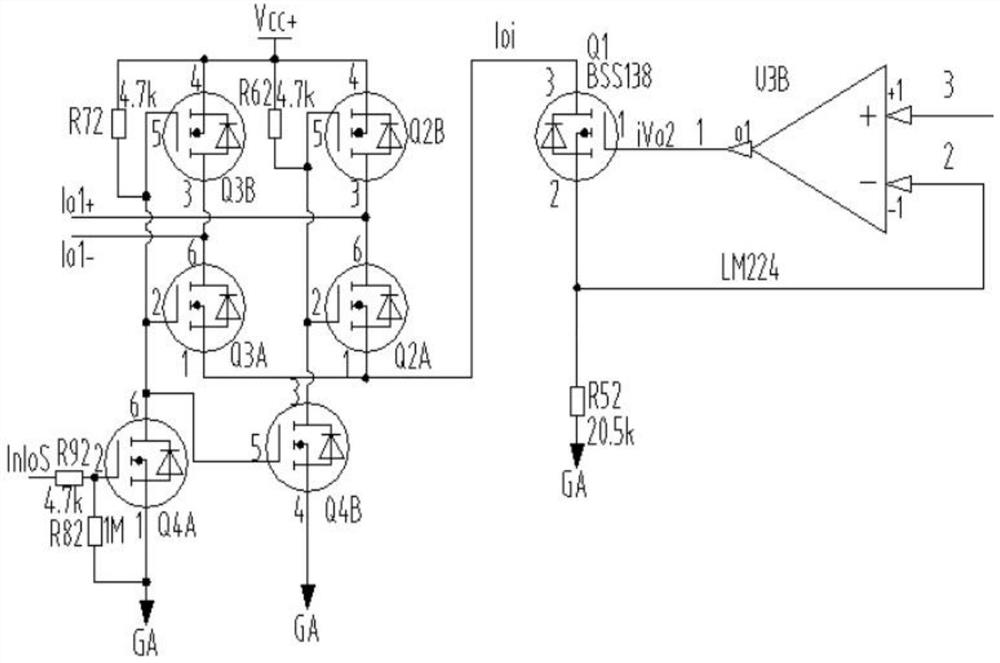

[0041] As an optional implementation manner, the second transistor bridge circuit includes:

[0042] The second PMOS transistor Q3B, the third NMOS transistor Q3A, the fourth NMOS transistor Q4A, the second resistor R72, the third resistor R82 and the fourth resistor R92, the source of the second PMOS transistor Q3B is respectively connected to the first transistor The second end of the bridge circuit is connected to one end of the second resistor R72; the gate of the second PMOS transistor Q3B is respectively connected to the other end of the second resistor R72 and the gate of the third NMOS transistor Q3A connected to the drain of the fourth NMOS transistor Q4A; the drain of the second PMOS transistor Q3B and the drain of the third NMOS transistor Q3A are the second output terminals of the bidirectional current source circuit; the third The source of the NMOS transistor Q3A is respectively connected to the first terminal of the second transistor bridge circuit and the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com