Fermented feed and preparation method thereof

A fermented feed and post-fermentation technology, applied in animal feed, animal feed, application, etc., can solve problems such as low cost and inability to utilize resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

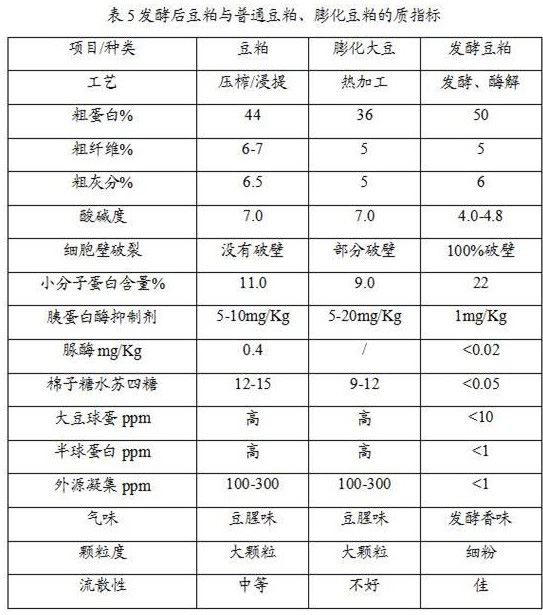

Image

Examples

Embodiment 1

[0029] Fermented feed, including the following raw materials: the residual mixture after glucosamine fermentation (the mass ratio of fermentation residue to fermentation residue is 1:5, and the content of Bacillus subtilis is 10 8 cfu / g) 200kg, corn cob 200kg, soybean meal 250kg, straw 100kg, kitchen waste 70kg;

[0030] The preparation method of above-mentioned fermented feed comprises the following steps:

[0031] (1) After the fermentation of glucosamine in the fermenter is completed, the fermenter and the corresponding pipeline are washed with tap water, and after mixing with the fermentation residue, the residual mixture after fermentation of glucosamine is obtained;

[0032] (2) Mash the kitchen waste, then mix and ferment with the residual mixture after fermentation of glucosamine, bean cake powder, corn cob, straw, kitchen waste and yeast with an inoculation amount of 0.5%, and control the temperature at At 28°C, pH is controlled at 3-8.5, mechanically turned over onc...

Embodiment 2

[0034] Fermented feed, including the following raw materials: the residual mixture after fermentation of glucosamine (the mass ratio of fermentation residue to fermentation residue is 1:6, and the content of Bacillus subtilis is 10 11 cfu / g) 200kg, corn cob 250kg, soybean meal 300kg, straw 200kg, kitchen waste 80kg;

[0035] The preparation method of above-mentioned fermented feed comprises the following steps:

[0036] (1) After the fermentation of glucosamine in the fermenter is completed, the fermenter and the corresponding pipeline are washed with tap water, and after mixing with the fermentation residue, the residual mixture after fermentation of glucosamine is obtained;

[0037] (2) Mash the kitchen waste, then mix and ferment with the residual mixture after fermentation of glucosamine, bean cake powder, corn cob, straw, kitchen waste and yeast with an inoculation amount of 0.5%, and control the temperature at 30°C, pH controlled at 3-8.5, mechanically turned over once ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com