Recycling device for autoclaved aerated concrete block cutting waste

A technology of cutting waste and autoclaving gas, which is used in the use of liquid separators, grain processing, and dispersed particle separation. , improve the quality, improve the effect of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

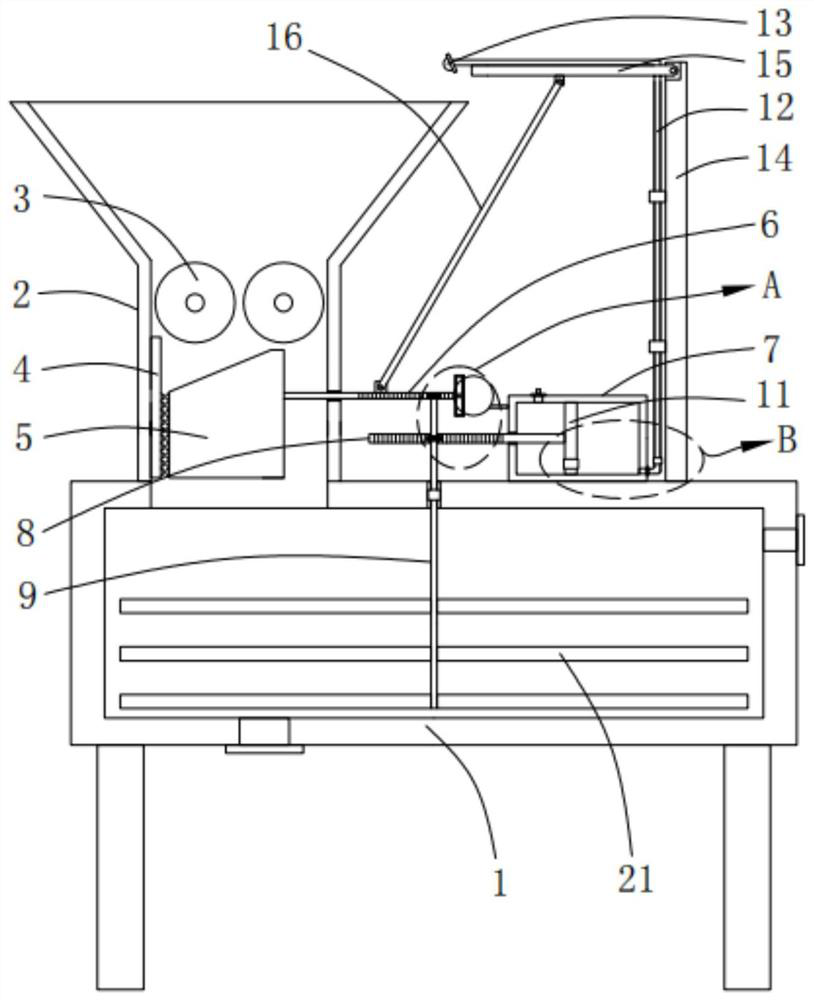

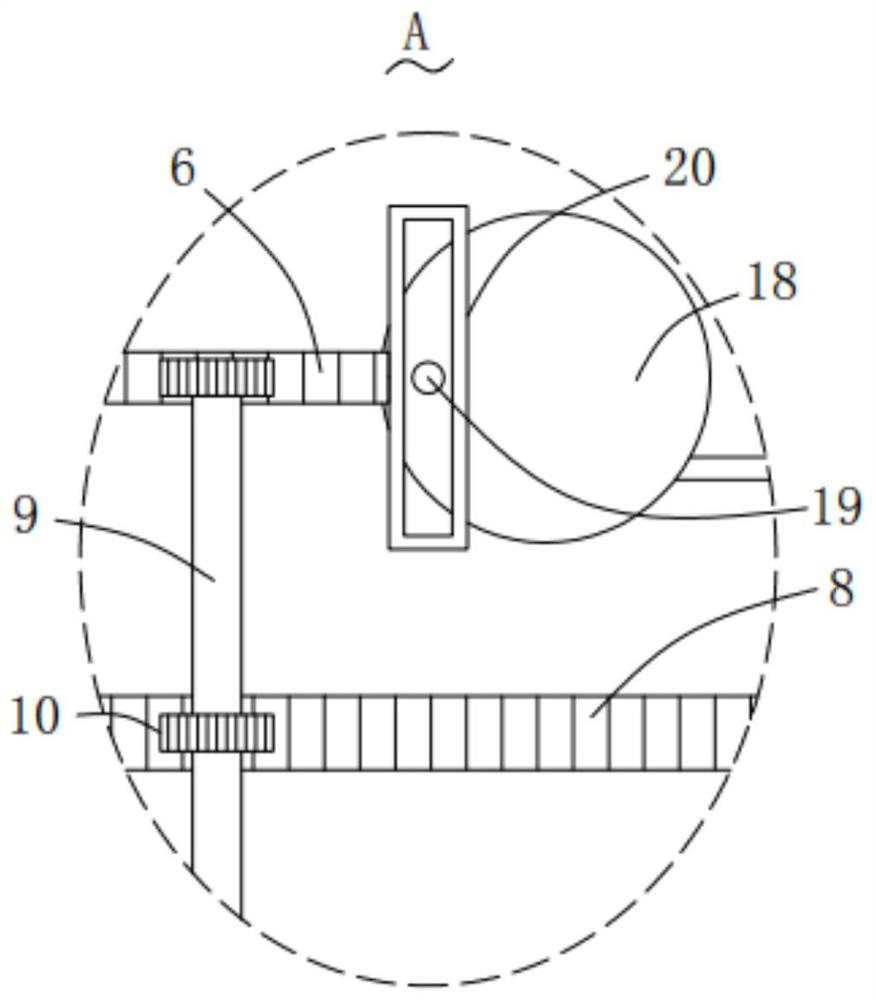

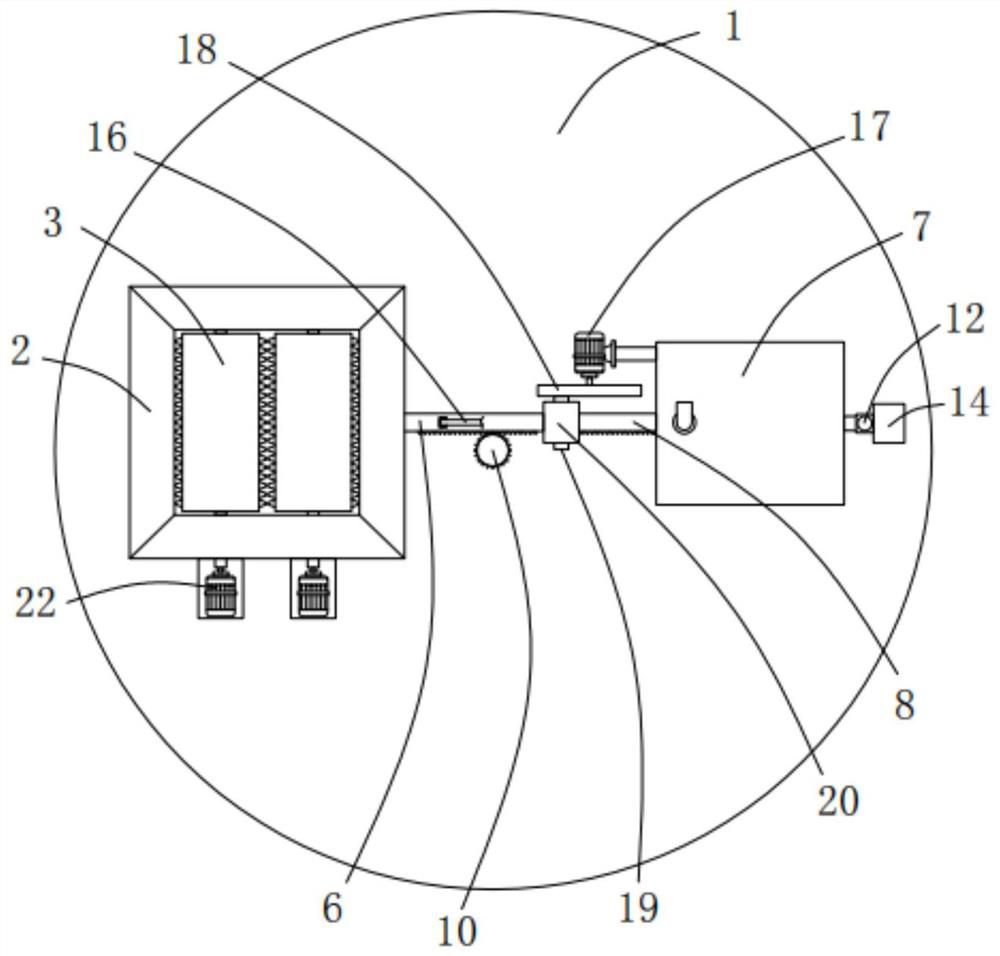

[0026] Please refer to Figure 1-6 The recycling device for autoclaved aerated concrete block cutting waste includes: a collection box 1; a feed channel 2, the feed channel 2 is fixedly installed on the top of the collection box 1, and the feed channel 2 is connected to the top of the collection box 1 The collection box 1 is connected; two crushing rollers 3 are symmetrically rotated and installed in the feed channel 2; a first crushing plate 4 is fixedly installed in the On the inner wall of the feed channel 2; the second crushing plate 5, the second crushing plate 5 is slidably installed in the feed channel 2, and the second crushing plate 5 is suitable for the first crushing plate 4 Matching; the first gear rod 6, the first gear rod 6 is installed in the feed channel 2 in a sliding seal, one end of the first gear rod 6 is fixedly connected with the second crushing plate 5, and the The other end of the first gear rod 6 runs through the feed channel 2; the cylinder body 7, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com