Bidirectional reversible fine crusher capable of conveniently adjusting particle size of crushed materials

A fine crusher and material technology, applied in the direction of grain processing, etc., to achieve the effect of breaking material arching, improving uniformity, and meeting the requirements of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

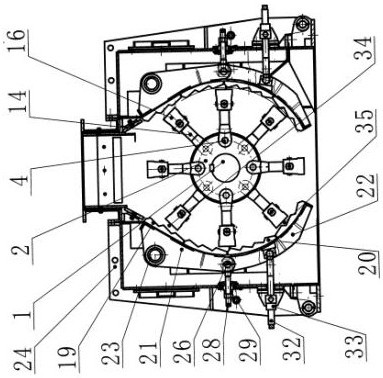

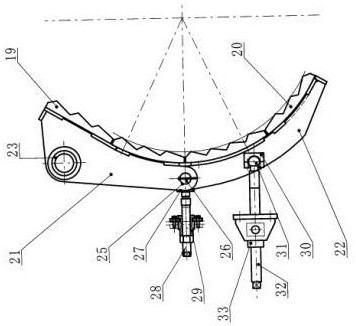

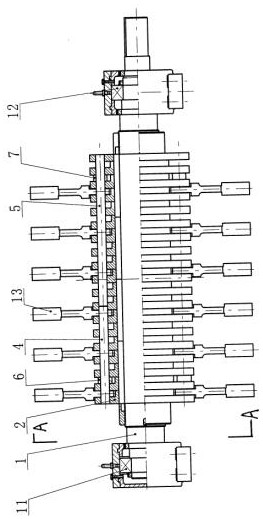

[0023] The present invention is described in detail below in conjunction with accompanying drawing:

[0024]A two-way reversible fine crusher for conveniently adjusting the particle size of the crushed material, comprising a fine crusher shell 24, at the upper end of the fine crusher shell 24, a crushing material inlet is arranged, and at the lower end of the fine crusher shell 24, a crushing The material outlet, in the fine crusher shell 24 between the crushed material inlet and the crushed material outlet, is provided with a box-shaped cavity for crushed materials, and two crushing plates are symmetrically arranged in the box-shaped cavity , A rotor main shaft 1 is arranged between the two crushing plates, and hammer discs 2 are thermally installed on the rotor main shaft 1 at equal intervals. A hammer shaft is connected through the through hole 3, and a hammer head assembly 13 is connected to the hammer shaft. The crushing plate is composed of an upper arc-shaped crushing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com