Fuel gas pressure regulating box

A technology for gas pressure regulation and gas pressure regulator, which is used in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc. The seat tightness detection is accurate, the displayed value is stable, and the service life is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

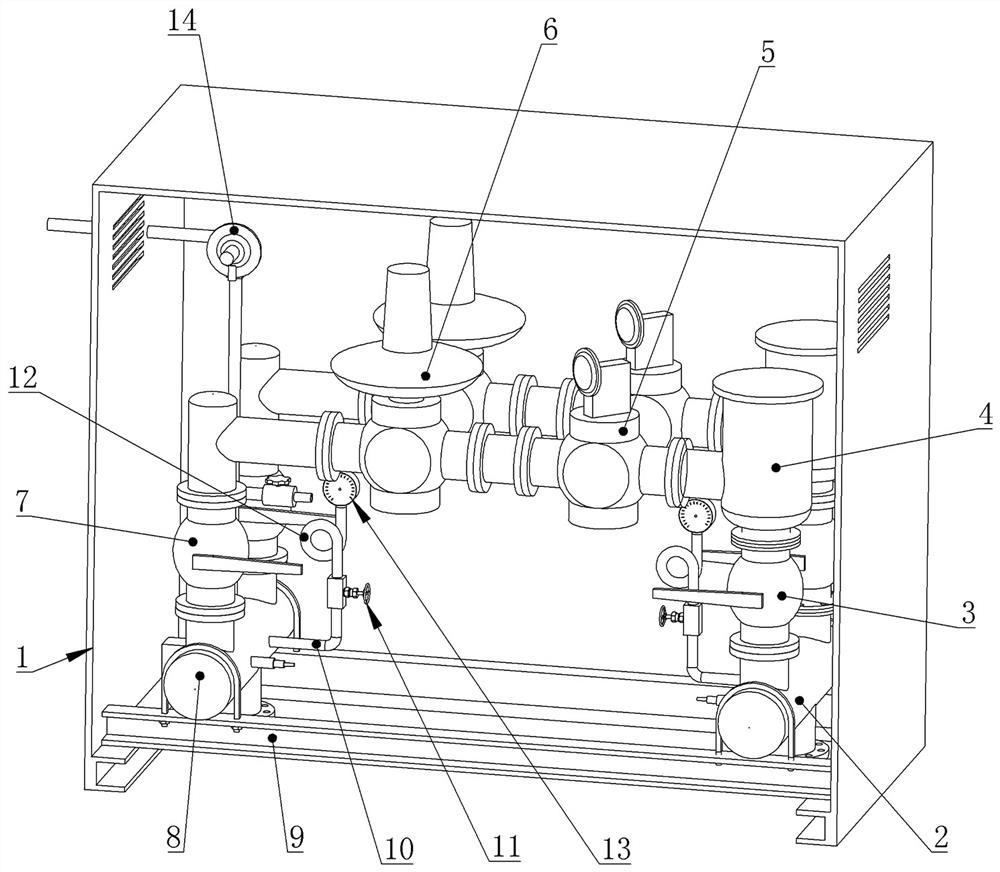

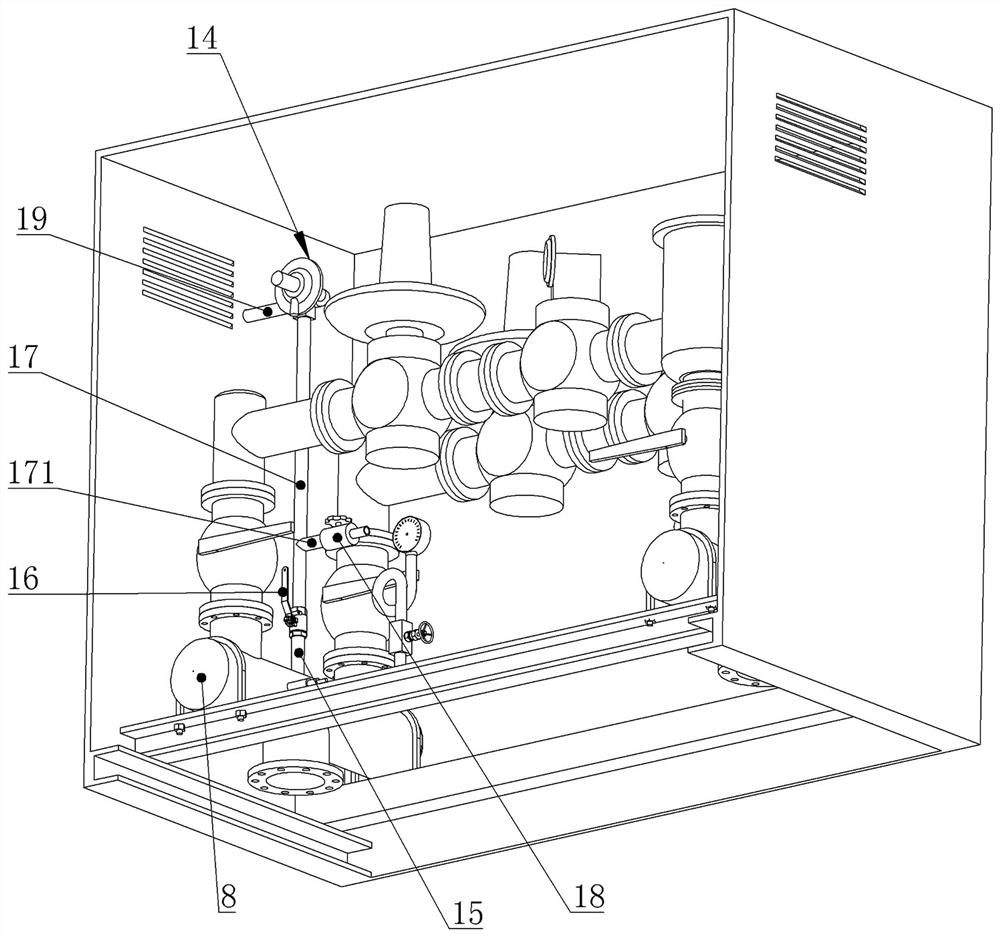

[0017] Combine Figure 1-2 As shown, a gas pressure regulator comprising a casing 1, and an inlet tube 2 is provided inside the casing 1, and the lower portion of the inlet tube 2 is used to connect the gas intake pipe, the upper portion of the inlet tube 2 The inlet ball valve 3 is connected to the upper portion of the inlet ball valve 3, and the outlet of the filter 4 is connected to a gas pressure regulator 6 through a line, and the exit of the gas regulator 6 is connected to the outlet ball valve 7 through a pipe. The other end of the outlet ball valve 7 is connected to an outlet tube 8, and the lower portion of the outlet tube 8 is used to connect the gas vent. One side of the outlet tube 8 is provided with a pressure regulating tube 10, and the pressure tube 10 is connected to a needle valve 11, and the needle valve 11 has a pressure table 13 through a pipeline, and the pressure Table 13 is micro. The stamp, the range is 0-16 kPa, and the needle valve 11 is provided with a bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com