Storage tank bottom plate welding line vacuum test apparatus

A vacuum test and storage tank bottom plate technology, applied in the direction of using liquid/vacuum degree to measure liquid tightness, and detecting the appearance of fluid at the leakage point, etc., can solve the problem that the welding seam detection method is not rigorous and cannot meet the requirements of construction specifications , Affecting the construction quality of storage tanks and other issues, to achieve the effect of simple structure, improving the progress of vacuum leak detection and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

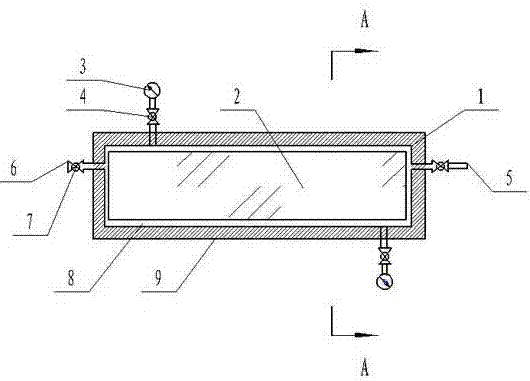

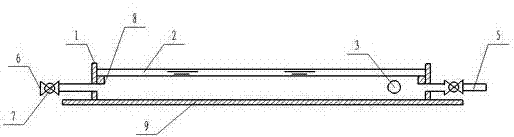

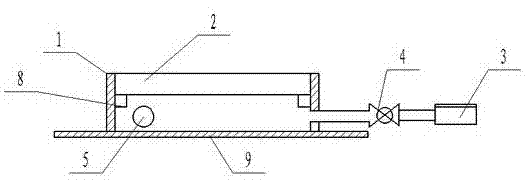

[0015] A storage tank bottom plate weld vacuum test device, comprising a frame body 1, the shape of the frame body 1 is a cuboid, characterized in that the top and bottom of the frame body 1 are provided with openings, and the top of the frame body is provided with Observation window 2, the two long sides of the frame body 1 are provided with vacuum pressure gauges 3, the two vacuum pressure gauges 3 are arranged diagonally, and two vacuum pressure gauges 3 with the same range can be installed on the diagonal for verification. At the same time, the air pressure change in the frame can be accurately observed in real time during the vacuuming process. Before the vacuum pressure gauge, a control valve I4 is installed, and the two short sides of the frame are respectively provided with a vacuum pump interface 5 and an air inlet 6. Both the vacuum p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com