Blast furnace cooling equipment leak detection device

A technology for cooling equipment and blast furnaces, which is applied in the direction of cooling devices, etc., can solve the problems that the ignition method is not easy to ignite, and achieve the effect of simple structure and convenient portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

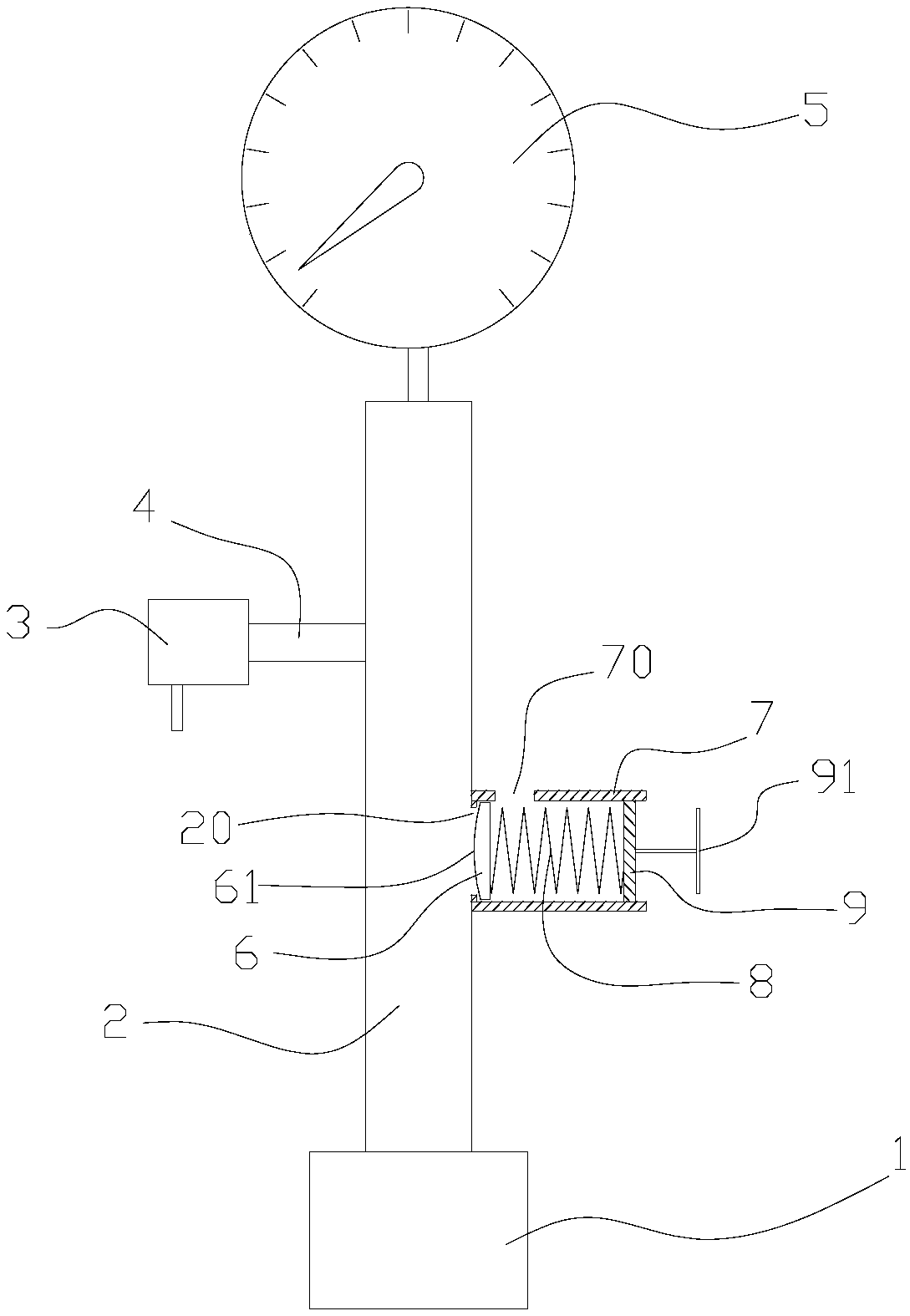

[0021] Such as figure 1 As shown, the embodiment of the present invention includes a joint 1 , a water pipe 2 , a valve 3 , a short connection 4 , a pressure gauge 5 , a cover plate 6 , a drain cylinder 7 , a spring 8 , and a sealing plate 9 .

[0022] Specifically, the joint 1 is used to connect to the cooling water pipeline of the blast furnace cooling equipment. Preferably, the joint 1 is a quick joint. Generally speaking, the blast furnace cooling equipment has a water inlet valve and a water outlet valve, and a three-way valve is installed between the water inlet valve and the cooling equipment to switch between soft water and industrial water. When checking whether a cooling device is damaged, the joint 1 of this embodiment is connected to the three-way valve for leak checking. The size of the joint 1 is selected according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com