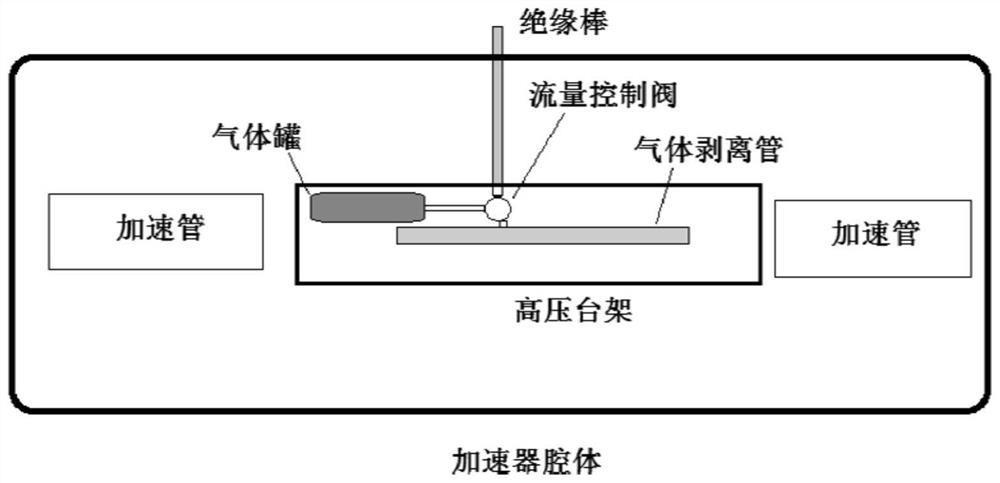

Small serial accelerator stripping gas input device

A technology of stripping gas and input device, applied in the direction of electrical components, accelerators, etc., can solve the problems of inconvenient operation, large volume of high-voltage bench, unfavorable miniaturization, etc., achieve compact structure, save floor space and equipment cost, improve Effects of stability and runtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

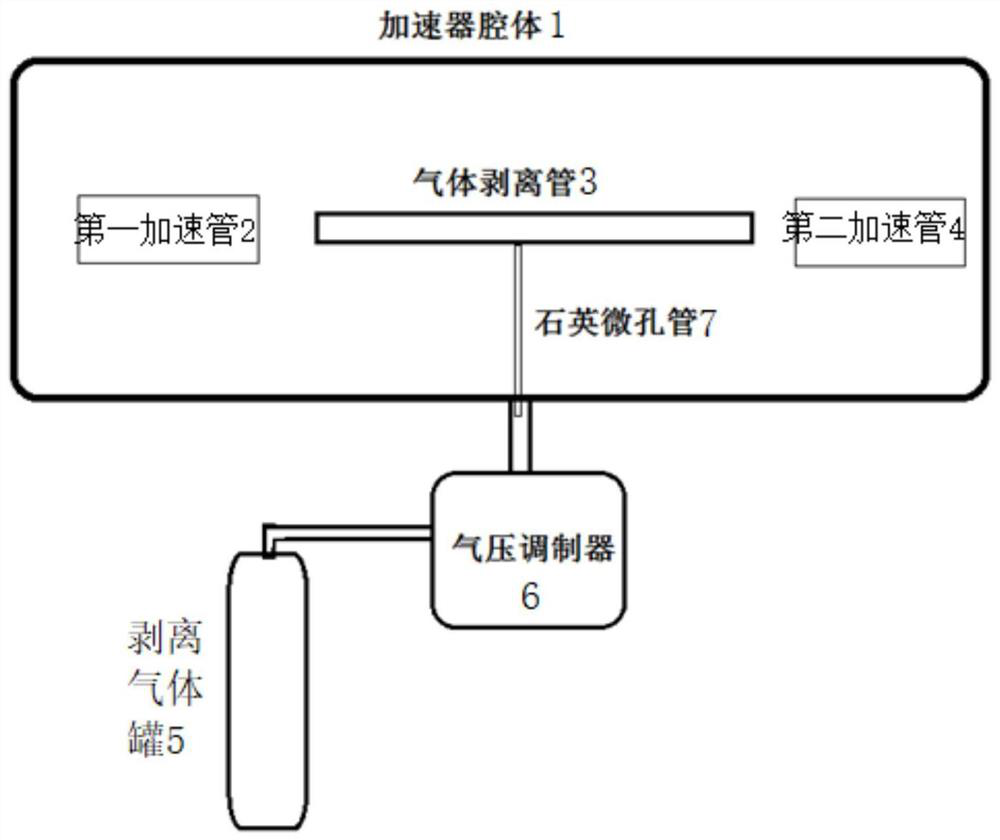

[0018] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0019] figure 2 It shows a schematic structural view of a small tandem accelerator stripping gas input device provided in the specific embodiment of the present invention. As can be seen from the figure, the device includes an accelerator cavity 1, and the inside of the accelerator cavity 1 is along the length of the accelerator cavity. The first accelerating tube 2, the gas stripping tube 3 and the second accelerating tube 4 are arranged in sequence in the direction, and the accelerator cavity 1 is provided with a stripping gas tank 5 and an air pressure modulator 6, and one end of the air pressure modulator 6 communicates with the stripping gas tank 5, The other end communicates with the quartz microporous tube 7 inside the accelerator cavity, and the other end of the quartz microporous tube 7 communicates with the gas stripping tube 3 . The de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com