Spinning machine cradle and pressure fine adjustment method

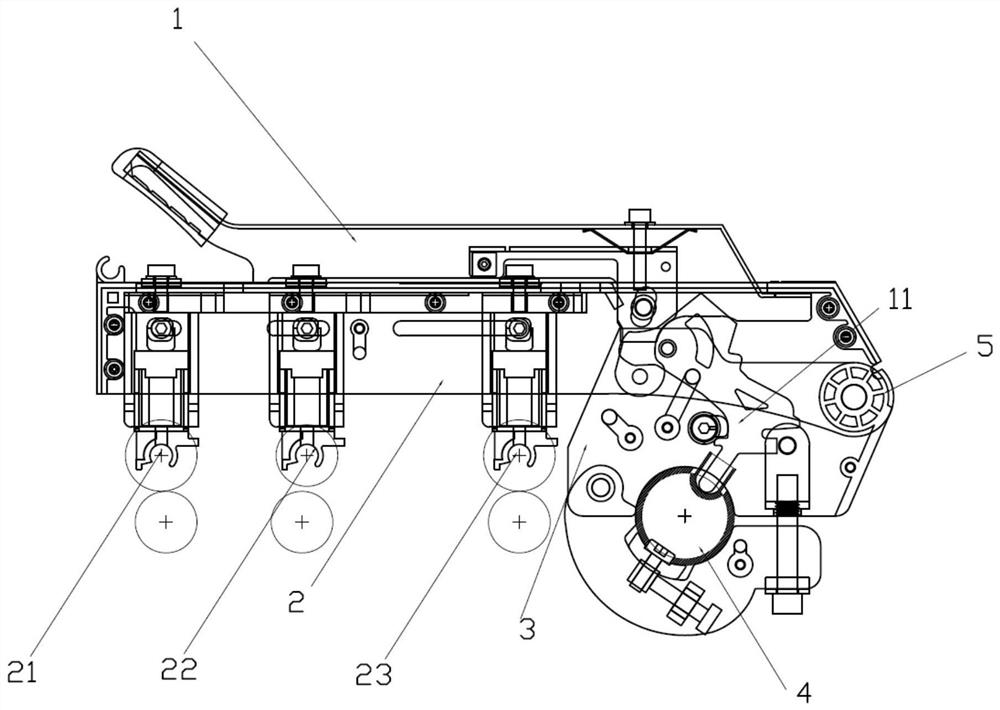

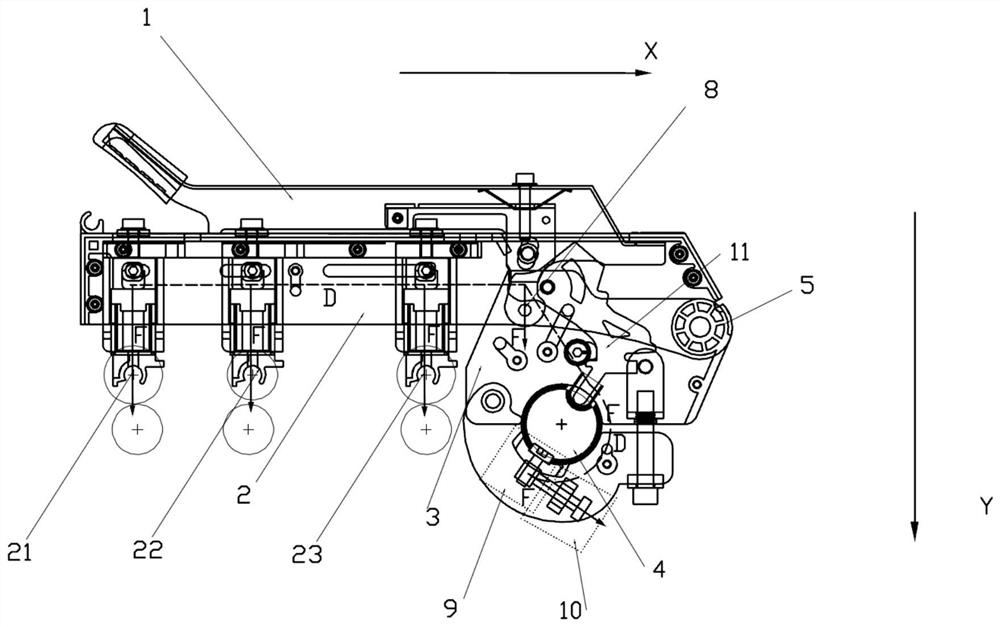

A technology for spinning machines and cradles, which is applied to spinning machines, textiles, papermaking, and drafting equipment. The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 8

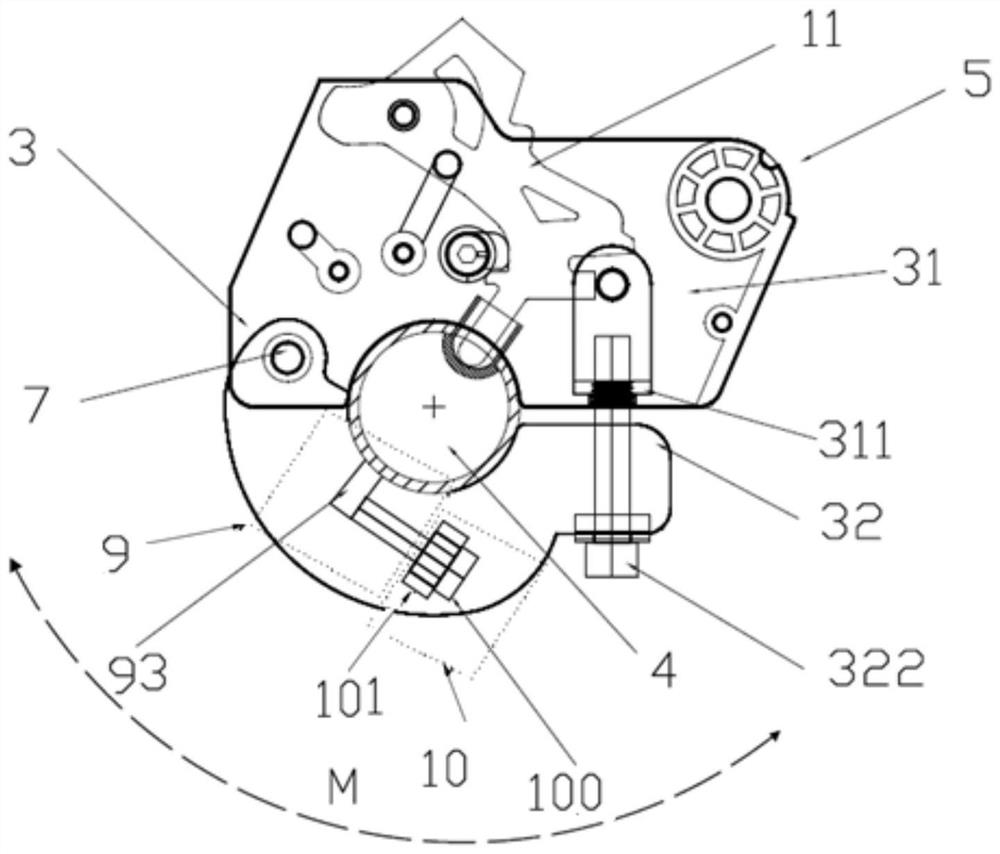

[0049] Embodiment eight, such as Figure 11a As shown, the limiting part 93 of the limiting component 9 is a square steel block, and the adjusting part 100 is a round head hexagon socket head cap bolt. The head of the adjusting part 100 abuts against the side of the limiting part 93 , and when the adjusting part 100 is rotated, the force exerted by the head on the pressure receiving surface of the limiting part 93 changes. The head of the adjustment part 100 is arc-shaped, and it is not easy to produce indentation when pressed, and the accuracy of the pressure value adjusted each time can still be maintained for a long time. This scheme is simple in structure, easy to operate, reliable and effective.

Embodiment 9

[0050] Embodiment nine, such as Figure 11b As shown, taking the intersection point of the extension line of the central axis of the adjusting part 100 and the side of the limiting part 93 as the axis, in the moving direction of the adjusting part 100, a threaded through hole 94 is opened in the limiting part 93, that is, the limiting part 93. Bit pass slot. The adjustment part 100 matches with the threaded through hole 94 . In this embodiment, the adjustment part 100 uses M6 inner hexagonal bolts, and when they are transferred into or out of the threaded through hole 94, through the interaction between the threads, the limit part 93 generates a pushing or pulling force, thereby regulating the pressure. The component 10 can move forward and backward in both directions relative to the limit component 9, correspondingly, the cradle seat 3 can be adjusted to realize pressurization and pressure release, and the adjustment range of the pressure value of this solution is due to the...

Embodiment 10

[0051] Embodiment ten, such as Figure 11c As shown, the difference from Embodiment 9 is that the two opposite inner walls of the lower fixing card 32 are arranged with arc-shaped grooves 102, and the assembly part 101 is limited to slide in the arc-shaped grooves 102; , through the interaction between the screw threads, a pushing or pulling force is generated on the limiting portion 93 . Since the assembly part 101 can slide in the arc-shaped groove 102, the displacement direction of the adjustment part 100 to the limit part 93 can be kept tangent to the circumferential direction of the cradle rod shaft 4. In addition, the adjustment part 100 can maintain good rigidity after long-term use , the resulting change in the pressure value of the cradle is more continuous and stable, with better consistency, and can avoid adjustment deviation to the greatest extent.

[0052] The above-mentioned embodiment can achieve the expected technical effect of the present invention, has a sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com