Modular mobile plant for the production of fluid self-compacting soils

A technology of self-compacting and solidifying soil, which is applied in the direction of clay preparation equipment, chemical instruments and methods, mixing operation control, etc. It can solve the problems of being easily restricted by transport vehicles and transport roads, poor flexibility, rigid connections, etc., and achieve good continuity Operational performance and reliability, ease of transfer and installation, and flexible installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

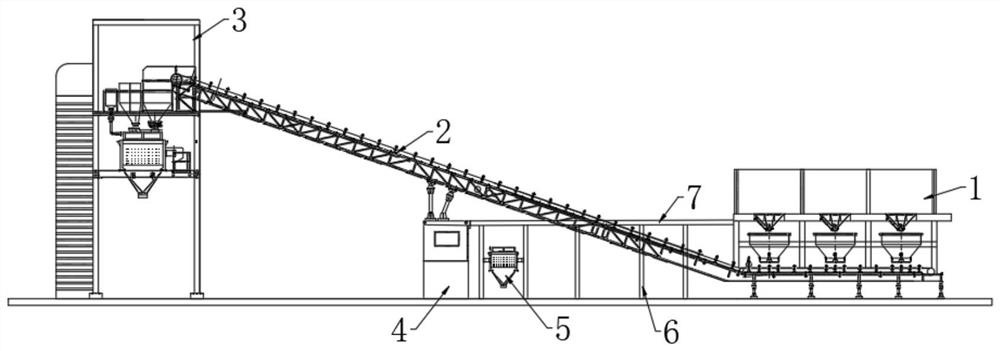

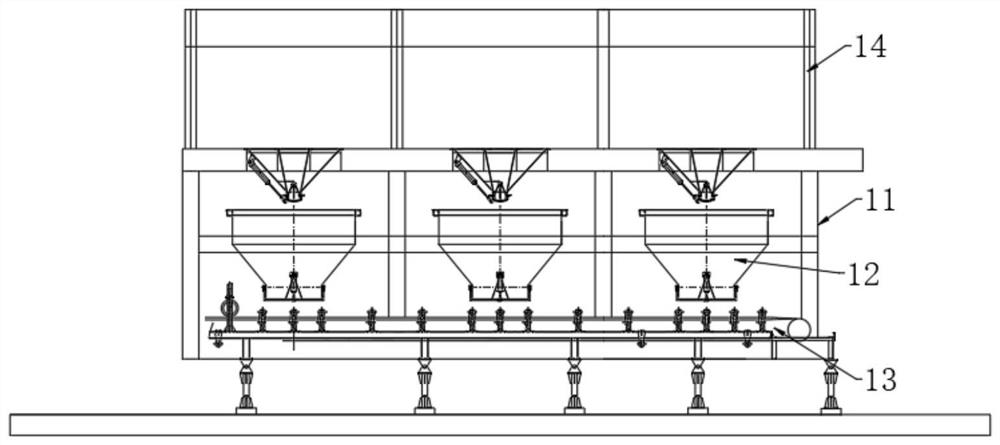

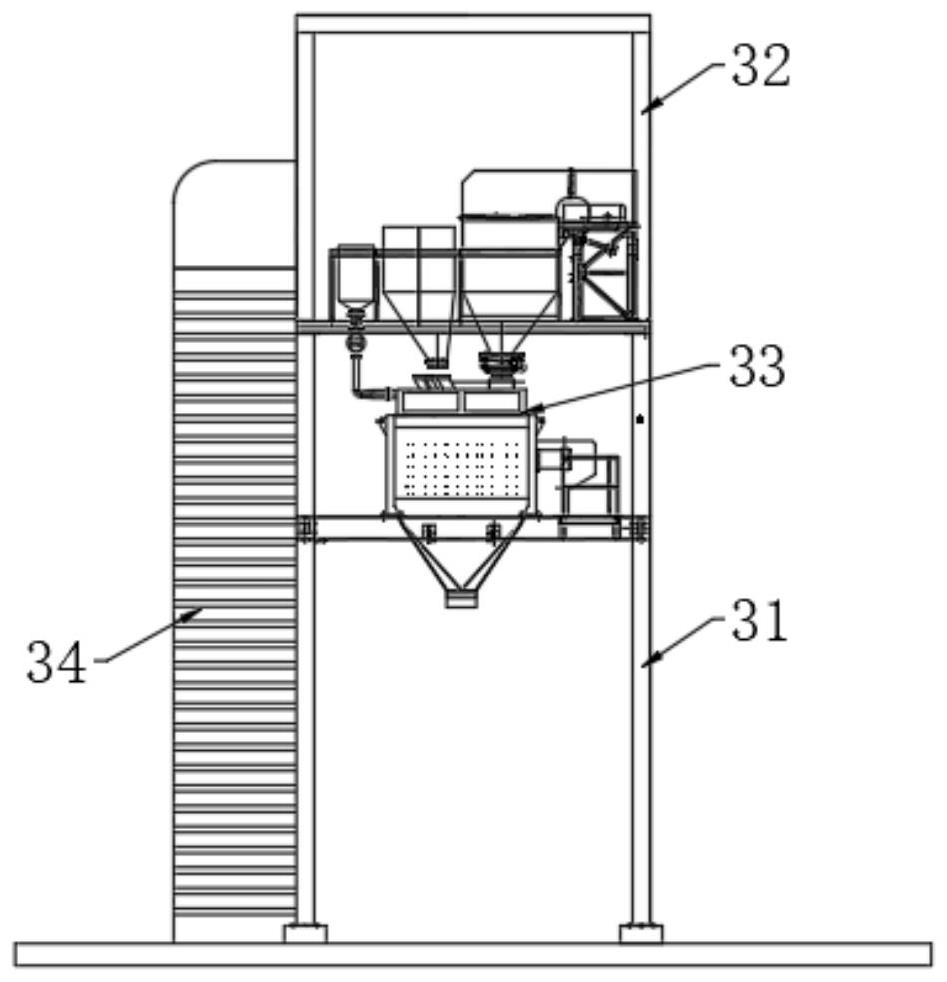

[0035] refer to Figure 1-14 , the present embodiment proposes a modular mobile device for producing fluid self-compacting solidified soil, including a batching assembly 1, a feeding assembly 2 and a mixing assembly 3, and the batching assembly 1 includes a support one 11, on which the support one 11 There are three batching machines 12 and conveying equipment 13 in a linear distribution, the conveying equipment 13 is located below the three batching machines 12, two side baffles 14 are fixedly installed on the top of the bracket one 11, and the mixing assembly 3 includes a fixed connection Together with the support two 31 and the main mixing building 32, the mixing hopper 33 is installed on the main mixing building 32, the control assembly 4 and the high-speed pulping machine 5 are arranged between the batching assembly 1 and the mixing assembly 3, and the feeding assembly 2 is movably installed in the control The top of the component 4, and the feeding component 2 is oblique...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com