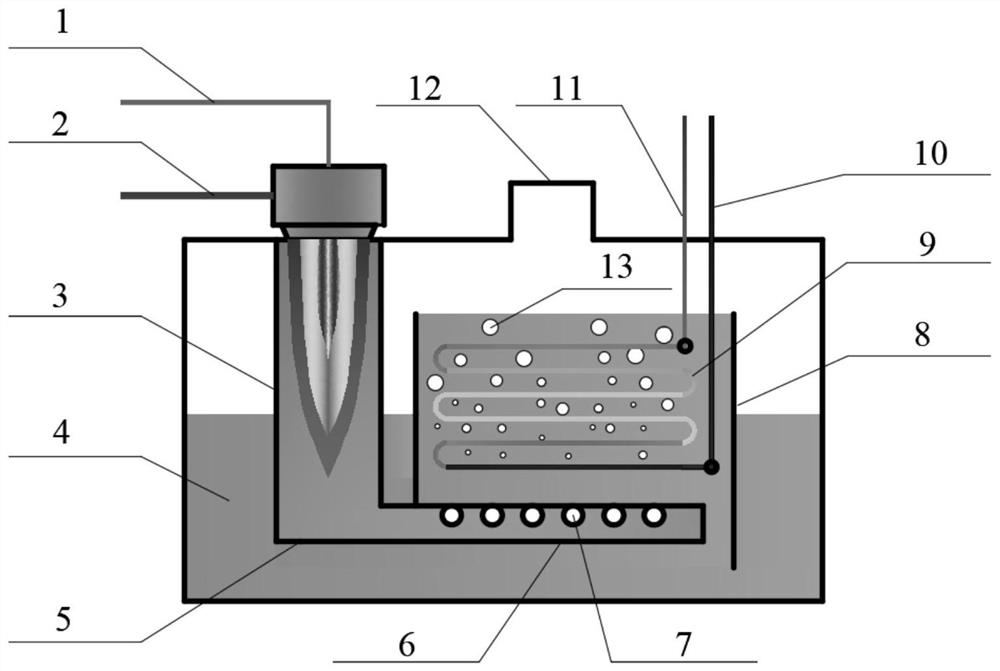

A Method for Predicting and Measuring Ice Layer in Heat Transfer Tubes of Submerged Combustion Gasifier

A technology of immersion combustion and measurement method, applied in the field of LNG vaporizer, can solve the problems of difficult prediction of heat exchange performance between LNG and water bath, icing, ice layer formation position and thickness cannot be directly observed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

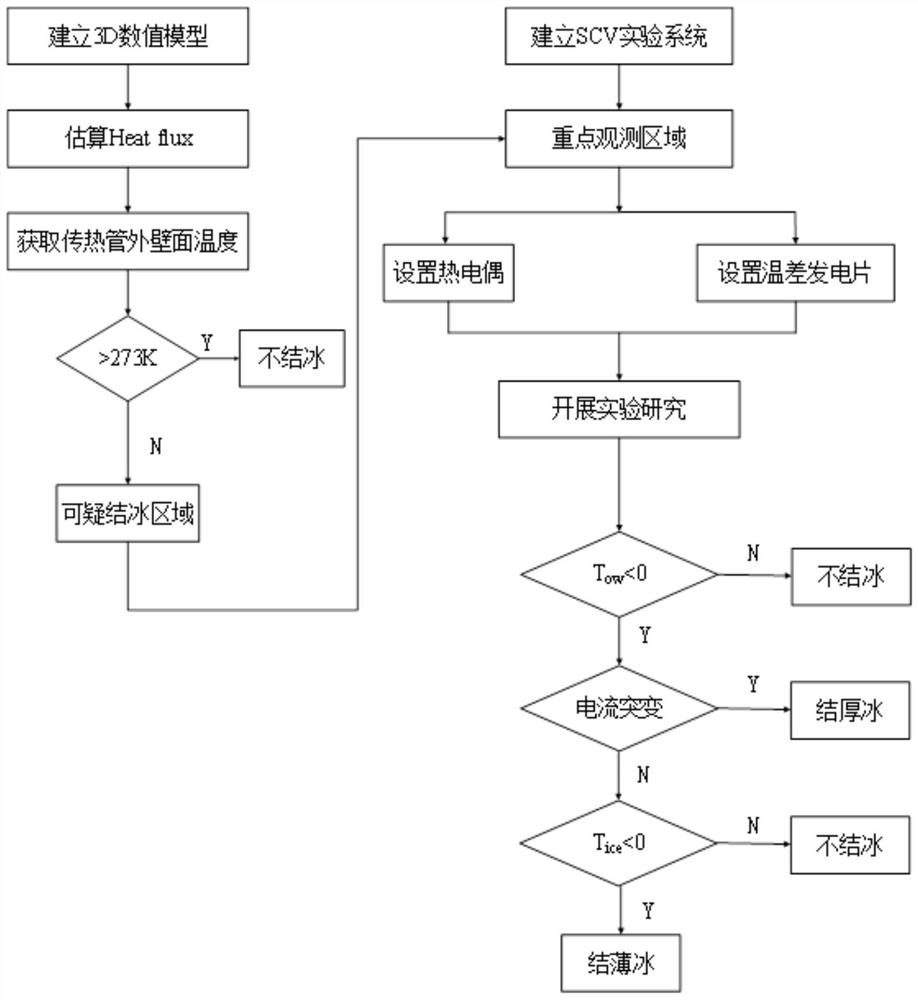

[0040]

[0042] When T

[0043]

[0044]

[0046] When T

[0047] When T

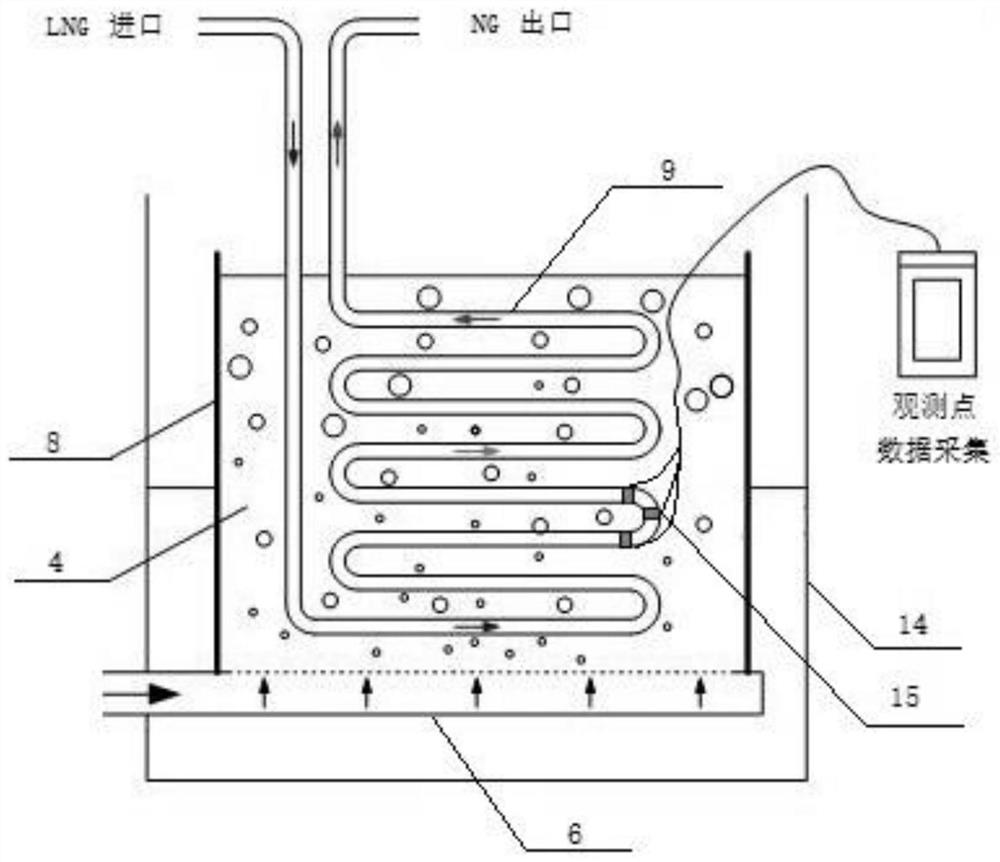

[0052] (1) Measure the temperature of the outer wall surface of the heat transfer tube (equivalent to the inner wall surface of the thermoelectric power generation sheet) with a thermocouple. Since the thermocouple returns

[0055]

[0058]

[0060]

[0061] The thickness of the ice layer can thus be calculated from the fundamental equation of heat transfer.

[0062]

[0064] While embodiments of the present invention have been shown and described above, it is to be understood that the above-described embodiments are examples

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com