Nitrogen dioxide sensor based on two-dimensional molybdenum disulfide nano material

A molybdenum disulfide, nitrogen dioxide technology, applied in the analysis of materials, material resistance, material analysis by electromagnetic means, etc., can solve the problems of limited application, difficult detection, complex process and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

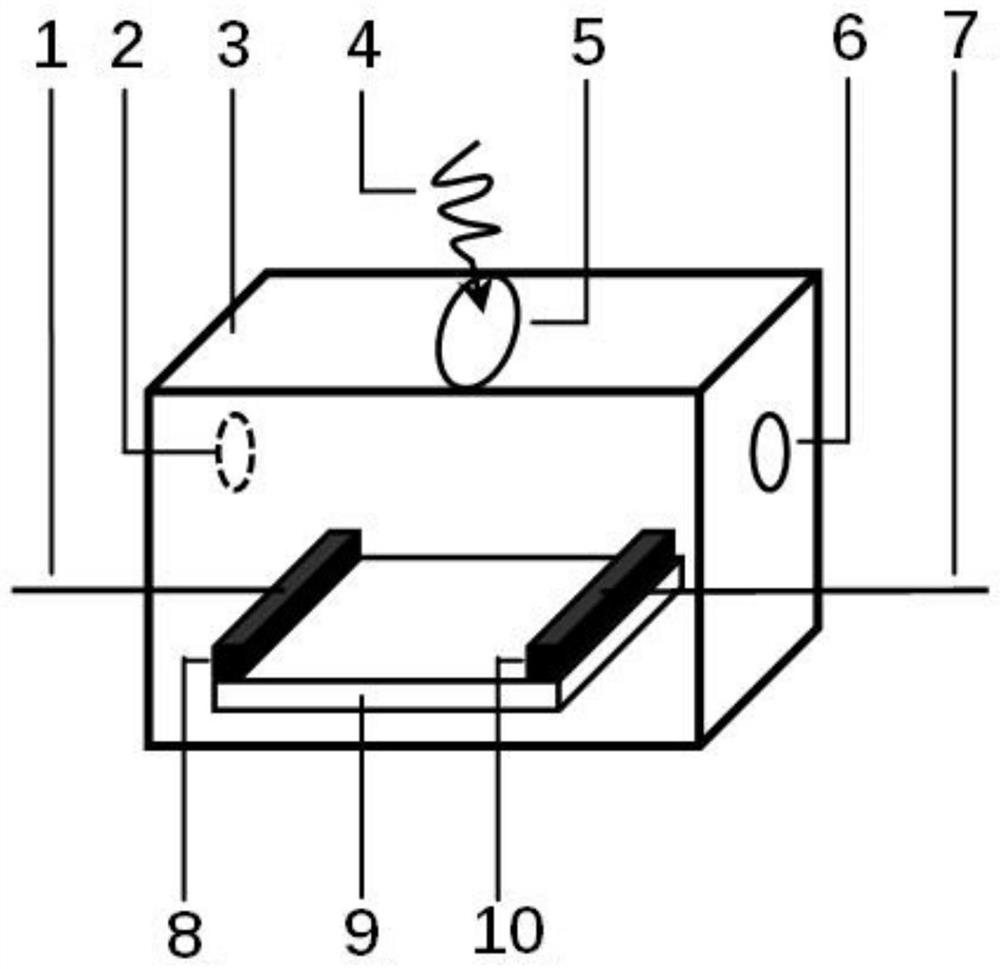

[0020] as attached figure 1 As shown, the nitrogen dioxide sensor based on two-dimensional molybdenum disulfide nanomaterials of the present invention uses molybdenum disulfide material as the sensing material and arranges source and drain on both sides thereof, and on the source and drain respectively The source lead and the drain lead are set and placed in the reaction chamber; the gas input channel and the gas output channel are set on both sides of the sensor, and the ultraviolet filter is embedded on the wall of the sensor above the molybdenum disulfide material, so that the ultraviolet light is irradiated on the Molybdenum disulfide material. The overall size of the sensor (that is, the reaction chamber) is 3×3×2mm 3 The two-dimensional nanomaterial molybdenum disulfide (MoS2) is purchased from Shanghai Xianfeng Nano Technology Co., Ltd. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com