Optical method for measuring resistivity of silicon wafer in non-contact manner

A non-contact, optical method technology, applied in the direction of measuring resistance/reactance/impedance, measuring electrical variables, measuring devices, etc., can solve the problem of inability to do full-coverage scanning measurement of large-size wafers and the inability to measure wafer resistance Rate and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

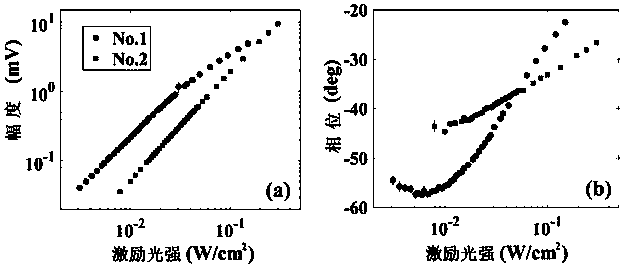

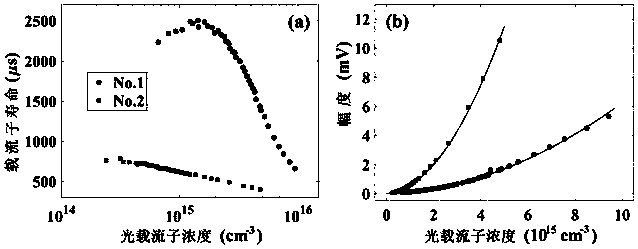

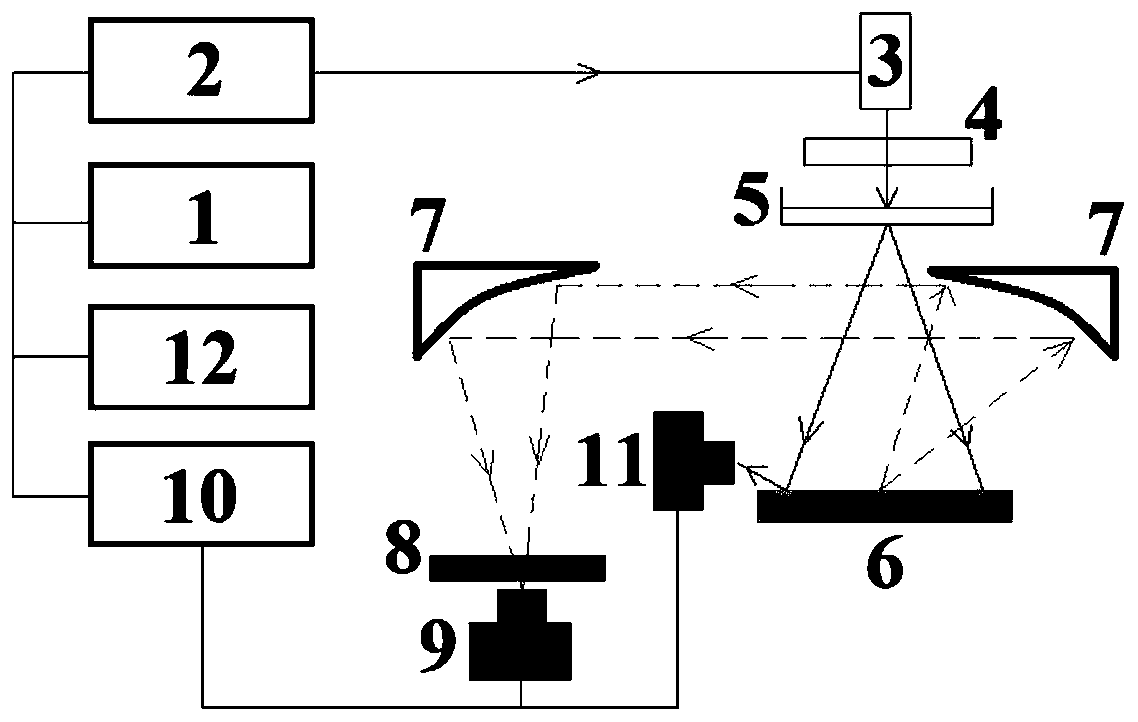

[0021] Combine below Figure 1-3 A non-contact optical method for measuring the resistivity of a silicon wafer proposed by the present invention is specifically described. However, it should be understood that the accompanying drawings are only provided for better understanding of the present invention, and should not be construed as limiting the present invention. The specific implementation steps are as follows:

[0022] (1) Build the experimental system. build as figure 1 The optical experimental system for the non-contact measurement of silicon wafer resistivity shown includes a function generator 1, an excitation laser 2, a beam collimator 3, an adjustable neutral filter 4, a uniform beam expander 5, and an off-axis parabola Mirror 7, long pass filter 8, two photodetectors 9 and 11, lock-in amplifier 10, computer 12.

[0023] a. Connect the function generator to the laser, and set the safe range of the output signal amplitude of the function generator based on the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com