Spindle protection device capable of avoiding transverse inclination and reducing vibration

A protection device, lateral tilting technology, applied in the direction of spring/shock absorber, vibration suppression adjustment, rotational vibration suppression, etc., can solve problems such as noise pollution, and achieve the effect of avoiding noise pollution, reducing noise, and improving equipment stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

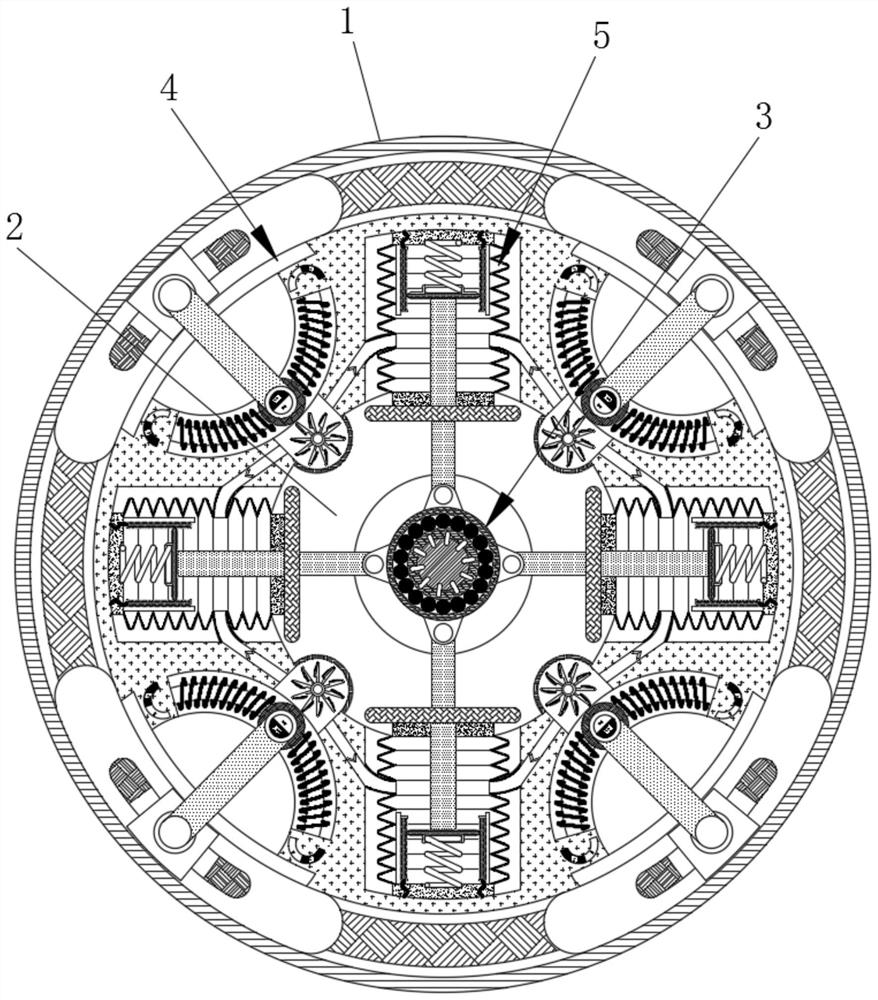

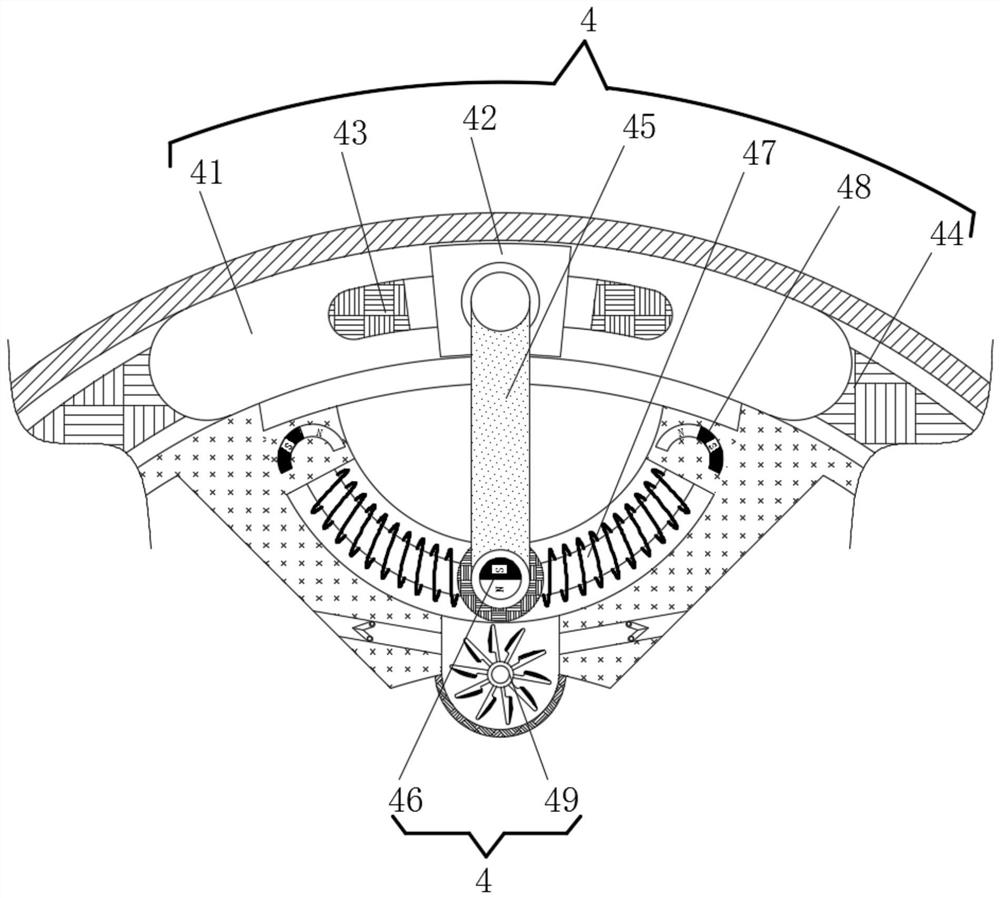

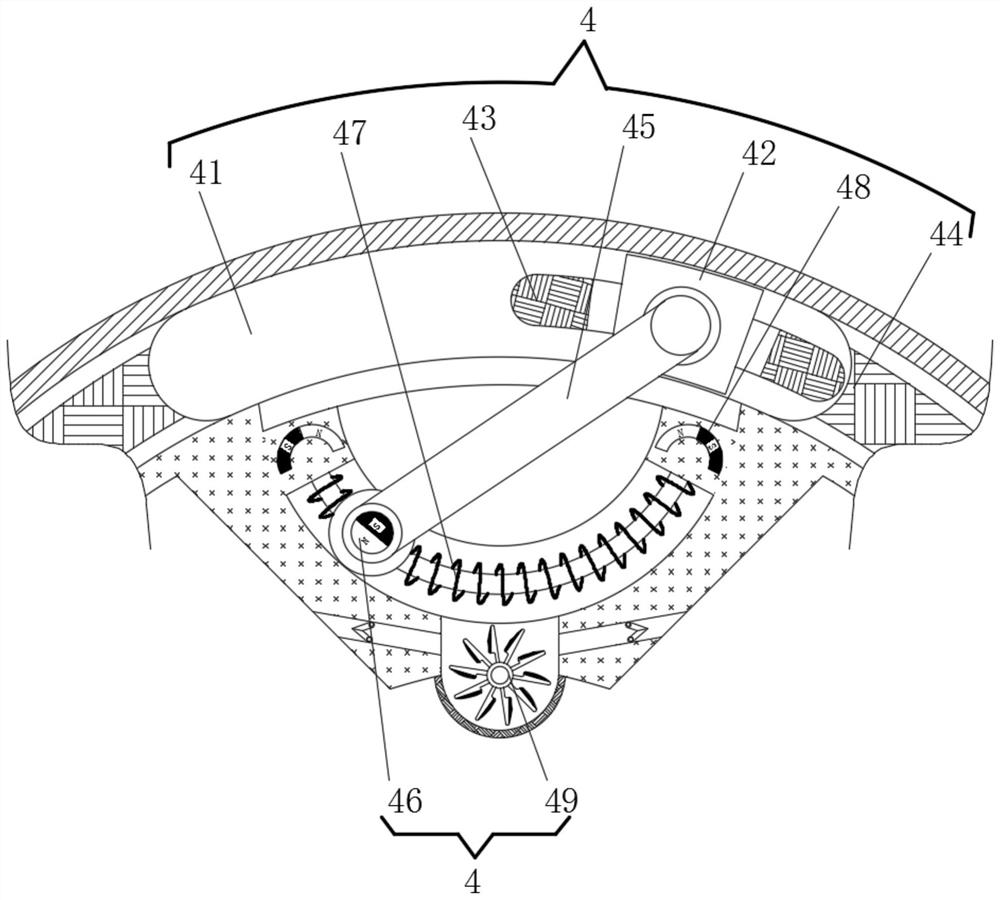

[0027] see Figure 1-4 , a main shaft protection device for avoiding lateral inclination and reducing vibration, comprising a frame 1, a movable chamber 2 is provided at the center of the inner circle of the frame 1, and a rotating mechanism 3 is rotatably connected to the center of the movable chamber 2, and the frame 1 is far away from the movable The side of the cavity 2 is slidingly connected with a trigger mechanism 4, and the side of the trigger mechanism 4 is fixedly connected with a support mechanism 5. The rotating mechanism 3 includes a rotating shaft 31, a supporting bearing 32, and a push rod 33. The outer side of the rotating shaft 31 is rotationally connected with a supporting bearing 32. The side of the bearing 32 away from the rotating shaft 31 is rotatably connected with a push rod 33. The offset of the rotating shaft 31 can push the push rod 33 through the support bearing 32, and the push rod 33 drives the push plate 52 to slide. The side of the support bearin...

Embodiment 2

[0029] see figure 1 , 5 6. A main shaft protection device that avoids lateral inclination and reduces vibration, including a frame 1, a movable chamber 2 is provided at the center of the inner circle of the frame 1, and a rotating mechanism 3 is rotatably connected to the center of the movable chamber 2, and the frame 1 A trigger mechanism 4 is slidingly connected to the side far away from the movable chamber 2, and a support mechanism 5 is fixedly connected to the side of the trigger mechanism 4. The rotating mechanism 3 includes a rotating shaft 31, a supporting bearing 32, and a push rod 33. The outer side of the rotating shaft 31 is rotationally connected to a supporting bearing 32. The side of the support bearing 32 away from the rotating shaft 31 is rotationally connected with a push rod 33, the offset of the rotating shaft 31 can push the push rod 33 through the support bearing 32, the push rod 33 drives the push plate 52 to slide, and the side of the support bearing 32...

Embodiment 3

[0031] see Figure 1-6, a main shaft protection device for avoiding lateral inclination and reducing vibration, comprising a frame 1, a movable chamber 2 is provided at the center of the inner circle of the frame 1, and a rotating mechanism 3 is rotatably connected to the center of the movable chamber 2, and the frame 1 is far away from the movable The side of the cavity 2 is slidingly connected with a trigger mechanism 4, and the side of the trigger mechanism 4 is fixedly connected with a support mechanism 5. The rotating mechanism 3 includes a rotating shaft 31, a supporting bearing 32, and a push rod 33. The outer side of the rotating shaft 31 is rotationally connected with a supporting bearing 32. The side of the bearing 32 away from the rotating shaft 31 is rotatably connected with a push rod 33. The offset of the rotating shaft 31 can push the push rod 33 through the support bearing 32, and the push rod 33 drives the push plate 52 to slide. The side of the support bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com