Anti-falling sealing structure for joint of ductile cast iron pipe

A ductile iron pipe, sealing structure technology, applied in the direction of pipe/pipe joint/pipe fitting, sleeve/socket connection, through components, etc., can solve the problems of water waste, gaps in the connection, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

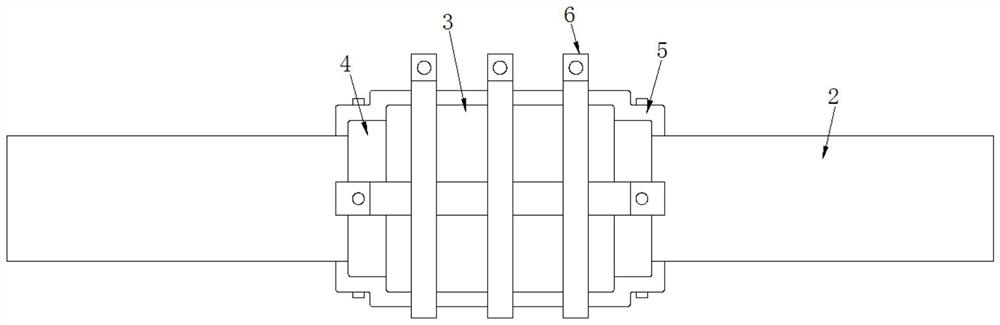

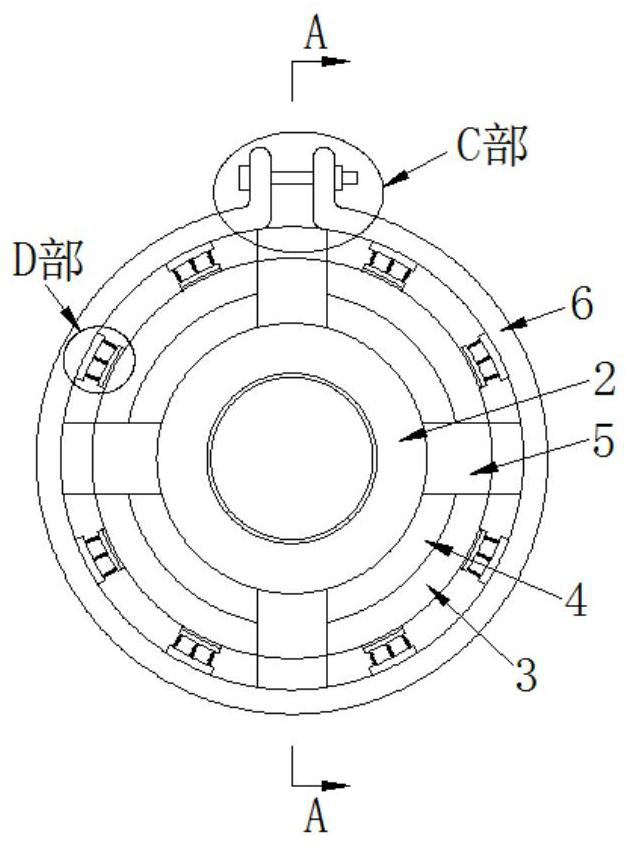

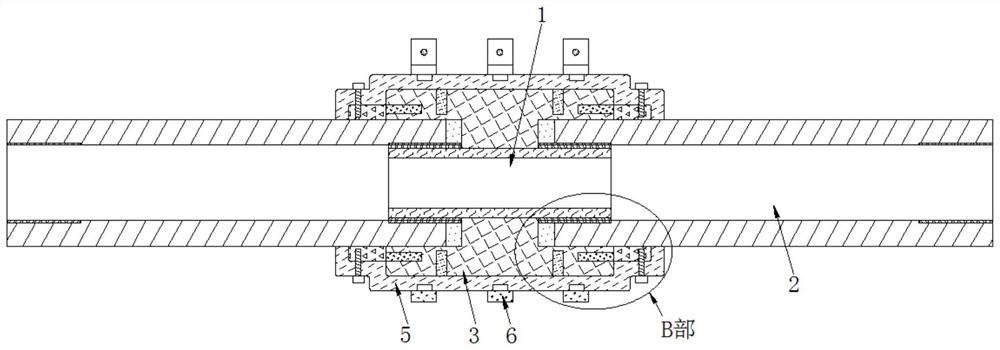

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

[0036] see as Figure 1-Figure 6 As shown, the technical solution adopted in this specific embodiment is: it includes a connecting pipe 1, the connecting pipe 1 is arranged between two adjacent pipe bodies 2 on the left and right, and the connecting pipe 1 and the pipe body 2 are screwed together set up;

[0037] It also contains:

[0038] Limiting platform 3, the limiting platform 3 is sleeved and fixed on the connecting pipe 1 by welding, and the limiting platform 3 is arranged between the left and right pipe bodies 2, and the inner walls of the left and right sides of the limiting platform 3 are provided with There is an annular groove 3-1, and the pipe body 2 is rotatably inserted in the annular groove 3-1;

[0039] There are two limit rings 4, the two limit rings 4 are respectively sleeved and welded on the corresponding pipe body 2, and the limit rings 4 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com